- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

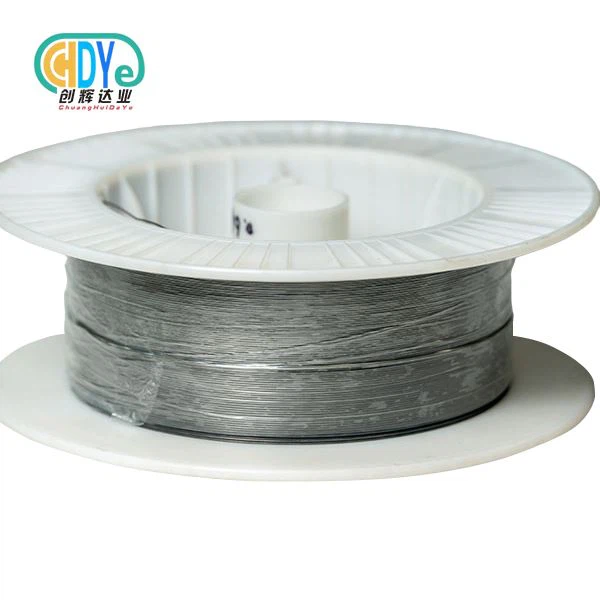

Tantalum Wire For Sale

Shaanxi Chuanghui Daye Metal Material CO.,Ltd provide tantalum wire for sale with high purity and various sizes.

Product Introduction

Tantalum wire, as a kind of filamentous tantalum material, is crafted from high-purity tantalum powder through advanced plastic processing methods, including rolling, drawing, and extrusion.Shaanxi Chuanghui Daye Metal Material CO.,Ltd provide tantalum wire for sale with high purity and various sizes.

Processing method

Powder Metallurgy Process: Raw Material (Tantalum Powder) → Mixing → Forming → Vertical Melting → Rotary Forging → Intermediate Annealing → Drawing → Annealing of Finished Products → Quality Inspection → Packaging and Storage.

Smelting Process: Raw Material (Tantalum Powder) → Mixing → Forming → Pre-Sintering → Electron Beam Melting → Fine Forging → Intermediate Annealing → Rotary Forging → Intermediate Annealing → Drawing → Annealing of Finished Products → Quality Inspection → Packaging and Storage.

Features for tantalum wire

Corrosion resistance: Tantalum wire has good corrosion resistance and can be used in extreme environments. It has good corrosion resistance to most acids and bases, such as at 150 ° C, it will not corrode in any concentration of hydrochloric acid, nitric acid, phosphoric acid, and organic acids, but is sensitive to hydrofluoric acid and mixtures of hydrofluoric acid and nitric acid

Conductivity: Tantalum wire has good conductivity and is suitable for use in electronic components. For example, it can be used to manufacture electrodes in electronic components such as capacitors, inductors, and resistors

Low Thermal Expansion Coefficient: The wire maintains dimensional stability under temperature changes, ideal for precision applications.

Processability: Tantalum wire can be processed at high temperatures and is easily combined with materials such as ceramics and glass, making it suitable for making other components of electronic devices

High Melting Point: With a melting point of 3017°C, tantalum wire can withstand extreme temperatures without losing its structural integrity.

High Melting and Boiling Points: Its thermal stability at high temperatures makes it a reliable choice for high-temperature applications.

Application Advantages

Tantalum Wire For Sale provides outstanding performance in high-temperature, vacuum, and corrosive environments. It exhibits excellent chemical stability, a high melting point, and superior resistance to most acids except hydrofluoric acid. These properties make it ideal for use in aerospace components, chemical processing equipment, medical devices, and electronic capacitors. The wire also maintains excellent ductility and conductivity, making Tantalum Wire For Sale a preferred choice for precision applications in semiconductor and energy industries.

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

The production process of Tantalum Wire For Sale follows international standards such as ASTM B365, ensuring reliable quality and consistent performance:

Raw Material Selection: Only high-purity tantalum ingots are selected to guarantee uniform composition.

Melting and Refining: Vacuum or electron beam melting eliminates impurities and ensures material stability.

Hot and Cold Working: Rolling, forging, and drawing processes refine the structure and improve mechanical properties.

Annealing: Controlled annealing enhances flexibility, ductility, and corrosion resistance.

Surface Treatment & Inspection: Final polishing and cleaning ensure a bright, defect-free surface before packaging.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Every batch of Tantalum Wire For Sale undergoes strict inspection under our ISO 9001:2015 quality system. Quality assurance measures include:

Chemical composition testing by optical emission spectrometry.

Mechanical property evaluation including tensile strength and elongation.

Non-destructive inspection using ultrasonic or eddy current techniques.

Surface quality check to detect defects, cracks, or contamination.

R&D and Customization

Shaanxi Chuanghui Daye’s R&D team is committed to continuous improvement in rare metal processing. For Tantalum Wire For Sale, we offer flexible customization to meet various industrial needs:

Adjustable diameters from 0.1 mm to 5.0 mm.

Custom purity levels from 99.95% to 99.99%.

Tailored mechanical properties for special environments.

Our experts also provide design consultation and support for prototype development and testing.

Packaging & Global Logistics

Each coil or spool of Tantalum Wire For Sale is vacuum-packed or wrapped in anti-rust film, cushioned with foam, and placed inside a sturdy export wooden case. Each package includes clear labeling with specifications, batch number, and quality certification. We provide reliable air, sea, and land transportation options to over 50 countries, ensuring safe and timely delivery worldwide.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Shaanxi Chuanghui Daye offers OEM/ODM production to help clients achieve custom engineering goals. Services include:

Manufacturing according to customer drawings or technical parameters.

Small-batch or mass production with fast turnaround.

Surface finishing, spooling, and special packaging options.

Full traceability from material selection to delivery.

Inspection Process

Before shipment, all products pass through multi-stage inspection:

Incoming raw material verification for purity and certification.

In-process dimensional control during rolling and drawing.

Mechanical and surface tests after annealing.

Final quality audit to ensure conformance with ASTM and customer specifications.

Why Choose Us

30+ years of expertise in rare metal manufacturing.

ISO 9001:2015 certified production system.

Fast 7-day delivery for standard orders.

Global export to 50+ countries with proven reliability.

Competitive pricing with professional OEM support.

|

|

|

|

|

|

FAQs

Q1: What is the purity level of your tantalum wire?

A1: The standard purity is 99.95%, and ultra-high purity 99.99% can be customized.

Q2: What size range do you produce?

A2: We offer diameters from 0.1 mm to 5.0 mm, with special sizes available upon request.

Q3: Do you support sample or prototype orders?

A3: Yes, we provide small-batch and prototype orders for research and testing.

Q4: How long does production and delivery take?

A4: Standard items are typically shipped within 7 days; customized sizes require additional lead time.

Q5: Which industries commonly use your products?

A5: They are used in aerospace, electronics, chemical processing, and medical device manufacturing.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email