- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Niobium Alloy Plate

2.Standard: ASTM B393

3.Surface: Polished, annealed, Cold-rolled bright

4.Grade: UNS R04200, UNS R04210 ,C103 Alloy, 45Nb Alloy (Nb-55Ti), Nb-7.5Ta, Nb-47Ti, Nb-50Ti

Product Introduction

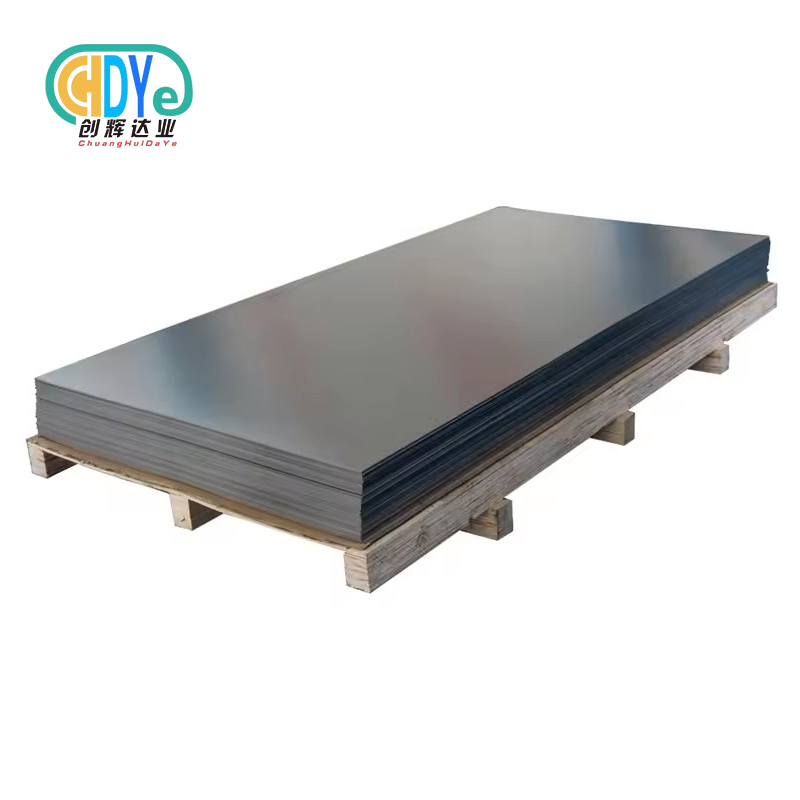

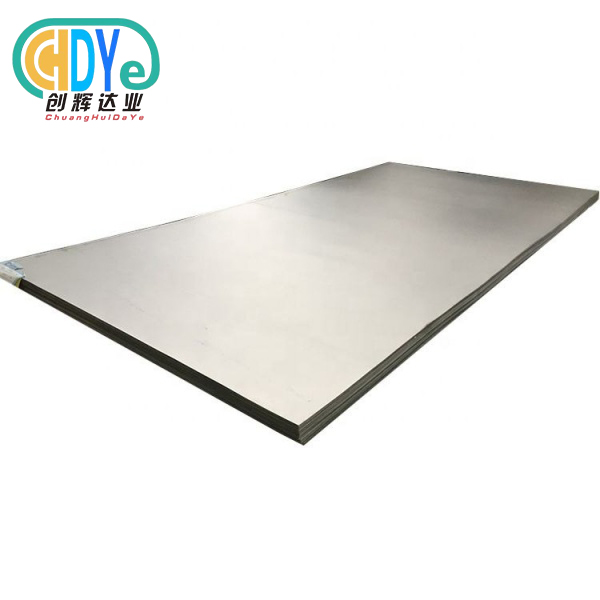

Chdymetal offers top-quality niobium alloy plate with the shortest lead time and competitive prices, normal size we have in stock all year round and if you need customized service pls feel free to contact us.

The niobium alloy plate is produced by rolling high-purity niobium metal, which exhibits excellent ductility. They have excellent properties such as high melting point, high strength, high electrical conductivity, high superconductivity, and high corrosion resistance.

1. Size: 0.5- 3mm * thick x W x L

2. Standard: ASTM B393

3. Surface: Polished, annealed, Cold-rolled bright

4. Grade: UNS R04200, UNS R04210 ,C103 Alloy, 45Nb Alloy (Nb-55Ti), Nb-7.5Ta, Nb-47Ti, Nb-50Ti

|

Product Name |

Niobium alloy plate |

|

Material |

Pure niobium and niobium alloy |

|

Dimension |

As per your request |

|

Grade |

R04200.R04210,R04251,R04261 |

|

Characteristic |

Melting point : 2468℃ Boiling point : 4744℃ |

|

Application |

Widely used in chemical, electronics, aviation and aerospace fields |

|

Product Features |

Excellent Corrosion Resistance Good resistance to effect of heat |

|

Packing |

Foam material inside, wooden box outside |

|

Payment terms |

30% TT in advance, 70% balance before shipment |

|

Delivery time |

stock size within 1-5days, production time 15 working days |

|

Sample |

Sample order are supported |

Niobium and Niobium Alloy UNS Grade

UNS R04200 Reactor grade unalloyed niobium

UNS R04210 Commercial grade unalloyed niobium

UNS R04251 Reactor grade Niobium-1% zirconium

UNS R04261 Commercial grade Niobium-1% zirconium

Niobium alloy plate Packing

Niobium alloy plate wrapped in woven bag, and the external wooden packing cable ties are tightened to ensure safety during transportation.

If you need customized service pls just feel free to contact us. E-mail: info@chdymetal.com/ Mob: 86-18049386902

Application Advantages

The Niobium Alloy Plate is known for its outstanding corrosion resistance, high melting point, and excellent formability. It performs exceptionally well in harsh chemical and high-temperature environments, making it a preferred material for aerospace components, chemical reactors, and electronic equipment. With its superior strength-to-weight ratio and stability, the Niobium Alloy Plate ensures durability and reliability in advanced engineering applications. It is also widely used in superconducting materials, medical imaging systems, and high-performance vacuum devices.

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

The production of Niobium Alloy Plate at Shaanxi Chuanghui Daye Metal Material Co., Ltd. involves a series of precision-controlled steps:

- Raw Material Selection: Only high-purity niobium and alloying elements are sourced from verified suppliers.

- Melting: Electron beam or vacuum arc melting ensures homogeneous alloy composition.

- Hot Forging & Rolling: Advanced rolling equipment provides precise plate thickness and improved mechanical properties.

- Annealing & Leveling: Controlled annealing enhances ductility and removes internal stress.

- Surface Treatment & Inspection: Final polishing, pickling, and quality inspection ensure flawless surface finish and dimensional accuracy.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Every Niobium Alloy Plate undergoes rigorous inspection at multiple stages of production. Quality control includes raw material verification, chemical composition analysis, tensile testing, ultrasonic flaw detection, and final visual inspection. The entire process strictly complies with ISO 9001:2015 standards to guarantee uniform quality and high performance. Certificates of conformity and detailed inspection reports are provided with each batch to ensure full traceability and customer confidence.

R&D and Customization

Our research and development team continuously works to enhance the performance and versatility of the Niobium Alloy Plate. Through metallurgical innovation and advanced processing techniques, we develop customized alloys for specific applications such as high-temperature environments, superconducting systems, and precision instruments. Clients can request tailored compositions, mechanical properties, and surface finishes to meet specialized project requirements.

Packaging & Global Logistics

Each Niobium Alloy Plate is carefully packaged to ensure safe delivery worldwide. Standard packaging includes vacuum sealing, anti-corrosion protection, and reinforced wooden crates suitable for long-distance shipping. Clear labeling and documentation accompany every shipment, allowing smooth customs clearance. With partnerships in over 50 export markets, our logistics network ensures fast, reliable, and cost-effective transportation by air, sea, or land.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Shaanxi Chuanghui Daye Metal Material Co., Ltd. offers complete OEM and ODM services for Niobium Alloy Plate products. We provide custom dimensions, grades, and finishes based on technical drawings or project requirements. Prototype and small-batch production are available to support R&D needs. Our engineering team works closely with clients from design consultation to after-sales service, ensuring optimal material solutions for every industry.

Inspection Process

- Material Verification: Ensure chemical purity and traceability of all raw materials.

- Dimensional Control: Check thickness, flatness, and tolerance per customer requirements.

- Mechanical Testing: Conduct tensile, hardness, and elongation tests.

- Surface Evaluation: Perform visual and ultrasonic inspections for surface integrity.

- Final Certification: Issue quality reports and compliance documentation before shipment.

Why Choose Us

- Over 30 years of expertise in rare metal manufacturing

- Strict ISO 9001:2015 quality management system

- Fast lead time with 7-day delivery for standard items

- Customized production with OEM/ODM support

- Trusted by global clients in 50+ countries for reliability and excellence

|

|

|

|

|

|

FAQs

Q1: What is the purity level of your Niobium Alloy Plate?

A1: The standard purity exceeds 99.9%, meeting ASTM and customer-specific standards.

Q2: Can you provide customized thickness and dimensions?

A2: Yes, custom sizes and tolerances are available according to your drawings or project needs.

Q3: What surface finishes can you offer?

A3: We provide polished, matte, and custom surface treatments based on the intended application.

Q4: Do you provide test certificates?

A4: Yes, each order includes a full quality inspection report and chemical analysis certificate.

Q5: What is your typical delivery time?

A5: Standard products are shipped within 7 days, while customized orders depend on production

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email