- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

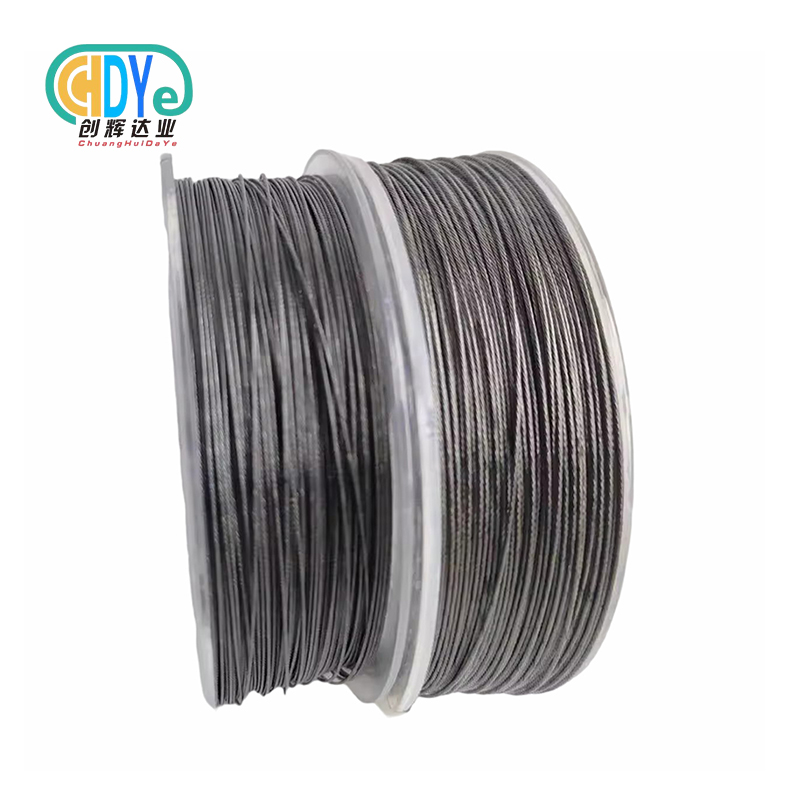

Titanium Anode Basket

2.Size:Customized accept your CAD or PDF drawing

Product Introduction

Titanium anode baskets are a kind of hanging tool used to install anodes on electroplating equipment. Titanium anode Baskets, mainly cylindrical or rectangular, produced according to specific customer's requirements.

Anode baskets are available in a few shapes and sizes, and also we can provide customized service ,just provide your CAD or PDF drawing.

Optional hook designs are available – depending on basket's required amperage requirement. Our offered baskets are manufactured using TIG welding process which enhances continuous and good current capacity and sturdy construction.

Application Advantages

Nickel Plating

Chromium Plating

Copper Plating

Silver Plating

Zinc Plating

Brass Plating

Tin Plating

Anodising

Chemical industries

Be used in a wide range of industries.

Seawater electrolysis

Marine aquaculture

Chlor-alkali industry

Cathodic protection

Electroplating industry

Non-ferrous metal electrolytic extraction

Manufacturing & Process Flow

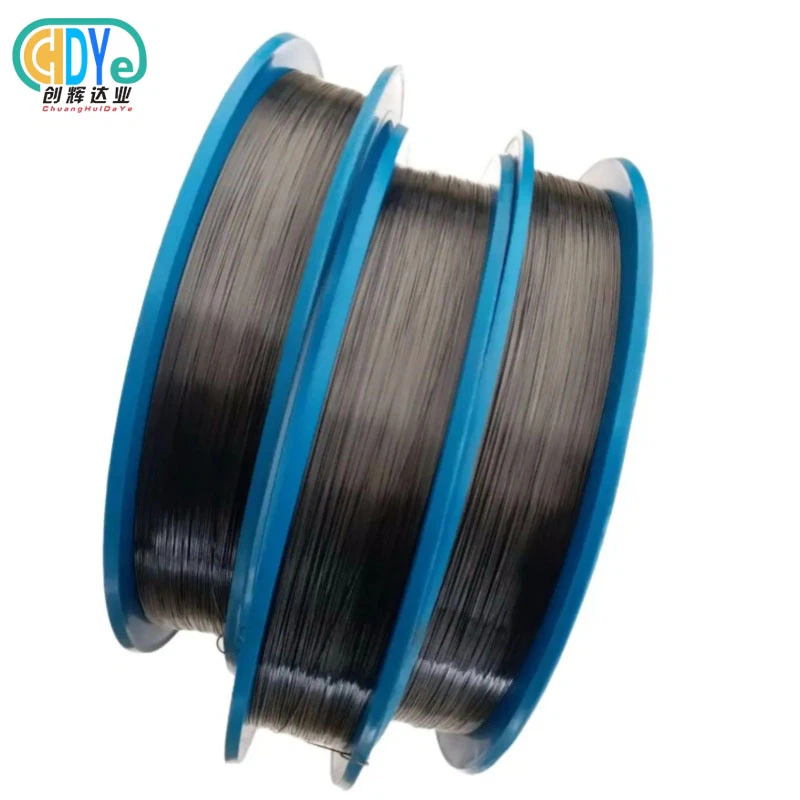

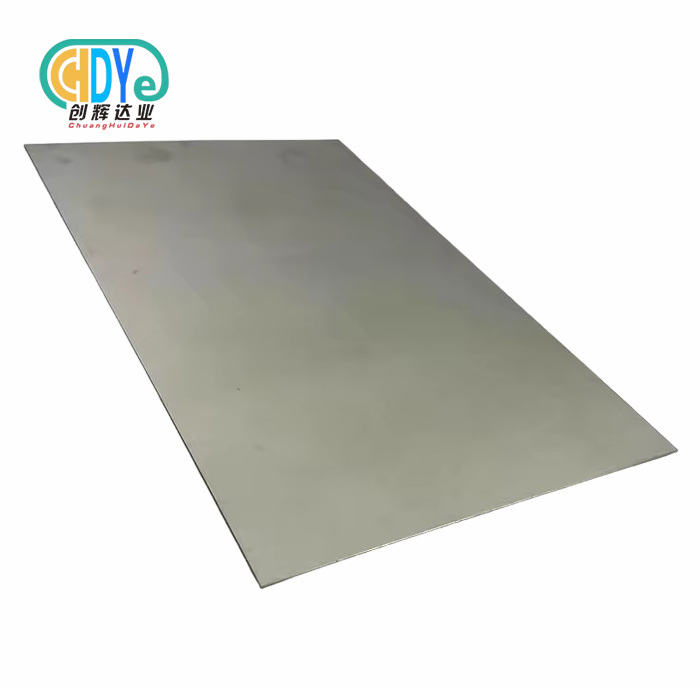

1.Substrate selection: The core material of titanium anode is high-purity titanium material, usually selected with a purity of 99.5% or above. High purity titanium material has excellent corrosion resistance, high strength, and lightweight characteristics, which can maintain stable physical and chemical properties in harsh environments

2. Mechanical processing: including cutting, drilling, bending and other processes to shape titanium materials into the desired shape and size. For example, the titanium anode used in electrolytic cells usually needs to be processed into a plate or mesh structure to meet the requirement of uniform current distribution.

3. Welding: Cut and drill holes according to customer drawings before welding. Welding mainly adopts argon arc welding method to ensure that the same materials can be firmly welded together

4. Assembly: Assemble the welded components to form a complete titanium anode mesh basket structure.

5. Quality inspection: Conduct strict quality inspection on the manufactured titanium anode mesh basket, including chemical composition analysis, mechanical performance testing, corrosion resistance testing, and appearance inspection.

6.Packaging: After passing the quality inspection, appropriate packaging and labeling are carried out to ensure the safety of the product during transportation and storage.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Shaanxi Chuanghui Daye Metal Material Co., Ltd. follows rigorous quality control measures throughout the production of Titanium Anode Baskets.

Quality Assurance Steps:

Raw Material Inspection: All titanium materials undergo thorough testing to ensure they meet the required mechanical and chemical properties.

Coating Adhesion Test: Each anode basket’s MMO coating is tested for uniformity and adhesion strength.

Electrochemical Testing: Baskets are subjected to rigorous testing to validate their electrochemical properties, including current efficiency and stability under operational conditions.

Dimensional & Visual Inspection: Each unit is checked for precise dimensions and visually inspected for any defects such as cracks, deformations, or coatings inconsistencies.

Packaging Verification: Final inspection ensures that each basket is securely packaged to prevent any shipping damage.

R&D and Customization

Our R&D team is dedicated to improving the performance and functionality of Titanium Anode Baskets, constantly innovating to meet the evolving needs of the market.

Research Focus Areas:

Development of more durable and efficient coatings to enhance the anode’s electrochemical performance and extend service life.

Optimization of basket designs to improve handling, weight reduction, and adaptability to various electrolytic processes.

Exploration of alternative materials or hybrid technologies to meet specific industry demands, such as in food processing, pharmaceuticals, and wastewater treatment.

Customization:

Sizes: We provide baskets in various sizes, including small, medium, and large, tailored to your needs.

Special Designs: We can produce baskets with specific grid structures or handles to ensure they fit seamlessly into your system.

Packaging & Global Logistics

We understand the importance of safe and timely delivery for every order of Titanium Anode Baskets. Therefore, our packaging and logistics processes are designed to ensure the products arrive safely at their destination.

Packaging Features:

Vacuum Sealing or Anti-rust Film: Protects the anode basket from corrosion during storage and transport.

Foam Protection: Prevents damage to the structure or coating during transit.

Export Standard Wooden Crates: Each basket is securely packed in crates that comply with international export standards, ensuring product integrity.

Logistics Solutions:

Global Shipping: We provide flexible and reliable international shipping solutions, including air, sea, and land transportation.

Timely Delivery: Our standard delivery time is 7 days, and we offer expedited shipping for urgent orders.

Tracking Services: Real-time tracking available for all shipments to ensure peace of mind for our clients.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

We offer full OEM and ODM services to meet the diverse needs of our global customers. Whether you require a custom design or specific features, we can tailor our Titanium Anode Baskets to suit your exact requirements.

Custom Services Include:

Design & Size Customization: Tailoring baskets to fit specific electrochemical tanks or systems.

Material and Coating Options: Choosing the right titanium grade and MMO coating system for optimal performance in your unique environment.

Prototyping & Small-Batch Production: For clients needing small quantities or trial runs.

Private Labeling: We can add your logo or branding to the baskets upon request.

Technical Consultation & After-Sales Support: We provide ongoing support throughout the product lifecycle, from installation to maintenance.

Inspection Process

The Titanium Anode Basket undergoes a comprehensive inspection process to ensure it meets our high standards.

Inspection Stages:

Raw Material Verification: Chemical composition and mechanical properties are tested to ensure the titanium meets industry standards.

Coating Testing: The MMO coating’s adhesion, uniformity, and electrochemical behavior are rigorously tested.

Assembly Inspection: After assembly, baskets are checked for quality and alignment with customer specifications.

Functional Testing: Baskets are tested in simulated conditions to evaluate performance before delivery.

Final Packaging Check: Ensuring that the anode baskets are securely packed and labeled for shipment.

Why Choose Us

30+ Years of Expertise: Our company is a leader in the production of Titanium Anode Baskets and other rare metal components.

ISO 9001:2015 Certification: We adhere to strict quality management standards for all our products.

Customization Options: Tailored solutions for unique industrial applications.

Global Reach: Serving customers in over 50 countries with reliable delivery and competitive prices.

Excellent Customer Support: Our team of experts is always ready to provide technical advice and assistance.

Fast & Reliable Shipping: We offer 7-day delivery for standard products and fast shipping worldwide.

|

|

|

|

|

|

FAQs

Q1: What industries use Titanium Anode Baskets?

A1: Titanium Anode Baskets are commonly used in electroplating, wastewater treatment, and chlor-alkali production.

Q2: How long do these baskets last?

A2: Under normal conditions, Titanium Anode Baskets can last up to 10–20 years depending on the application.

Q3: Can the baskets be customized to fit my system?

A3: Yes, we provide custom sizes, shapes, and coating options based on your system's requirements.

Q4: What coatings are available for these baskets?

A4: We offer MMO coatings, including Ruthenium-Iridium, Iridium-Tantalum, and other specialized coatings based on your needs.

Q5: Are the baskets environmentally friendly?

A5: Yes, Titanium Anode Baskets are lead-free, non-toxic, and fully compliant with environmental regulations.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email