- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

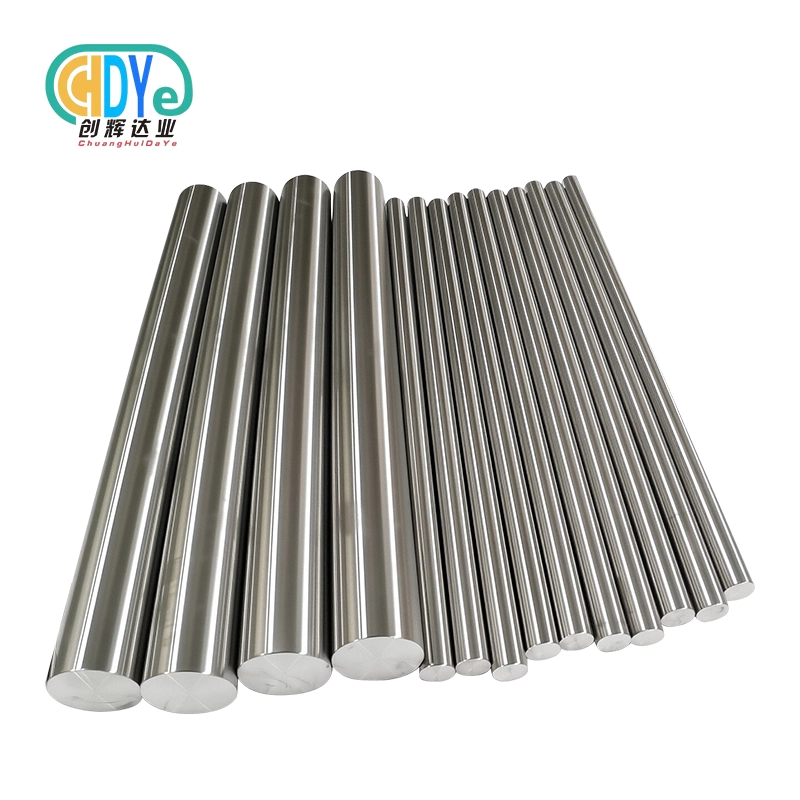

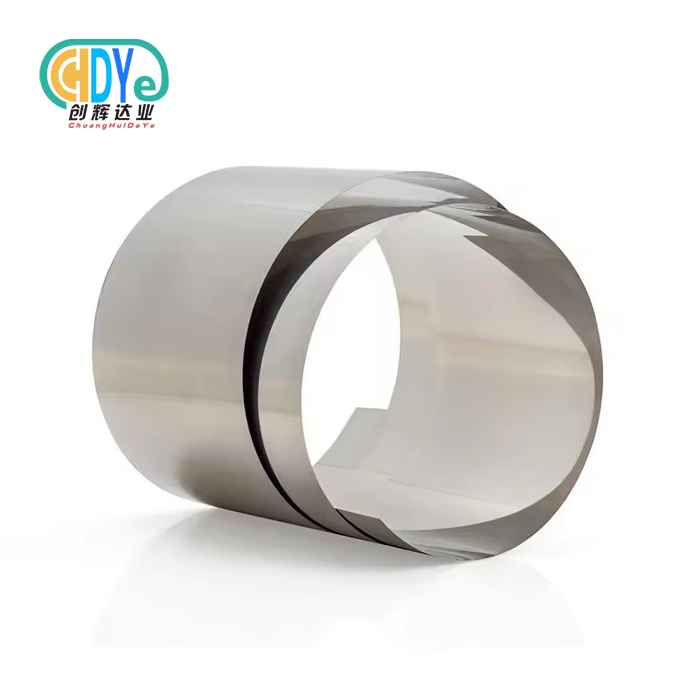

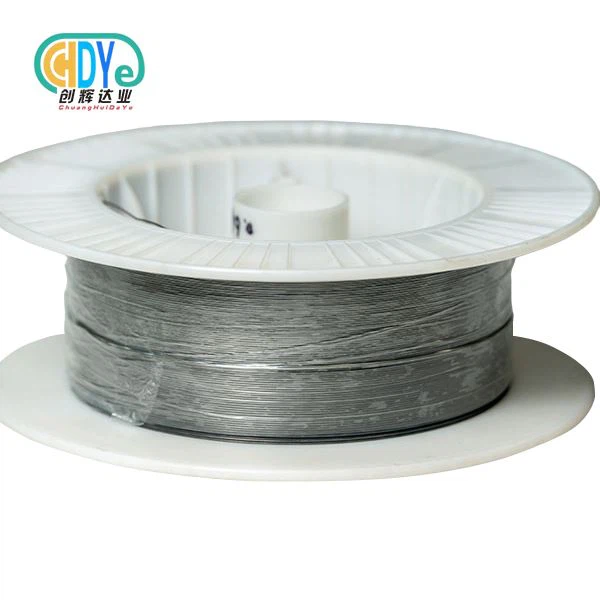

Titanium Alloy Wire

2.Various grade and material

3.Straight type and coil type are all ok

4.Free samples is available

Product Overview

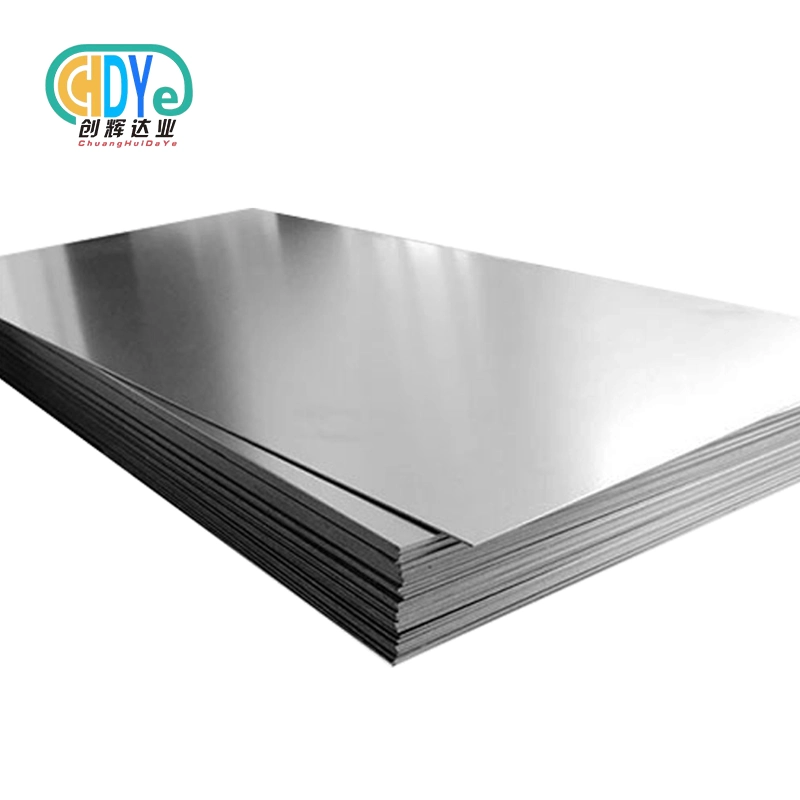

Shaanxi Chuanghui Daye Metal Material Co., Ltd. is a trusted global supplier of Titanium Alloy Wire, delivering precision-engineered solutions for demanding industries such as aerospace, medical, chemical, electronic, and marine engineering.

Located in Baoji, China’s “Titanium Capital,” we combine advanced metallurgical expertise, modern production lines, and strict quality control systems to produce wires that meet international standards including ASTM B863, AMS 4954, and ISO 9001:2015.

Each coil of our titanium alloy wire embodies our pursuit of strength, stability, and surface perfection. Whether for welding, medical implant fabrication, or precision spring manufacturing, Chuanghui Daye provides a material that performs reliably under the most challenging environments.

Specification

|

Item name |

Titanium alloy wire |

|

Specification |

Straight:Dia.: 1.0mm-5.0mm (0.04"-0.02", tolerance: +/-0.05mm, +/-0.002") |

|

Grade |

GR1, GR2, GR3, GR4, GR5, Ti6AL4V Eli, GR7, GR9, GR12, GR23, TC4, TC6, TC11, TC17, TC18 |

|

Application |

Chemical equipment, such as pipes, heat exchangers, evaporators, heaters, reaction kettles ect |

|

Surface |

Pickling polished |

|

Type |

Straight,Coil, Spool |

|

Processing |

Bar billets-hot rolling-drawing-annealing-strength-pickling |

|

Standard |

ASTM B863, AWS A5.16, ASTM F67, ASTM F136 |

|

Features |

1. Super elasticity good plasticity, with memory function |

Physical & Mechanical Performance

Our titanium alloy wire exhibits exceptional balance between strength, ductility, and corrosion resistance. The alloy microstructure is refined through multi-pass drawing and vacuum annealing, ensuring uniform grain distribution and high fatigue strength.

Key mechanical properties include:

- Excellent tensile-to-weight ratio

- High fatigue resistance under cyclic stress

- Non-magnetic and biocompatible characteristics

- Stable mechanical behavior across wide temperature ranges (-250°C to +400°C)

- Outstanding corrosion resistance against acids, alkalis, and seawater environments

These qualities make our wire suitable for both structural and functional applications where reliability is critical.

Product Highlights & Advantages

- Purity-Controlled Smelting – Using electron beam and vacuum arc furnaces, each melt achieves ultra-low inclusion and impurity levels.

- Dimensional Precision – Automated laser measurement ensures diameter accuracy within ±0.01 mm, meeting the strictest OEM standards.

- Superior Surface Finish – Mirror-polished and oxide-free surfaces ensure excellent welding performance and electrical conductivity.

- Mechanical Stability – Enhanced tensile strength and elasticity tailored for high-load and cyclic applications.

- Custom Alloy Solutions – Flexible combinations of Ti–Al–V, Ti–Pd, Ti–Mo, and Ti–Fe systems for corrosion or heat resistance optimization.

- Global Certification Support – Full documentation including mechanical, chemical, and ultrasonic test reports for international compliance.

- Fast and Reliable Supply Chain – Ready-to-ship inventory and 7–15 day lead time for standard grades.

Manufacturing & Process Flow

Our comprehensive production line integrates raw material purification, melting, hot and cold working, annealing, and precision drawing.

- Raw Material Selection – Certified titanium sponge or alloy ingot from reputable sources.

- Vacuum Melting – Double or triple VAR/EB furnaces refine and homogenize the alloy.

- Hot Forging & Rolling – Improve grain structure and density.

- Wire Drawing – Multi-pass drawing through precision dies ensures exact dimensions and roundness.

- Intermediate Annealing – Vacuum annealing relieves internal stress and enhances ductility.

- Straightening & Surface Treatment – Achieving bright, defect-free surfaces.

- Inspection & Testing – 100% NDT and dimensional verification before packaging.

Each wire undergoes strict process traceability to maintain full quality documentation.

|

|

|

|

|

|

|

|

Quality Control & Inspection

We follow a zero-defect quality principle supported by modern analytical instruments and experienced technicians.

Testing includes:

- Chemical Composition Analysis (ICP, spectrometer)

- Mechanical Tests (tensile, yield, elongation)

- Microstructure Examination (grain size, phase analysis)

- Ultrasonic & Eddy Current Detection

- Dimensional Inspection (laser micrometry)

- Surface Examination (visual + metallographic)

Our ISO 9001:2015 certification guarantees systematic quality assurance from melting to shipment.

Application Advantages

Our titanium alloy wire has proven reliability across multiple industrial sectors:

- Aerospace & Defense: Used in fasteners, structural tension elements, and control cable assemblies requiring strength and light weight.

- Medical & Dental: Fabrication of surgical implants, orthodontic wires, bone fixation devices, and biomedical instruments due to excellent biocompatibility.

- Chemical & Petrochemical: Perfect for heat exchangers, corrosion-resistant mesh, and reactors operating in acidic or saline environments.

- Electronics & Semiconductor: Utilized in sputtering targets, lead wires, and resistance components for high-vacuum systems.

- Automotive & Racing: Applied in performance springs, exhaust wires, and electrical connectors demanding heat endurance and weight savings.

- Marine Engineering: Excellent resistance to seawater corrosion ensures durability in underwater cables and submersible systems.

Our materials are currently serving clients in the United States, Germany, Japan, South Korea, France, and Singapore, among 50+ countries.

Be used in a wide range of industries.

Marine engineering

Medical implants

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

R&D and Customization

Our dedicated R&D team continuously works on alloy innovation and application-specific design.

We offer:

- Tailored alloy composition and wire geometry

- Prototype and trial-batch support

- Technical data consultation for weldability, formability, and fatigue behavior

- Custom surface treatment and packaging

- OEM/ODM branding service for distributors and manufacturers

Our engineers collaborate with customers from concept to production, ensuring optimal material performance for every project.

Packaging & Global Logistics

To ensure safe and contamination-free delivery, we adopt international export packaging standards:

- Inner Layer: Vacuum-sealed or anti-rust film wrapping

- Intermediate Layer: Foam cushioning for shock protection

- Outer Case: Fumigation-free plywood or steel-reinforced boxes

- Marking: Clear labeling with alloy grade, dimension, heat number, and batch code

We cooperate with major logistics providers (DHL, FedEx, UPS, COSCO) to provide air and sea delivery options ensuring timely arrival to your destination.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

Global Partnership & Case References

Chuanghui Daye has successfully supported major clients in:

- Aerospace sector: Supply of Ti-6Al-4V wire for control cable assemblies.

- Medical device manufacturing: Biocompatible wire for orthopedic applications in Europe.

- Chemical processing: Corrosion-resistant wire mesh for acid-handling systems in Southeast Asia.

Our consistent quality and responsive service have established long-term cooperation with global partners, reinforcing our reputation as a reliable source of titanium and rare metal materials.

Why Choose Us

- 30+ years of expertise in titanium metallurgy

- Full-process production from melting to precision drawing

- ISO-certified manufacturing and 100% traceability

- Competitive price-to-performance ratio

- Global logistics and after-sales support

- Fast turnaround with 7-day delivery for standard items

- Trusted by industrial buyers in 50+ countries

We don’t just supply titanium wire — we deliver engineering excellence and partnership value.

|

|

|

|

|

|

FAQ

Q1: What surface conditions are available?

We offer bright, pickled, polished, and oxide-free finishes to meet different welding or medical requirements.

Q2: Can you provide custom mechanical properties?

Yes. We can adjust heat treatment and alloy composition to meet specific tensile or yield strength targets.

Q3: Do you provide test certificates?

Absolutely. Every batch comes with EN 10204 3.1 Material Test Certificate, including mechanical, chemical, and NDT results.

Q4: What is your typical lead time?

For standard specifications, we ship within 7–10 days. Custom production usually requires 20–25 days.

Q5: What’s your export experience?

We export to more than 50 countries with long-term partners in aerospace, medical, and industrial sectors worldwide.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email