- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Titanium Anode Plate for Electrodialysis

Product Introduction

Electrodialysis method, which using function of electric field, force ions attracted to the electrode, ions density in the middle of electrode will be reduced to make fresh water. Normally any ion in the water is free through exchange membrane unless synthetic macromolecular ion. The differences between electrodialysis and electrolysis are: discontinuous redox reaction for relatively low voltage and small current of electrodialysis; while electrolysis just the opposite. Electrodialysis is widely used for chemical industry, light industry, metallurgy, paper-making, desalination and environmental protection, etc.

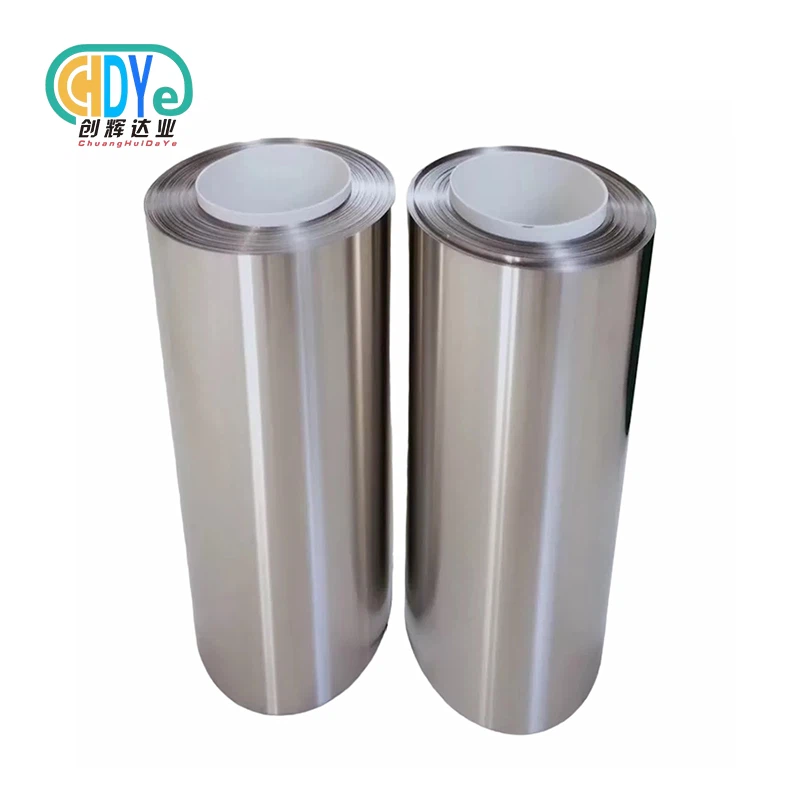

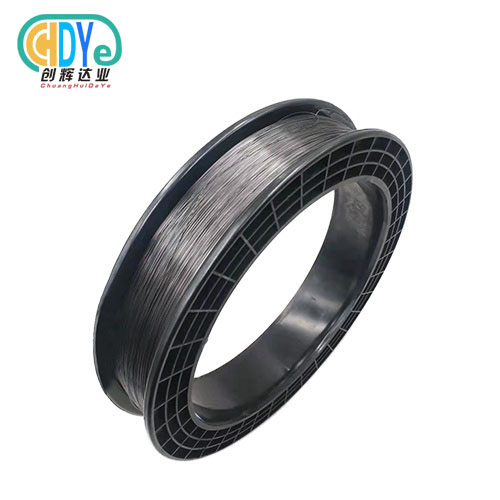

Titanium Anode plate use pure titanium mesh as substrate, has Long life span, reusability of substrate , reduce your cost . Sample order is supported.

1.Material: Titanium of Gr1 as base material, MMO as coating

2. Coating metal: Ru-Ir, Ir-Ta, Ru-Ir-Sn, PbO2, and Platinum

3. Coating thickness: ≥ 10μm

4. Type: sheet/mesh/tube/rod/Belt, different sizes and shapes available or according to client drawings

Working parameters:

Current density: ≤ 2,000 A/m2

Working current range: < 15,000 A/m2

Working environment: pH 0.1–14

Maximum content of fluoride ion: 200 PPM

Processing method: substrate treatment, sanding blasting, Acid Washing, Coating Brushing, High Temperature Sintering, Annealing

MOQ: Flexible

Sample Order: Acceptable

Titanium anode plate for electrodialysis Advantages:

1) Zero electrode distance help reduce cell voltage and power consumption

2) Increasing cell quantity under big current

3) Reduce electric resistance by increasing conductor bar diameter

Various type of titanium anode plate for Electrodialysis

|

|

|

|

Application Advantages

Titanium Anode Plates are widely used in electrodialysis for the desalination of water, water treatment, and chemical processing applications. Their robust performance, resistance to corrosion, and high current efficiency make them ideal for electrolytic separation processes.

Key Benefits:

- Corrosion Resistance: Titanium’s excellent resistance to chlorine and other aggressive chemicals ensures a long-lasting and reliable performance in electrochemical environments.

- High Electrolytic Efficiency: The Titanium Anode Plate ensures optimal ion exchange rates, making it ideal for efficient electrodialysis applications.

- Durability and Longevity: The anodes are designed to endure prolonged usage, even under extreme conditions, without significant degradation, ensuring a long lifespan.

- Stable Electrochemical Performance: Titanium anodes offer high performance, ensuring stable production even at high current densities.

- Cost-Effective Solution: High durability reduces the need for frequent replacement, ultimately leading to a reduction in operational costs.

Be used in a wide range of industries.

Seawater electrolysis

Marine aquaculture

Chlor-alkali industry

Cathodic protection

Electroplating industry

Non-ferrous metal electrolytic extraction

Manufacturing & Process Flow

Our Titanium Anode Plates for electrodialysis are manufactured through a precise and systematic process to ensure optimal performance.

Manufacturing Stages:

- Material Selection: Only high-grade titanium (Grade 1 or Grade 2) is used, ensuring optimal mechanical properties and corrosion resistance.

- Shaping & Cutting: Titanium sheets are carefully cut into the desired size and shape using advanced cutting technologies.

- Surface Preparation: The plates are polished and cleaned to remove any surface contaminants, ensuring the coating adheres securely.

- Coating Application: A mixed-metal oxide (MMO) coating is applied to the surface to enhance electrochemical performance, especially for chlorine evolution in electrodialysis.

- Curing: The coated plates undergo a curing process to harden the MMO coating, ensuring it is tightly bonded to the titanium surface.

- Assembly: If needed, additional components like connectors or mounting brackets are added for final assembly.

- Final Inspection: The plates undergo a rigorous inspection to ensure quality and functionality, confirming that they meet client specifications.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Titanium Anode Plates for electrodialysis undergo strict quality control to ensure performance and reliability.

Quality Control Procedures:

- Raw Material Inspection: All titanium materials are subjected to comprehensive testing to ensure compliance with ASTM, ISO, and GB standards.

- Coating Testing: The MMO coating is tested for adhesion strength, uniformity, and electrochemical stability under actual operating conditions.

- Electrochemical Testing: The plates are tested for current efficiency, voltage drop, and corrosion resistance in typical electrochemical environments.

- Dimensional and Visual Inspection: We ensure that all dimensions of the plates adhere to customer requirements and perform visual checks to detect surface defects such as cracks or coating irregularities.

- Final Packaging Inspection: Before packaging, each plate undergoes a thorough check to confirm its condition and readiness for shipment.

R&D and Customization

At Shaanxi Chuanghui Daye, we continuously innovate to meet the evolving demands of the electrodialysis industry. Our R&D team focuses on improving the performance and efficiency of our Titanium Anode Plates.

Key Areas of Focus:

Coating Optimization: Research into alternative coatings and new formulations to enhance efficiency and longevity under harsh operating conditions.

Customization:

- Custom Sizes and Shapes: Plates can be designed to fit specific electrodialysis systems or chambers.

- Specific Coating Types: Depending on the customer’s application, we can apply specialized coatings to enhance performance, such as Ruthenium-iridium for increased corrosion resistance in chlor-alkali applications.

- Prototype Production: We provide prototype and small-batch production to meet unique customer needs.

Packaging & Global Logistics

We ensure that all Titanium Anode Plates are safely packaged and delivered to global destinations efficiently.

Packaging Features:

- Anti-Rust Protection: Plates are wrapped with anti-rust film or placed in vacuum-sealed bags to protect them from corrosion during transport.

- Foam Cushioning: Extra protection is provided with foam padding to safeguard the plates from any damage during handling.

- Export-Standard Wooden Boxes: Plates are packed in wooden crates that comply with international export standards, ensuring their safety during long-distance shipping.

Global Logistics Solutions:

- Flexible Shipping Options: We offer air, sea, and land transport, depending on the urgency and destination.

- Timely Delivery: We ensure delivery within 7 days, with fast shipping options for urgent orders.

- Tracking & Support: Customers are provided with tracking details to monitor the progress of their shipments in real-time.

|

|

|

|

|

|

|

|

|

|

|

|

OEM & Customization Service

We offer OEM and ODM services to meet the specific needs of our global customers.

Custom Services Include:

- Design & Size Adjustments: Custom shapes and sizes to fit your electrodialysis systems.

- Coating Customization: Choose from a range of coating options, such as MMO, Ruthenium-Iridium, and other specialized materials.

- Prototype Development: We can create prototypes for new projects or assist in developing small-batch productions.

- Labeling & Branding: Custom labeling and branding services for a unique identity.

Our dedication to customer satisfaction and our ability to deliver tailored solutions makes us a reliable partner in the global electrochemical industry.

Inspection Process

Our Titanium Anode Plates undergo a rigorous inspection to guarantee quality and performance.

Inspection Stages Include:

- Material Testing: Ensuring the titanium meets chemical and mechanical properties.

- Coating Adherence Testing: Verifying the adhesion and uniformity of the MMO coating.

- Electrochemical Efficiency Testing: Plates undergo testing to measure current efficiency and voltage stability.

- Dimensional Inspection: Ensuring all tolerances are within customer specifications.

- Final Product Review: A complete visual and functional inspection to verify the product’s readiness for shipment.

Why Choose Us

- 30+ Years of Experience: With over three decades of expertise in the rare metal industry, we are a trusted global supplier.

- ISO 9001:2015 Certification: We adhere to the highest quality management standards.

- Tailored Solutions: We provide customized Titanium Anode Plates to suit your specific electrodialysis needs.

- Fast Delivery: Our products are shipped worldwide, with 7-day delivery for standard orders.

- Reliable Customer Support: Our dedicated team offers technical advice, consultation, and after-sales support.

|

|

|

|

|

|

FAQs

Q1: What industries use Titanium Anode Plates for Electrodialysis?

A1: Electrodialysis is widely used in water desalination, chemical processing, and wastewater treatment industries.

Q2: What coating options are available for Titanium Anode Plates?

A2: We offer MMO coatings, including Ruthenium-Iridium, and other specialized coatings based on your application.

Q3: How long do Titanium Anode Plates last?

A3: With proper maintenance, these plates can last up to 10–20 years, depending on operating conditions.

Q4: Can I get a custom-size Titanium Anode Plate for my system?

A4: Yes, we provide custom sizes and shapes to fit your specific system and requirements.

Q5: Are these plates suitable for harsh chemical environments?

A5: Yes, Titanium Anode Plates are highly resistant to corrosion and can withstand aggressive chemicals such as chlorine.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email