- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

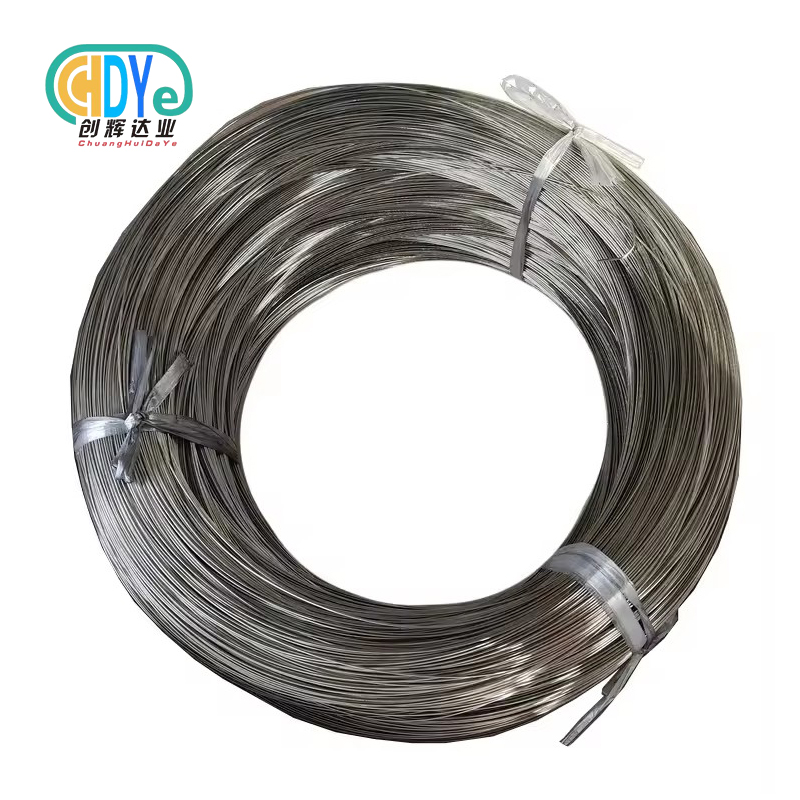

Titanium Fasteners

Specification: M2~M25×L or as your request

Standard: GB DIN ISO

Packing methods:cartons or as customer's request

Product Overview

Titanium Fasteners are essential components engineered for strength, corrosion resistance, and lightweight performance. Manufactured by Shaanxi Chuanghui Daye Metal Material Co., Ltd., these fasteners are made from high-grade titanium and titanium alloys that comply with ASTM, ISO, DIN, and GB standards.

With over 30 years of industry experience, our company supplies titanium fasteners that combine precision, durability, and long service life—making them ideal for demanding industrial and engineering applications.

Available in a complete range of types, including titanium bolts, nuts, screws, washers, threaded rods, studs, and anchors, we offer both standard and custom solutions for projects requiring high mechanical integrity and corrosion resistance.

Titanium fasteners are fasteners made of titanium alloy materials, which have various advantages and a wide range of application fields.

Production method: Machining and manufacturing

Material: Gr1, Gr2, Gr5

Specification: M2~M25×L or as your request

Standard: GB DIN ISO

Packing methods:cartons or as customer's request

Advantages of Titanium Fasteners

1. Low density and high strength: The density of titanium alloy is much lower than that of steel material, but its strength and specific strength are higher. This makes the use of titanium fasteners significantly reduce mechanical mass and energy consumption, making it suitable for occasions that require weight reduction.

2. Strong corrosion resistance: Titanium alloy performs well in various corrosive media, such as seawater, wet chlorine gas, nitric acid, etc., and is particularly suitable for marine engineering and chemical fields.

3. Good heat resistance: Titanium alloy can maintain good mechanical properties at high temperatures and is suitable for high-temperature environments.

4. Non magnetic: Titanium alloy is completely non-magnetic and suitable for use in precision machinery and electronic devices, avoiding the influence of magnetic forces.

5. Low coefficient of thermal expansion and elastic modulus: Titanium alloys have low coefficient of thermal expansion and elastic modulus, and have high thermal fatigue performance.

6. Aesthetics: The surface of titanium metal can present multiple colors and has a unique appearance.

Technical Specifications

| Item | Specification | Description |

|---|---|---|

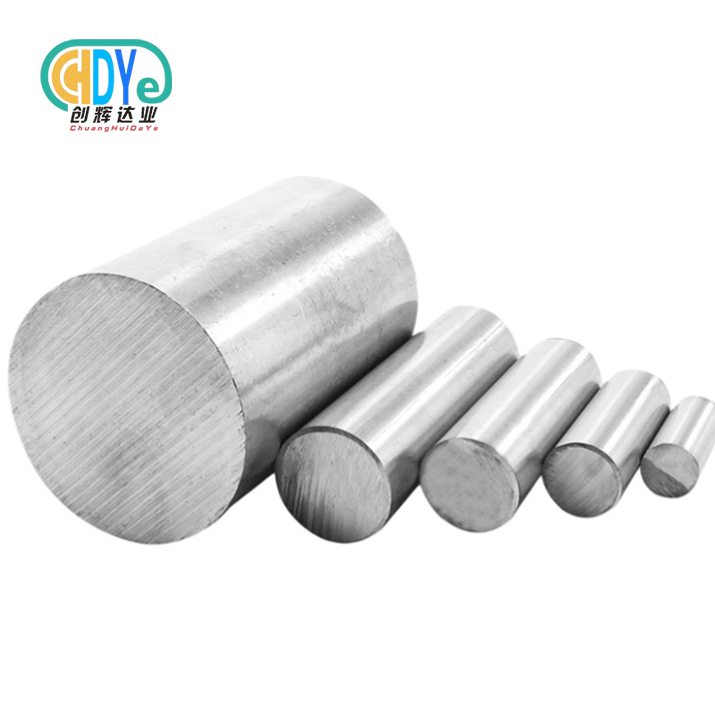

| Material Grades | Gr1, Gr2, Gr5 (Ti-6Al-4V), Gr7, Gr9, Gr12 | Pure and alloy titanium options |

| Size Range | M2 – M64 | Custom lengths and diameters |

| Standards | ASTM B348, DIN 912/933/934, ISO 4014/4032, GB/T5783 | Global compliance |

| Thread Type | Metric, UNC, UNF | Coarse or fine thread |

| Head Types | Hex, socket, countersunk, pan, flange | Various designs available |

| Density | 4.51 g/cm³ | 45% lighter than steel |

| Tensile Strength | 550–1000 MPa | Depends on grade |

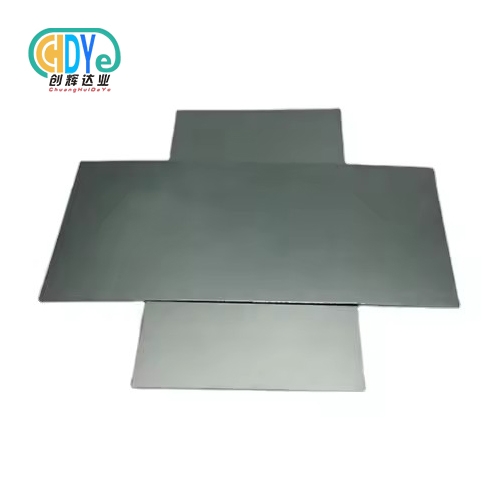

| Surface Finish | Polished, anodized, passivated | Optional colors available |

| Temperature Range | -250°C to +450°C | Excellent thermal stability |

Product Range

Our Titanium Fasteners line includes, but is not limited to:

- Titanium Bolts: Hex, socket, flange, and eye bolts.

- Titanium Nuts: Hex, lock, cap, and coupling nuts.

- Titanium Screws: Machine screws, self-tapping screws, and countersunk screws.

- Titanium Washers: Flat, spring, and conical washers.

- Threaded Rods & Studs: Custom cut-to-length options.

- Special Fasteners: OEM parts for aerospace, automotive, and chemical industries.

Our Products

Application Advantages

Titanium fasteners are widely used across multiple industries that demand corrosion resistance and high mechanical strength, including:

- Aerospace & Defense: Aircraft engines, airframes, and missile systems.

- Chemical Processing: Reactors, pressure vessels, and pipeline joints.

- Marine & Offshore: Ships, submarines, and desalination equipment.

- Automotive & Motorsport: Exhaust systems, suspension assemblies, and lightweight chassis.

- Medical Equipment: Orthopedic implants and precision surgical instruments.

- Energy & Power Plants: Heat exchangers, turbines, and environmental systems.

Be used in a wide range of industries.

Marine engineering

Medical implants

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

Shaanxi Chuanghui Daye is equipped with state-of-the-art facilities for titanium melting, forging, CNC machining, and threading.

Our production lines support:

- Cold and hot forging

- CNC precision machining (±0.02 mm tolerance)

- Heat treatment and surface finishing

- 100% thread gauge inspection

- Custom tool design for OEM parts

Our R&D department continues to develop innovative titanium fastening solutions for new energy, hydrogen systems, and high-temperature environments.

|

|

|

|

|

|

|

|

Surface Treatment & Mechanical Properties

| Property | Typical Value | Notes |

|---|---|---|

| Surface Roughness | Ra ≤ 0.8 μm | Mirror or matte finish |

| Hardness | HV 180–350 | Grade dependent |

| Yield Strength | 485–930 MPa | High mechanical reliability |

| Modulus of Elasticity | 105 GPa | Excellent flexibility |

| Coating Options | Anodized, PVD, or passivated | For enhanced corrosion protection |

All fasteners undergo anti-rust coating or vacuum packing to ensure surface integrity during long-term storage and transportation.

Quality Assurance

Quality is at the heart of every fastener we produce.

Shaanxi Chuanghui Daye operates under an ISO 9001:2015 certified quality management system to ensure full traceability and reliability.

Our quality inspection process includes:

- Raw material testing with spectrometer analysis

- Dimensional and mechanical property checks

- Ultrasonic and magnetic particle testing

- Visual and torque performance verification

- Third-party inspection available (SGS, BV, or TUV)

OEM & Customization Services

We provide OEM / ODM fastener customization to meet your exact application needs:

- Custom thread forms and non-standard dimensions

- Head designs (socket, torx, or 12-point)

- Special coatings or anodizing colors

- Small batch or prototype production

- Engineering consultation and CAD drawing review

Our team ensures technical precision and cost-effective production for every customized order.

Packaging & Global Logistics

To guarantee safe and secure delivery, we follow international export packaging standards:

- Inner Packaging: Vacuum-sealed or anti-rust film wrapping.

- Outer Packaging: High-strength wooden cases with foam cushioning.

- Labeling: Detailed product specifications, batch numbers, and inspection reports attached.

- Shipping Options: Air, sea, and land transportation available worldwide with full tracking.

Each shipment is protected against moisture, vibration, and mechanical impact to ensure product integrity upon arrival.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

Inspection Process

1. Appearance and dimension inspection to ensure every titanium tube meets tolerances,no cracks, pits or other defects on the surface.

2. 100% Straightness inspection.

3. 100% Hydro Testing.

4. Ultrasonic and eddy current testing make sure the product without cracks and scratch.

5. Testing Tensile strength, yield strength by our Tension Tester and the Third party lab to double check the quality.

Why Choose Us

- Over 30 years of experience in rare metal manufacturing

- Advanced melting, forging, and machining technology

- Reliable ISO 9001:2015 quality system

- Competitive pricing and 7-day rapid delivery for standard sizes

- Professional after-sales service and technical support

- Exported to over 50 countries including the USA, Germany, Japan, and the UAE

|

|

|

|

|

|

FAQs

Q1: Can titanium fasteners be used in seawater?

A1: Yes. Titanium fasteners are fully resistant to seawater corrosion and biofouling, making them ideal for marine applications.

Q2: Do you offer custom head or thread designs?

A2: Absolutely. Our CNC facility supports custom designs based on drawings or 3D models.

Q3: What is the maximum temperature titanium fasteners can withstand?

A3: They perform reliably up to 450°C depending on the alloy grade used.

Q4: How can I verify material authenticity?

A4: Every batch is supplied with a material test certificate (MTC) and chemical composition report.

Q5: Can I order small quantities for trial use?

A5: Yes, we welcome small-batch and prototype orders for testing and R&D applications.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email