- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

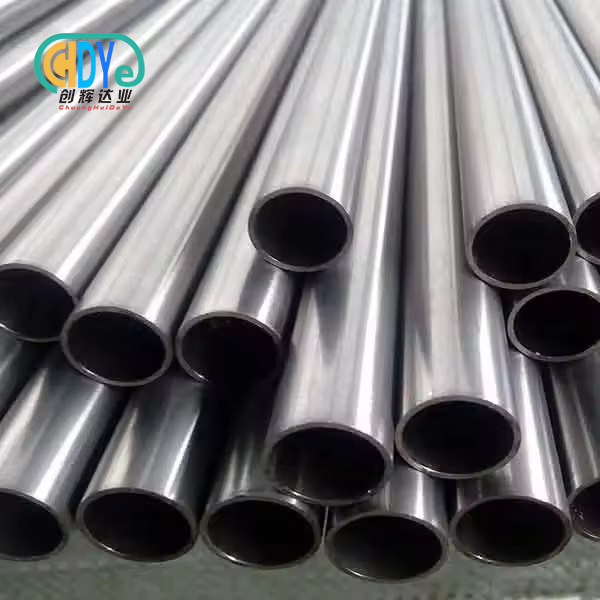

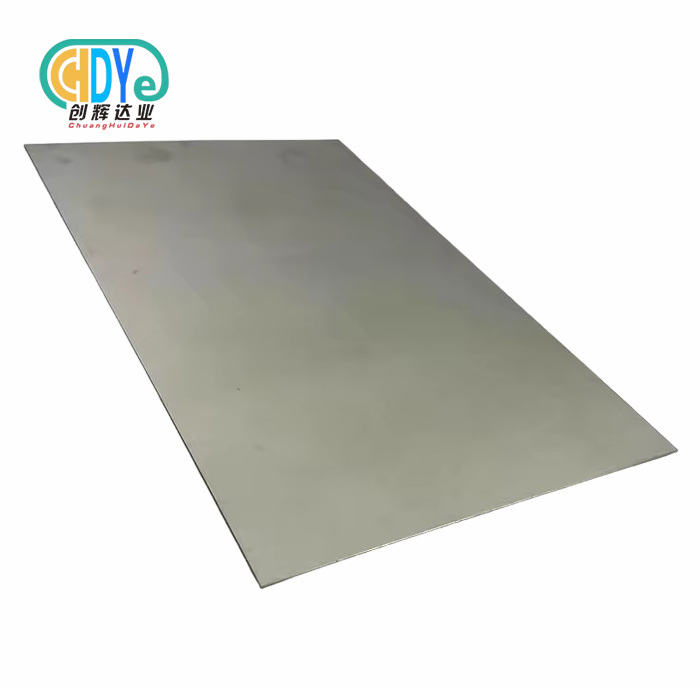

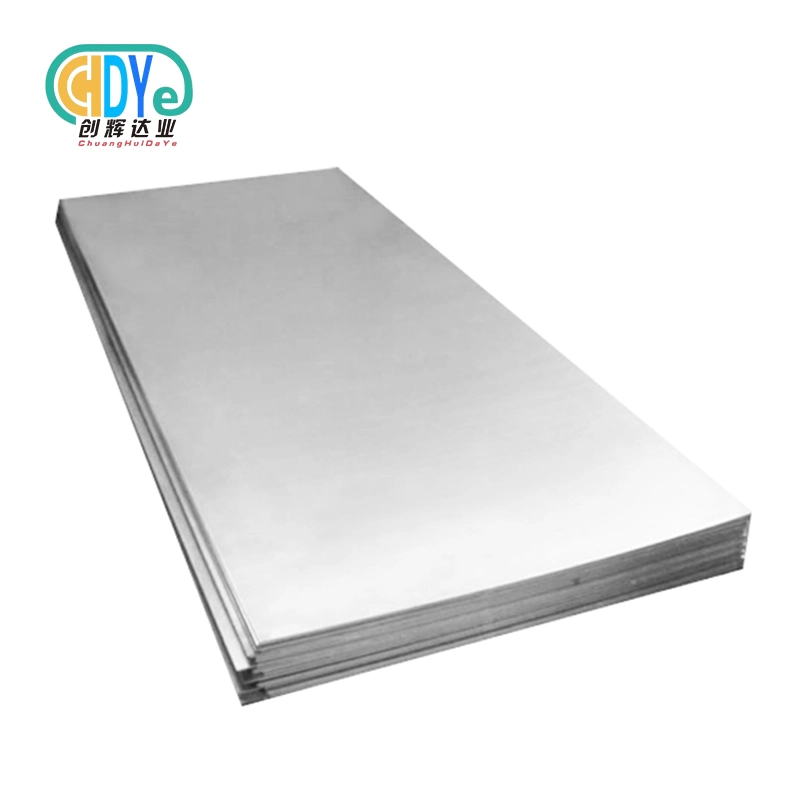

Pure Titanium Sheet

We have normal size in stock with quick delivery 1-5 days

Samples for testing are always available

Product Overview

Pure Titanium Sheet is made from commercially pure titanium (CP-Ti), offering superior corrosion resistance, excellent strength-to-weight ratio, and outstanding formability. It is designed for industrial, chemical, marine, and medical applications where durability, chemical stability, and precision are essential. Our sheets are suitable for large-scale fabrication, allowing cutting, welding, bending, and surface finishing to meet the requirements of batch production and customized projects.

Chdymetal is a global metal supplier of pure titanium sheet, we can provide various grade and type, As its unique combination of high strength, light weight, corrosion resistance, bio-compatibility, and higher temperature performance, Titanium sheet is widely used in aerospace, medical, industrial, and oil and gas industries.

Available Grade: GR1, GR2, GR3, GR4

we have normal size in stock with quick delivery 1-5 days

Samples for testing are always available

|

Product name |

Grade |

Specification(mm) |

|

Pure titanium sheet |

GR1 |

(0.3-80) ×Width ≤1220-2300 ×length≤2440-6500 |

|

GR2 |

(0.3-80) ×Width ≤1220-2300 ×length≤2440-6500 |

|

|

Standard |

ASTM B 265 |

|

|

Surface treatment |

Bright, Polished, Pickling, Sandblasting |

|

|

Processing method |

cold rolling / hot rolling |

|

|

Packing |

Moisture-proof cloth, foam cotton inside, wooden case outside. |

|

|

Payment terms |

T/T 30% deposit and 70% balance before shipment |

|

Pure titanium sheet Chemical composition:

|

Grade |

Ti |

Chemical composition (%) |

||||||

|

Impurity(%) Max |

Residual elements |

|||||||

|

Fe |

C |

N |

H |

O |

Single |

Total |

||

|

Gr1 |

Bal |

0.20 |

0.08 |

0.03 |

0.015 |

0.18 |

0.10 |

0.40 |

|

Gr2 |

Bal |

0.30 |

0.08 |

0.03 |

0.015 |

0.25 |

0.10 |

0.40 |

|

Gr3 |

Bal |

0.30 |

0.08 |

0.05 |

0.015 |

0.35 |

0.10 |

0.40 |

|

Gr4 |

Bal |

0.50 |

0.08 |

0.05 |

0.015 |

0.40 |

0.10 |

0.40 |

Pure titanium sheet Mechanical property:

|

Material |

Condition |

Thickness mm |

Mechanical Property |

||

|

Tensile strength Rm/Mpa |

Yield strength Rp0.2/Mpa |

Elongation A% |

|||

|

Gr1 |

M |

<25 |

Min 240 |

Min 170 Max 310 |

Min 24 |

|

Gr2 |

M |

<25 |

Min 345 |

Min 275 Max 450 |

Min 20 |

|

Gr3 |

M |

<25 |

Min 450 |

Min 380 Max 550 |

Min 18 |

|

Gr4 |

M |

<25 |

Min 550 |

Min 438 Max 660 |

Min 15 |

Key Features and Advantages

- Superior Corrosion Resistance: Resistant to seawater, chemicals, and oxidizing environments.

- Excellent Strength-to-Weight Ratio: Provides durability while reducing structural weight.

- High Formability: Easily cut, bent, welded, or stamped for industrial projects.

- Consistent Quality: Each batch undergoes rigorous inspection for thickness, flatness, and mechanical properties.

- Long Service Life: Maintains structural and chemical integrity under prolonged exposure.

- Batch Production Ready: Optimized for bulk orders and large-scale fabrication.

Manufacturing & Processing Capability

Our titanium sheets are produced using vacuum melting, forging, cold rolling, and precision surface finishing. Advanced equipment such as electron beam furnaces, CNC rolling machines, and annealing furnaces ensure uniform thickness, fine microstructure, and flat, smooth surfaces. Every sheet undergoes thorough inspection for mechanical properties, thickness, and surface quality.

|

|

|

|

|

|

|

|

Quality Assurance

- Material Verification: Chemical composition and mechanical testing for each batch.

- Non-Destructive Testing: Ultrasonic inspection ensures defect-free sheets.

- Traceability: Batch numbers, production dates, and Mill Test Reports are provided.

- ISO Certification: ISO 9001:2015 ensures international quality compliance.

- Consistent Batch Quality: Ideal for bulk buyers requiring repeatable material performance.

Application Advantages

- Chemical Industry: Storage tanks, piping, heat exchangers, and reactors.

- Marine Engineering: Hulls, decks, offshore platforms, and desalination equipment.

- Aerospace Components: Structural panels, brackets, and reinforcement elements.

- Medical Devices: Surgical instruments, implants, laboratory apparatus.

- Energy & Environmental Systems: Condensers, pipelines, chemical process machinery.

- Electronics Industry: Precision parts for high-purity or semiconductor applications.

Be used in a wide range of industries.

Marine engineering

Medical implants

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

R&D and Customization

Our R&D team focuses on industrially practical improvements:

- High Purity & Low Impurities: Optimized for corrosion resistance and ductility.

- Surface and Flatness Enhancements: Polishing, brushing, and pickling to reduce defects.

- Thickness Consistency: Precision cold-rolling and annealing processes.

- Prototype & Batch Testing: Ensures performance consistency for large orders.

- Technical Support: Assistance in welding, bending, stamping, and custom fabrication for bulk buyers.

Packaging & Logistics

Sheets are packed with anti-rust film, foam protection, and export-standard wooden crates. Clear labels with material grade, dimensions, and batch numbers are provided. Transportation options include air, sea, and land shipping for safe, timely delivery.

|

|

|

|

|

|

|

|

|

|

|

|

OEM & Customization Services

We provide:

- Custom thickness, width, and length for bulk orders

- Specific surface treatments and mechanical properties

- Prototype and small-batch production for large-scale projects

- Technical consultation for fabrication, welding, and assembly

Global Market & Cooperation

Pure Titanium Sheets are exported to over 50 countries including the USA, Germany, France, Mexico, South Korea, and Singapore. We work closely with distributors, manufacturers, and industrial end-users, offering reliable supply, technical support, and long-term partnerships.

Feedback from customers

Why Choose Us :

1.Rich experience in metal industry and we can give you professional advice when you select the suitable material.

2.Chdymetal can cut to precise dimensions with very tight tolerances. Rather than ordering big titanium plate and cutting the material yourself, let us do the cutting for you and reduce your risk and scrap.

3.Stock products with various grade and size, we can arrange quick delivery on the same day.

Just feel free to contact us with your detailed requirements, we will back to you with a quotation.

|

|

|

|

|

|

Pure Titanium Sheet Transaction Process

1.Appearance and dimension inspection to ensure every titanium rod meets tolerances.

2. Ultrasonic and eddy current testing make sure the product without cracks and scratch.

3.100% Straightness inspection.

Testing Tensile strength, yield strength by our Tension Tester and the Third party lab to double check the quality.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Chdymetal have more than 30year's experience in Non-ferrous metal industry, Pure Titanium Sheet is one of our main products, we have common size in stock all year round and we can arrange 1-3days quick delivery.

Welcome to contact us for more information: info@chdymetal.com/ Mob.: 86-18049386902

Learn about our latest products and discounts through SMS or email