- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

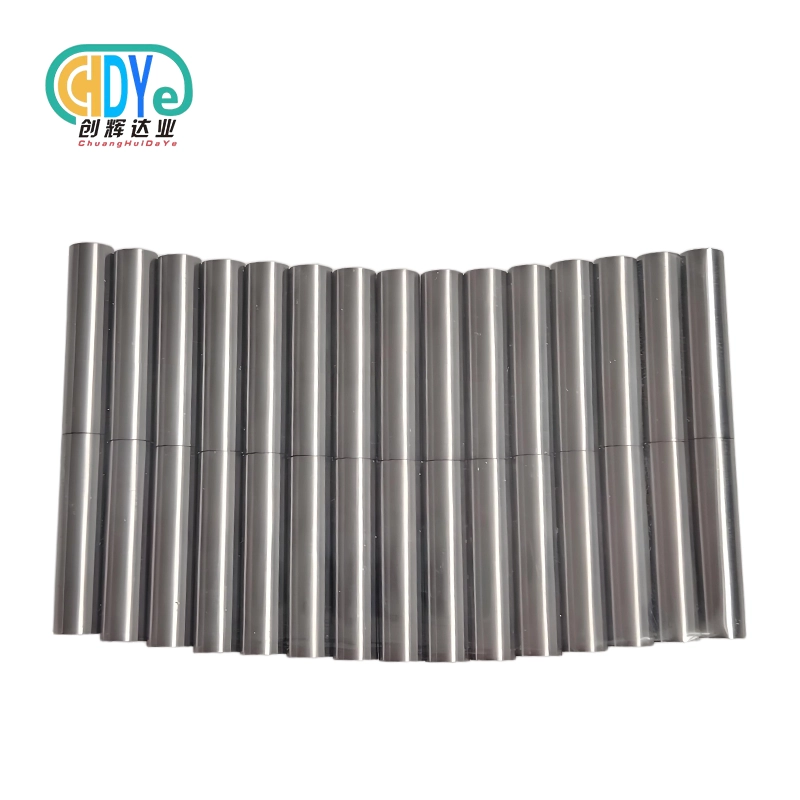

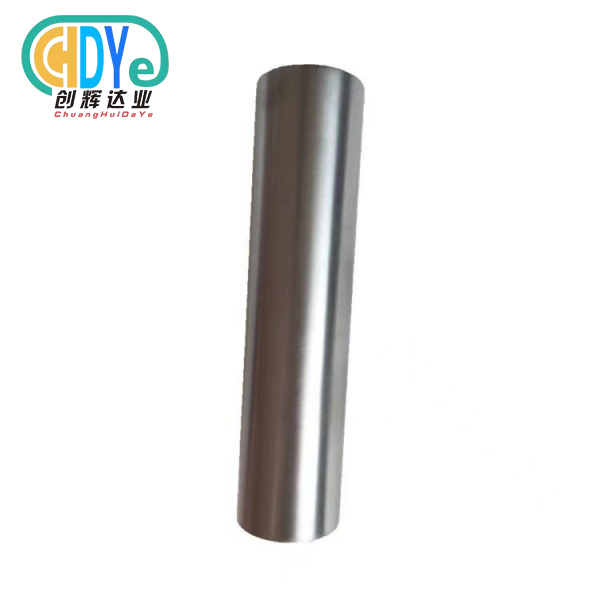

Gr2 Titanium Coil

2.Type:Coils, Foils, Rolls, Plain Sheet,Strip

Product Overview

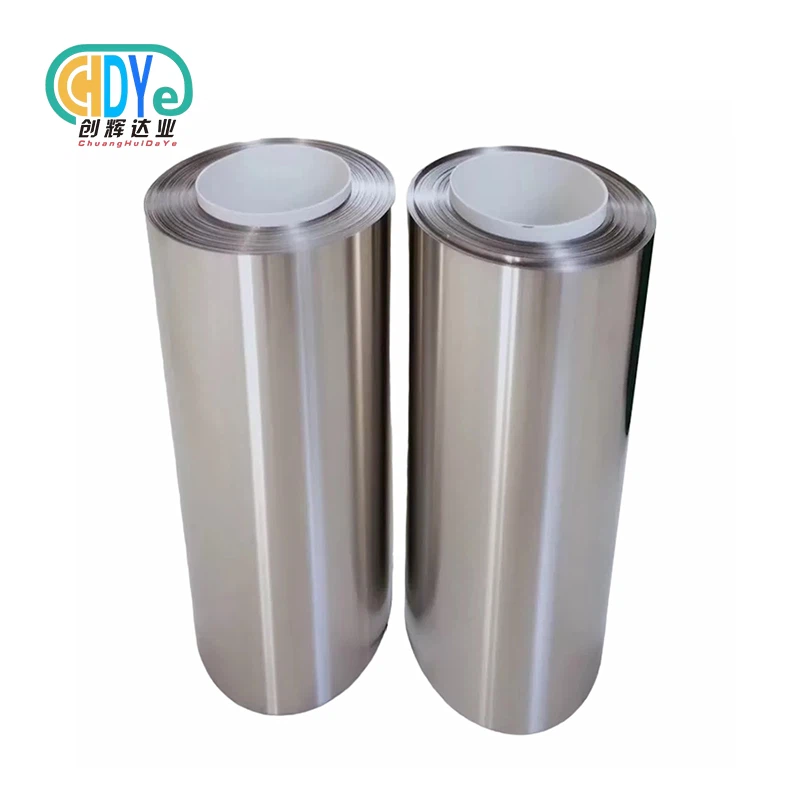

Gr2 Titanium Coil is a high-performance, commercially pure titanium product with excellent corrosion resistance, high strength-to-weight ratio, and outstanding formability. It is typically supplied in continuous rolled form and is ideal for applications that require flexible, weldable, and lightweight titanium materials. The coil format makes it especially suitable for automated fabrication, continuous processing, and high-volume production environments.

Gr2 Titanium coil are mainly used for the manufacture of welded titanium tubes, which are further extensively used for heat exchangers, condensers, coolers and evaporators in coastal power plants, seawater desalination systems, offshore drilling platforms, and petroleum refineries.

|

Standard |

ASTM / ASME SB265 |

|

Size |

1000 mm x 2000 mm, 1220 mm x 2440 mm, 1220*Length |

|

Thickness |

1mm to 12 mm Thk |

|

Type |

Coils, Foils, Rolls, Plain Sheet, Strip, |

|

Finish |

Hot rolled plate (HR), Cold rolled sheet (CR) |

|

Hardness |

Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. |

|

Packing Detail |

Standard export package:Wooden pallet +paperboard +coil |

|

Delivery time |

1.Usually,within10-20days after receiving deposit |

Product Features and Benefits

- Superior Corrosion Resistance: Performs exceptionally in oxidizing and chloride-containing environments.

- Flexible Coil Design: Easy for continuous forming, welding, and cutting processes.

- Excellent Mechanical Stability: Maintains strength even at elevated temperatures.

- Precision Thickness Control: Ensures consistent material performance throughout the coil.

- Clean and Oxide-Free Surface: Ideal for chemical and medical-grade applications.

- Cost Efficiency for Bulk Production: Continuous rolling allows optimized material utilization.

Material Testing:

Every batch of order we provide material certificate to our customer, details conclude below:

• Mechanical Testing Such as Tensile of Area

• Hardness Test

• Chemical Analysis

Production process: Titanium coils and strips are made from high-quality sponge titanium as raw material, through processes such as ingot melting, forging, hot rolling, cold rolling, annealing, and curling. These processes ensure the high quality and stability of titanium coils and tapes

Manufacturing & Processing Capability

Shaanxi Chuanghui Daye Metal Material Co., Ltd. utilizes advanced rolling, annealing, and straightening equipment to produce Gr2 Titanium Coil with consistent quality and high accuracy. Our facilities are equipped with:

- Precision cold-rolling mills for thickness control within ±0.01 mm

- Vacuum annealing furnaces to eliminate stress and oxide layers

- Automatic slitting lines for precise width cutting

- Surface polishing machines for enhanced brightness and cleanliness

- Ultrasonic and eddy current inspection systems for defect detection

|

|

|

|

|

|

|

|

Quality Assurance

Each Gr2 Titanium Coil undergoes a full range of inspections before shipment:

- Chemical composition analysis by spectrometer

- Mechanical performance tests (tensile, elongation, hardness)

- Ultrasonic and surface flaw inspection

- Dimensional tolerance and flatness check

- Cleanliness and oxide layer assessment

All quality processes are carried out under the ISO 9001:2015 certified management system to guarantee product traceability and reliability.

Application Advantages

- Chemical Processing Equipment: Heat exchangers, reactors, and piping systems.

- Aerospace and Marine Engineering: Lightweight corrosion-resistant cladding materials.

- Electronics and Energy Storage: Battery shells and shielding structures.

- Medical and Pharmaceutical Industry: Equipment requiring biocompatible titanium.

- Automotive Manufacturing: Exhaust components, heat shields, and catalytic converters.

- Industrial Fabrication: Used in stamping, forming, and continuous assembly operations.

Be used in a wide range of industries.

Marine engineering

Medical implants

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

R&D and Customization

Our R&D team continuously improves titanium coil manufacturing technology by optimizing cold rolling tension, annealing atmosphere, and surface treatment parameters. We collaborate with material research institutes to develop:

- High-uniformity thin coils for precision forming

- Enhanced corrosion-resistant alloys for marine applications

- Improved mechanical properties through microstructure refinement

- Customized foil-to-coil integration solutions for automated lines

These ongoing innovations help wholesalers and manufacturers reduce material waste, improve processing efficiency, and enhance product reliability.

Packaging & Logistics

Gr2 Titanium Coils are vacuum-sealed, wrapped in anti-rust paper, and secured with foam and wooden crates. Each coil is labeled with grade, size, and heat number for full traceability. We cooperate with major international freight companies to ensure on-time global delivery.

|

|

|

|

|

|

|

|

|

|

|

|

OEM & Customization Services

- Custom coil width, thickness, and ID/OD dimensions

- Surface polishing, annealing, and coating treatments

- Coil slitting and rewinding per customer’s processing line

- Long-term supply contracts for distributors and fabricators

- Material certification and third-party inspection upon request

Global Market & Cooperation

Our Gr2 Titanium Coil products are exported to over 45 countries, serving large-scale buyers in industries such as aerospace, electronics, and energy. We offer stable supply capacity, fast delivery, and flexible OEM cooperation to help global distributors expand their titanium material business.

Feedback from customers

Why Choose Us :

1. You can get the perfect material according to your requirement at the least possible price.

2. We offer FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

3. The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

4. You can get stock alternatives, mill deliveries with minimizing manufacturing time.

5. We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

Sample order is supported!

|

|

|

|

|

|

Gr2 Titanium Coil Transaction Process

1.First contact us to provide the grade, size ,quantity and standard or any special requirements.

2.we will reply you the quotation with delivery time in 3 hours.

3.reach an agreement then buyer arrange the prepayment.

4. when we get your payment we will arrange production asap and share you the production progress.

5.when production finished, will give buyer the actual weight of the products, then the buyer arrange balance payment.

6. Arrange shipment according to the most economical form we have agreed on

7.Meanwhile send buyer the material certificate.

8. Regular after-sales service to know the actual product usage.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Chdymetal have more than 30year's experience in Non-ferrous metal industry, Gr2 Titanium Coil is one of our main products, we have common size in stock all year round and we can arrange 1-3days quick delivery.

Welcome to contact us for more information: info@chdymetal.com/ Mob.: 86-18049386902

Learn about our latest products and discounts through SMS or email