- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

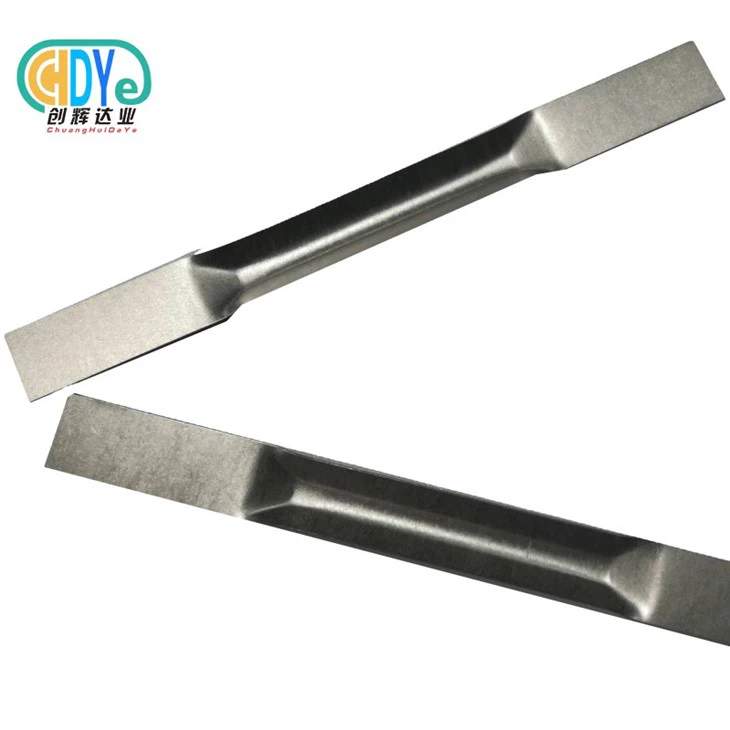

pure niobium metal round bar

2. Grade:RO4200, RO4210

3. Purity: 99.99%

4.Size: Customized

Product Production

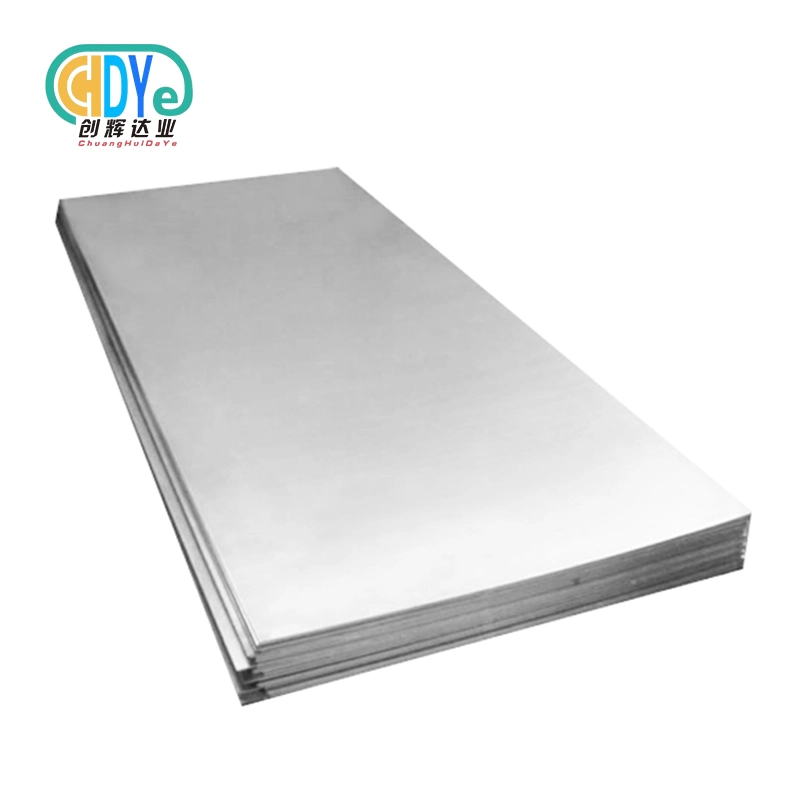

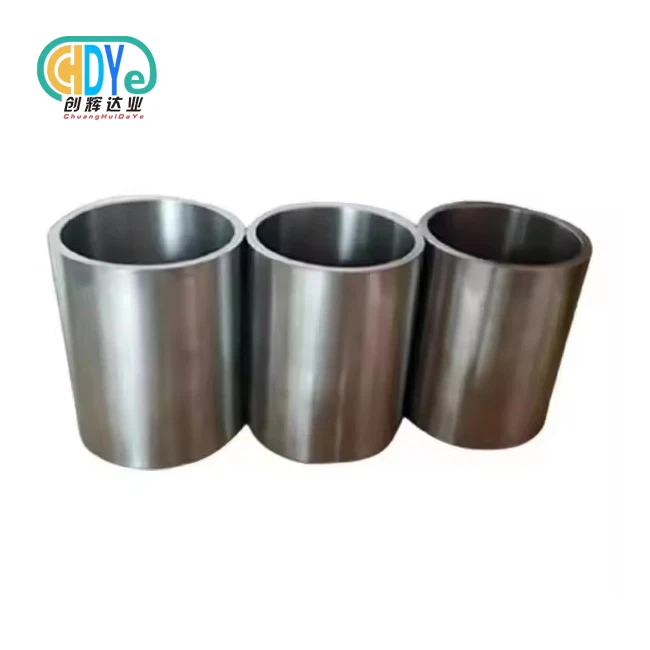

When you need exceptional corrosion resistance and biocompatibility for your most demanding applications, our pure niobium metal round bar delivers unmatched performance. Manufactured to the highest industry standards, these precision-engineered bars offer superior mechanical properties and chemical stability. Our niobium round bars are crafted from 99.9% pure niobium, ensuring optimal performance in electronics, medical devices, and specialized industrial applications.

Key Features and Benefits

Our niobium round bars stand out in the marketplace for several compelling reasons. You get exceptional corrosion resistance that outperforms many other metals in harsh chemical environments. The biocompatible nature makes these bars perfect for medical implants and surgical instruments.

High-temperature stability ensures reliable performance even under extreme thermal conditions. The excellent machinability allows for precise fabrication and custom modifications. Additionally, the superior electrical conductivity makes these bars ideal for electronic components and superconducting applications.

Technical Specifications

| Property | Specification |

|---|---|

| Purity | Nb ≥99.9% |

| Diameter Range | 3-350 mm |

| Length | As customer's requirements |

| Density | 8.57 g/cm³ |

| Tensile Strength | 200-350 MPa |

| Melting Point | 2468°C |

| Surface Finish | Polished/As-rolled |

| Hardness | 70-90 HV |

| Certificate | ISO 9001:2015 |

| Condition | Annealed |

| Product Features |

Excellent Corrosion Resistance Good resistance to effect of heat |

| Delivery time | Normal production time need about 10-15 days |

| Payment terms | 30%TT inadvance, 70% balance before shipment |

Available Grades and Materials

We offer various grades to meet your specific requirements. Commercial pure niobium provides excellent corrosion resistance for general applications. High-purity grades are available for semiconductor and research applications. Custom alloy compositions can be produced upon request.

Each grade maintains strict chemical composition control. Our quality team ensures consistent mechanical properties across all batches. Material certificates accompany every shipment for complete traceability.

|

Material |

Main elements(%) |

Impurities (Maximum %) |

||||||||||

|

Nb |

Fe |

Si |

Ni |

W |

Mo |

Ti |

Ta |

O |

C |

H |

N |

|

|

RO4200 |

Remainder |

0.004 |

0.004 |

0.002 |

0.005 |

0.005 |

0.002 |

0.07 |

0.015 |

0.0040 |

0.0015 |

0.003 |

|

RO4210 |

Remainder |

0.01 |

0.01 |

0.005 |

0.02 |

0.01 |

0.004 |

0.10 |

0.02 |

0.01 |

0.0015 |

0.01 |

Manufacturing Process

Our manufacturing process begins with high-quality niobium raw materials sourced from trusted suppliers. The materials undergo vacuum arc melting to achieve exceptional purity levels. Precision forging and rolling operations create the desired dimensions and surface finish.

Heat treatment processes optimize the microstructure for enhanced performance. Final machining operations ensure tight dimensional tolerances. Quality control inspections verify compliance with your specifications at every stage.

|

|

|

|

|

|

|

|

Applications and Industries

Electronics manufacturers rely on our pure niobium metal round bar for superconducting components and electronic devices. The medical industry uses these bars for surgical implants, pacemaker components, and dental applications due to their biocompatibility.

Aerospace companies specify niobium for jet engine components and rocket nozzles. Chemical processing plants utilize the excellent corrosion resistance for reactor components. Research institutions depend on our high-purity materials for laboratory equipment and experimental setups.

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

Standard diameter tolerances range from ±0.1mm to ±0.5mm depending on size. Length tolerances are maintained at ±5mm for standard products. Custom tolerances can be achieved through precision machining operations.

Straightness specifications meet or exceed industry standards. Surface finish requirements are customizable based on your application needs. All dimensional specifications are verified through comprehensive inspection procedures.

Product Features in Detail

The crystalline structure of our niobium bars provides exceptional ductility and formability. This allows for complex forming operations without cracking or material failure. The low work hardening rate enables extensive cold working capabilities.

Thermal expansion characteristics remain stable across wide temperature ranges. The material exhibits excellent fatigue resistance under cyclic loading conditions. Weldability is superior when proper techniques and atmospheres are employed.

Quality Assurance and Testing

Every batch undergoes rigorous chemical analysis to verify composition. Mechanical testing confirms tensile strength, yield strength, and elongation properties. Ultrasonic inspection detects any internal defects or discontinuities.

Surface quality inspection ensures smooth, defect-free finishes. Dimensional verification confirms compliance with specified tolerances. Documentation packages provide complete material traceability and certification.

|

|

|

OEM & Customization Services

Our experienced engineering team works closely with you to develop custom solutions. We can modify dimensions, surface treatments, and mechanical properties to meet specific requirements. Prototype development services help validate designs before full production.

Small quantity orders receive the same attention to quality as large production runs. Technical support continues throughout the product development process. Our flexibility allows for rapid response to changing requirements.

Packaging and Shipping

Products are carefully packaged to prevent damage during transit. Protective materials safeguard surface finishes and dimensional accuracy. Proper labeling ensures easy identification and handling.

International shipping capabilities reach customers worldwide. Express delivery options are available for urgent requirements. Tracking information keeps you informed throughout the shipping process.

|

|

|

|

|

|

|

|

|

Why Choose Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd. brings over 30 years of rare metal expertise to every project. Located in China's "Titanium Capital," we have access to premium raw materials and advanced manufacturing facilities.

Our commitment to quality ensures consistent, reliable products that meet your exact specifications. Competitive pricing and on-time delivery help you maintain project schedules and budgets. When you choose our pure niobium metal round bar, you partner with a trusted supplier focused on your success.

|

|

|

|

|

|

FAQs

Q: What is the minimum order quantity?

A: We accommodate both small prototype quantities and large production orders based on your needs.

Q: Can you provide material certificates?

A: Yes, complete material certificates with chemical and mechanical test results accompany every shipment.

Q: What surface finishes are available?

A: We offer polished, as-rolled, and custom surface finishes to meet your application requirements.

Q: How do you ensure product quality?

A: Comprehensive testing including chemical analysis, mechanical testing, and dimensional inspection ensures consistent quality.

Contact Us

Ready to experience the superior performance of our pure niobium metal round bar? Our technical team is standing by to discuss your specific requirements and provide detailed quotations.

Contact us today at info@chdymetal.com or reach out to our sales team for immediate assistance. We look forward to becoming your trusted partner for premium niobium products and exceptional service.

Learn about our latest products and discounts through SMS or email