- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

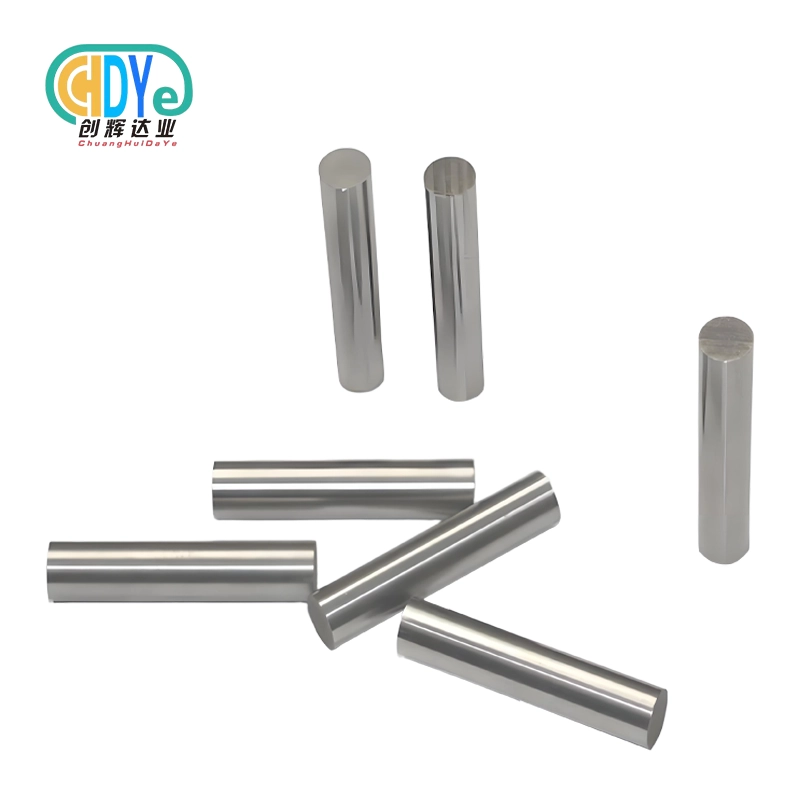

tantalum alloy seamless tube

2. Applications: Used in heat exchange tubes of heat exchangers.

3. Standard : As per ASTM B521-98

Product Introduction

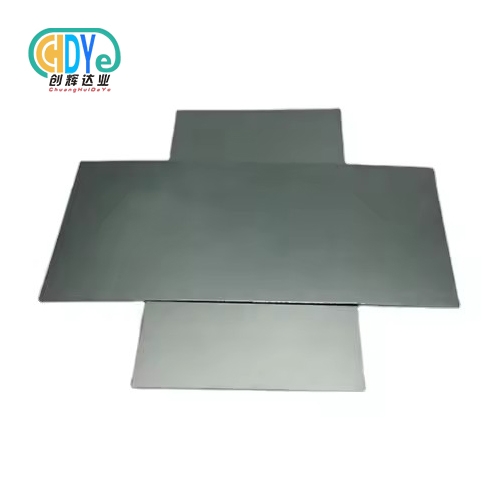

Tantalum has the characteristics of a high melting point, corrosion resistance, and good cold-working performance. Tantalum tubes are mostly used in the semiconductor industry, high-temperature materials, anti-corrosion industry, electronics industry, etc., such as tantalum reaction vessels, tantalum heat exchangers, tantalum thermocouple protection tubes, etc.Chdymetal provide tantalum alloy seamless tubes in R05200, R05400, R05252(Ta-2.5W), and R05255(Ta-10W) materials, the product surface is smooth and scratch-free, which meets the ASTM B521 standard.

Key Features and Benefits

- Superior Corrosion Resistance: Exceptional resistance to most chemicals and acids

- High-Temperature Performance: Maintains stability at temperatures up to 302°F (159°C)

- Seamless Construction: No welded joints means enhanced structural integrity

- Excellent Ductility: Easy to work with for complex applications

- Chemical Stability: Forms protective oxide layer naturally

- Long Service Life: Minimal maintenance requirements

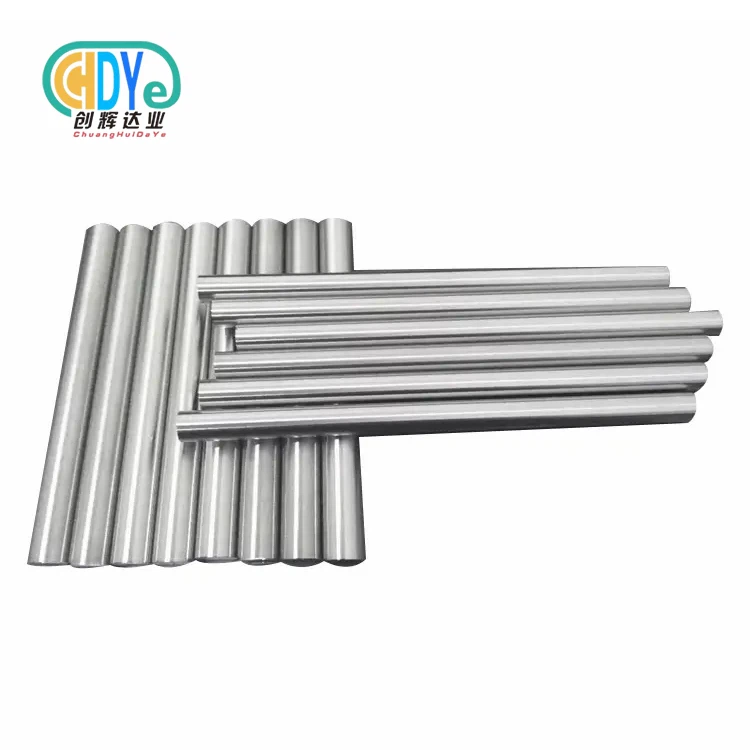

Technical Specifications

| Specification | Range/Value |

|---|---|

| Outer Diameter | 5-100 mm |

| Wall Thickness | 0.5-20 mm |

| Length | Up to 3000 mm |

| Density | 16.7-17 g/cm³ |

| Melting Point | 5,463°F (2,996°C) |

| Purity | 99.95% (metallic purity without Nb) |

| Surface Finish | Smooth, oxide-free |

| Standard | ASTM B521 |

| Production time | Stock size is 1-5days, normal production time 15-20 days |

| Payment term | 30%TT in advance, 70% before shipment |

Chemical composition

|

Content, Max, Weight % |

||||

|

Element |

R05200 Uanlloyed Tantalum |

R05255 90% Tantalum 10% Tungsten |

R05252 97.5% Tantalum 2.5% Tungsten |

R05240 60% Tantalum 40% Niobium |

|

C |

0.010 |

0.010 |

0.010 |

0.010 |

|

O |

0.015 |

0.015 |

0.015 |

0.020 |

|

N |

0.010 |

0.010 |

0.010 |

0.010 |

|

H |

0.0015 |

0.0015 |

0.0015 |

0.0015 |

|

Fe |

0.010 |

0.010 |

0.010 |

0.010 |

|

Mo |

0.020 |

0.020 |

0.020 |

0.020 |

|

Nb |

0.100 |

0.100 |

0.50 |

35.0~42.0 |

|

Ni |

0.010 |

0.010 |

0.010 |

0.010 |

|

Si |

0.005 |

0.005 |

0.005 |

0.005 |

|

Ti |

0.010 |

0.010 |

0.010 |

0.010 |

|

W |

0.05 |

9.1~11.0 |

2.0~3.5 |

0.050 |

|

Ta |

Remainder |

Remainder |

Remainder |

Remainder |

|

Mechanical Property |

Grade |

Tensile strength min |

Yield strength min, |

Elongation min,% |

|

Pure Ta(R05200 R05400) |

30000(207) |

20000(138) |

20 |

|

|

Ta-10W(R05255) |

70000(482) |

60000(414) |

15 |

|

|

Ta-2.5W(R05252) |

40000(276) |

30000(207) |

20 |

|

|

Ta-40Nb(R05240) |

35000(241) |

20000(138) |

25 |

Available Grades and Materials

We offer various tantalum alloy compositions to meet specific application requirements:

- Ta-Nb Alloys: Enhanced mechanical properties with niobium addition

- Ta-W Alloys: Improved strength and temperature resistance with tungsten

- R05252: 97.5% tantalum, 2.5% tungsten alloy

- R05255: 90% tantalum, 10% tungsten alloy

- Custom Compositions: Tailored alloys for specific applications

Manufacturing Process

Our seamless tubes undergo rigorous manufacturing steps:

- Raw Material Selection: High-purity tantalum and alloying elements

- Melting Process: Electron-beam furnace or vacuum-arc melting

- Extrusion: Seamless tube formation from solid billets

- Cold Working: Precise dimensional control and surface finish

- Heat Treatment: Stress relief and property optimization

- Quality Control: Comprehensive testing and inspection

|

|

|

|

|

|

|

|

Applications and Industries

Our tantalum alloy seamless tube finds applications across diverse industries:

- Aerospace: Engine components and structural elements

- Chemical Processing: Reactor vessels and heat exchangers

- Medical Devices: Biocompatible implants and surgical instruments

- Electronics: High-performance capacitors and components

- Nuclear Industry: Corrosion-resistant piping systems

- Research Facilities: Laboratory equipment and experimental setups

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

We maintain strict dimensional tolerances to ensure consistent quality:

- Outer Diameter Tolerance: ±0.1 mm

- Wall Thickness Tolerance: ±10%

- Length Tolerance: ±5 mm

- Straightness: Maximum 1 mm per meter

- Surface Roughness: Ra ≤ 1.6 μm

Product Features in Detail

The seamless construction of our tubes eliminates welded seams that could become failure points. Unlike welded alternatives, these tubes offer uniform wall thickness and consistent mechanical properties throughout their length. The natural oxide layer formation provides self-healing corrosion protection, making them ideal for harsh environments.

Quality Assurance and Testing

Every tube undergoes comprehensive quality testing:

- Chemical composition analysis

- Dimensional verification

- Surface quality inspection

- Mechanical property testing

- Pressure testing capabilities

- Non-destructive testing when required

|

|

|

OEM & Customization Services

We understand that each application has unique requirements. Our experienced team works closely with you to develop customized solutions. Whether you need specific dimensions, special alloy compositions, or unique surface treatments, we can accommodate your needs.

Packaging and Shipping

Your tubes are carefully packaged to prevent damage during transit:

- Individual protective wrapping

- Cushioned shipping containers

- Clear labeling and documentation

- International shipping capabilities

- Tracking information provided

|

|

|

Why Choose Us

With over three decades of experience in rare metal manufacturing, we bring unmatched expertise to every project. Located in China's "Titanium Capital," we combine traditional craftsmanship with modern technology. Our products serve customers in over 50 countries, demonstrating our commitment to quality and reliability.

We focus on competitive pricing, on-time delivery, and customer-focused service. Our team understands the critical nature of your applications and works diligently to exceed your expectations.

|

|

|

|

|

|

FAQs

Q: What's the difference between seamless and welded tubes?

A: Seamless tubes have no welded joints, offering superior structural integrity and pressure resistance. They're manufactured through extrusion rather than welding processes.

Q: Can you provide small quantities for testing ?

A: Yes, we accommodate both small testing orders and large production runs.

Q: What certifications do you provide?

A: We provide material certifications, dimensional reports, and chemical analysis certificates with each shipment.

Q: How do I maintain these tubes?

A: Our tantalum alloy seamless tube products require minimal maintenance. Simple cleaning with mild soap and water is usually sufficient.

Contact Us

Ready to discuss your tantalum alloy tube requirements? Our technical team is here to help you select the perfect solution for your application. Contact us today to get started with your project. We look forward to becoming your trusted partner in advanced metal solutions.

E-mail: info@chdymetal.com

Mob./What'spp: 86-18049386902

Learn about our latest products and discounts through SMS or email