- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

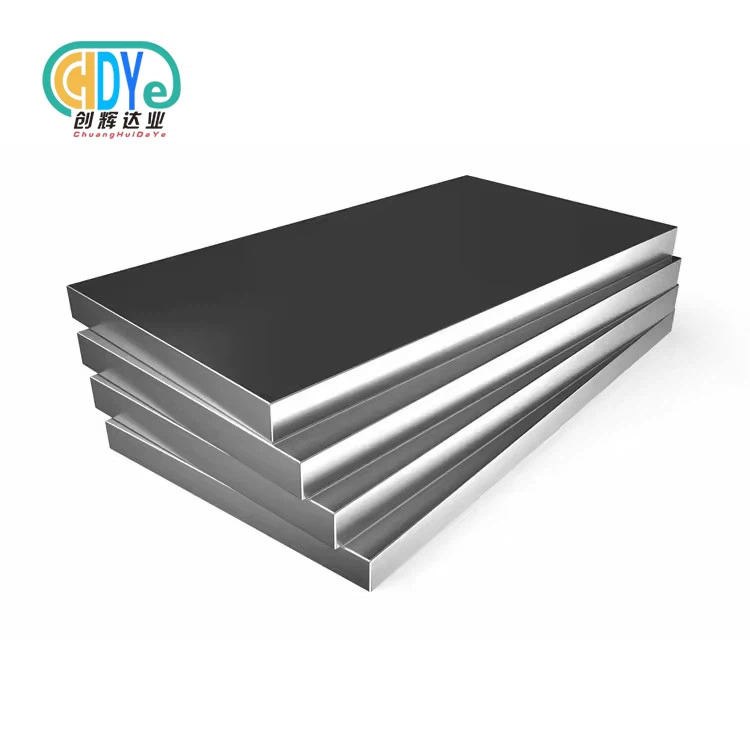

titanium sheet grade 2

2. Size: Thickness :0.5mm~50mm*Width:1000-3000mm

3. Standard: ASTM B265/ASME SB265, ASTMF67, ASTM F136

4. Type: plate, sheet, foil, strip

5. Surface: Bright, Polished, Pickling, Sandblasting 7. Processing method: cold rolling / hot rolling

Looking for reliable titanium sheet grade 2 for your industrial applications? You've found the right partner. Our premium Grade 2 titanium sheets offer the perfect balance of strength, formability, and corrosion resistance. As commercially pure titanium with 99.2% titanium content, these sheets deliver exceptional performance across diverse industries. With over 30 years of experience in rare metal manufacturing, we provide superior quality products that meet your exact specifications.

Key Features and Benefits

Our Grade 2 titanium sheets stand out for their remarkable versatility and performance. You get excellent corrosion resistance that outperforms stainless steel in harsh environments. The lightweight nature reduces overall weight by 40% compared to steel alternatives.

Superior formability allows easy welding, bending, and machining operations. The biocompatible properties make it safe for medical applications. Temperature resistance handles extreme conditions from cryogenic to 300°C. Non-magnetic characteristics suit electronic and precision applications perfectly.

Technical Specifications

|

Standard |

ASTM B265/ASME SB265, ASTMF67, ASTM F136 |

|

Grade |

GR1-GR5, GR7, GR9, GR11, GR12, TI-6AL-4V ELi |

|

thickness |

≤0.5mm-20mm |

|

Width |

≤2000mm |

|

Length |

1000mm-12000mm and customized |

|

Technique |

Cold rolling & Hot Rolling |

|

Surface |

Bright, Polished, Pickling, Sandblasting |

|

Shape |

Rectangular/Square/small pieces |

|

Application |

Metallurgy, electronics, medical, chemical, petroleum, pharmaceutical, aerospace, etc. |

| Package Terms | Moisture-proof cloth, foam cotton inside, wooden case outside. |

| Paymnt term | 30%TT in advance, 70% TTbalance before shipping |

Chemical composition

|

Grade |

Status |

Tensile Strength |

Yield Strength |

Elongation |

Area of Reducation |

||

|

Ksi |

Mpa |

Ksi |

Mpa |

% |

|||

|

≥ |

|||||||

|

GR1 |

Annealed |

35 |

240 |

25 |

170 |

24 |

30 |

|

GR2 |

50 |

345 |

40 |

275 |

20 |

30 |

|

|

GR3 |

65 |

450 |

55 |

380 |

18 |

30 |

|

|

GR4 |

80 |

550 |

70 |

483 |

15 |

25 |

|

|

GR5 |

130 |

895 |

120 |

828 |

10 |

25 |

|

|

TI-6AL-4VELI |

125 |

860 |

115 |

795 |

10 |

25 |

|

|

GR6 |

120 |

828 |

115 |

483 |

15 |

25 |

|

|

GR7 |

50 |

345 |

40 |

275 |

20 |

30 |

|

|

GR9 |

90 |

620 |

70 |

483 |

15 |

25 |

|

|

GR11 |

35 |

240 |

25 |

170 |

24 |

30 |

|

|

GR12 |

70 |

483 |

50 |

345 |

18 |

|

|

Available Grades and Materials

We specialize in commercially pure titanium offerings. Our primary focus is Grade 2 titanium, the most versatile and widely used grade. We also stock Grade 1 for maximum formability requirements and Grade 5 for higher strength applications.

All materials comply with ASTM B265, ASME SB265, and AMS specifications. Chemical composition meets strict industry standards with controlled oxygen, iron, and carbon content.

Manufacturing Process

Our advanced manufacturing starts with premium titanium sponge. Hot rolling creates the initial sheet thickness. Cold rolling achieves precise dimensions and surface finish. Annealing optimizes mechanical properties and relieves stress.

Quality control happens at every stage. Surface treatment removes scale and contaminants. Final inspection ensures dimensional accuracy and surface quality. Each batch receives complete traceability documentation.

Applications and Industries

Aerospace Industry: Aircraft components, engine parts, structural elements, and heat shields benefit from the lightweight strength.

Medical Sector: Surgical instruments, implants, and prosthetics utilize the biocompatible properties.

Chemical Processing: Heat exchangers, reaction vessels, and piping systems resist aggressive chemicals.

Marine Applications: Offshore equipment, desalination plants, and ship components withstand saltwater corrosion.

Automotive: Performance parts, exhaust systems, and racing components reduce weight while maintaining strength.

Be used in a wide range of industries.

Metallurgy and Special Steel

Electronics and Semiconductors

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

Thickness Range: 0.5mm to 50mm

Width Options: Up to 1500mm

Length: Up to 6000mm or coil form

Thickness Tolerance: ±0.05mm for thin sheets, ±0.1mm for thick plates

Surface Finish: Hot rolled, cold rolled, or polished options

Custom dimensions available upon request. We maintain extensive inventory for quick delivery of standard sizes.

Product Features in Detail

The titanium sheet grade 2 offers exceptional forming capabilities. You can easily stamp, draw, and bend these sheets without cracking. Welding characteristics are excellent with proper techniques and shielding gases.

Machining requires specific tooling and cutting parameters. The work-hardening tendency demands sharp tools and proper speeds. Surface treatments like anodizing and plating adhere well to the clean titanium surface.

Quality Assurance and Testing

Every shipment includes mill test certificates with complete chemical analysis. Mechanical testing verifies tensile strength, yield strength, and elongation values. Ultrasonic testing detects internal flaws in thicker sections.

Surface inspection ensures defect-free delivery. Dimensional verification confirms tolerance compliance. Our quality system follows ISO 9001 standards with continuous improvement protocols.

|

|

|

OEM & Customization Services

We understand your unique requirements need tailored solutions. Our engineering team works closely with you to develop custom specifications. Precision cutting services include waterjet, laser, and shear cutting options.

Special surface treatments and edge preparations are available. Prototype quantities help validate designs before full production. Technical support assists with material selection and application guidance.

Packaging and Shipping

Protective packaging prevents damage during transit. Wooden crates or steel cases protect larger sheets. Interleaving paper prevents surface scratching. Moisture barriers maintain product integrity.

Shipping options include air freight for urgent requirements and sea freight for economical delivery. Our logistics team coordinates worldwide shipping to over 50 countries. Tracking information keeps you informed throughout delivery.

|

|

|

|

|

|

|

|

|

Why Choose Us

Located in China's "Titanium Capital," we have direct access to premium raw materials. Three decades of industry experience ensures reliable quality and service. Our founder's expertise guides continuous improvement efforts.

Competitive pricing comes from efficient operations and strategic sourcing. On-time delivery maintains your production schedules. Customer-focused service builds lasting partnerships based on trust and reliability.

|

|

|

|

|

|

Feedback from customers

|

|

|

FAQs

Q: What makes Grade 2 different from other titanium grades?

A: Grade 2 offers the best balance of strength, formability, and corrosion resistance among commercially pure grades.

Q: Can you provide small quantities for prototyping?

A: Yes, we accommodate prototype quantities and sample requests.

Q: What surface finishes are available?

A: We offer hot rolled, cold rolled, and polished finishes to meet your application needs.

Q: Do you provide material certificates?

A: Every shipment includes complete mill test certificates with chemical and mechanical test results.

Contact Us

Ready to discuss your titanium sheet grade 2 requirements? Our experienced team is here to help you find the perfect solution. Contact us today for detailed quotations, technical specifications, or application guidance. We look forward to becoming your trusted titanium supplier.

E-mail: info@chdymetal.com

Mob./what'sapp: 86-18049386902

Learn about our latest products and discounts through SMS or email