- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

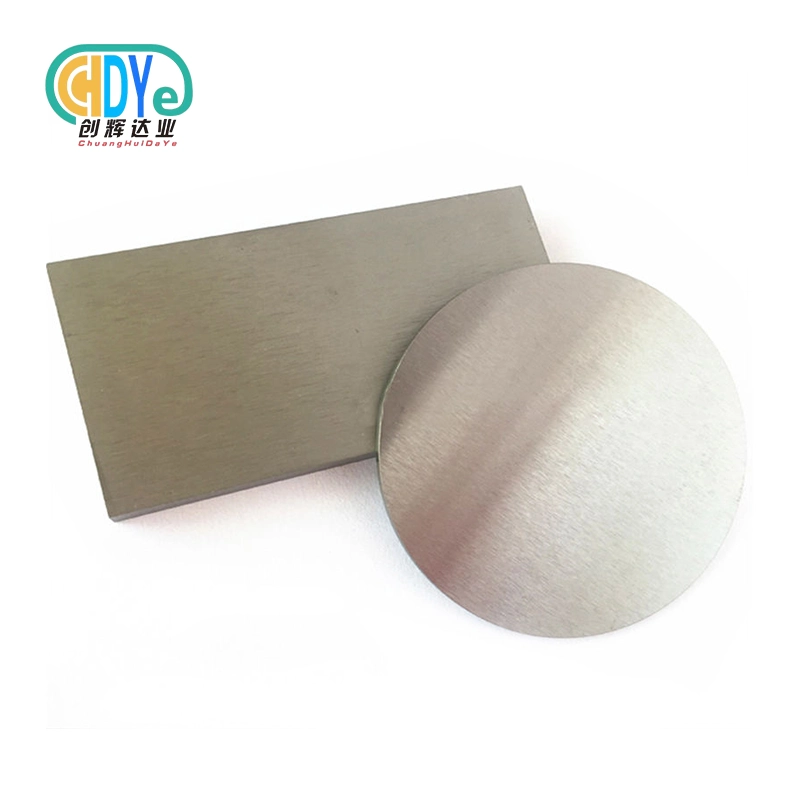

high purity niobium bar rod

2.Grade:RO4200, RO4210

3.Purity: 99.99%

4.Certificate: ISO9001:2015

When you need exceptional performance materials for critical applications, our high purity niobium bar rod delivers unmatched quality and reliability. With over 99.9% purity levels, these precision-engineered bars meet the demanding requirements of aerospace, electronics, and high-temperature industrial applications. Our company brings three decades of rare metal expertise to every product we manufacture.

Product Introduction

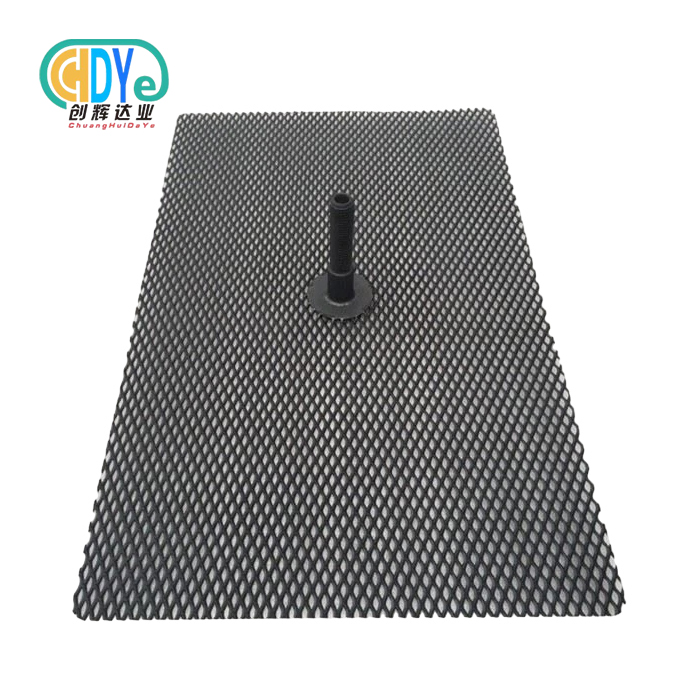

Our niobium bars represent the pinnacle of metallurgical excellence. Each rod undergoes rigorous quality control processes to ensure consistent performance across demanding applications. The soft, ductile nature of niobium makes it ideal for specialized manufacturing processes while maintaining exceptional corrosion resistance.

Key Features and Benefits

- Superior Purity: Exceeds 99.9% niobium content for critical applications

- Excellent Corrosion Resistance: Performs reliably in harsh chemical environments

- High Temperature Stability: Maintains properties at elevated temperatures

- Outstanding Ductility: Easy to machine and form into complex shapes

- Low Neutron Capture: Perfect for nuclear industry applications

- Biocompatible: Safe for medical device manufacturing

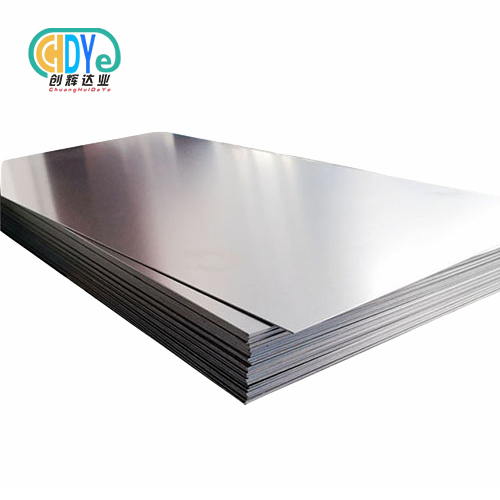

Technical Specifications

| Property | Specification |

|---|---|

| Alloy Composition | Nb >99.9% |

| Diameter Range | φ3-φ350mm |

| Length | as your request |

| Density | 8.57 g/cm³ |

| Tensile Strength | 200-350 MPa |

| Melting Point | 2,477°C |

| Thermal Conductivity | 53.7 W/m·K |

| Condition | Annealed |

| Standard | ASTM B 365 |

| Certificate | ISO 9001:2015 |

| Delivery time | Normal production time need about 10-15 working days |

| Peyment terms | 30% TT in advance, 70% balance before shipment |

Chemical composition

|

Material |

Main elements(%) |

Impurities (Maximum %) |

||||||||||

|

Nb |

Fe |

Si |

Ni |

W |

Mo |

Ti |

Ta |

O |

C |

H |

N |

|

|

RO4200 |

Remainder |

0.004 |

0.004 |

0.002 |

0.005 |

0.005 |

0.002 |

0.07 |

0.015 |

0.0040 |

0.0015 |

0.003 |

|

RO4210 |

Remainder |

0.01 |

0.01 |

0.005 |

0.02 |

0.01 |

0.004 |

0.10 |

0.02 |

0.01 |

0.0015 |

0.01

|

Mechanical Properties

|

Grade |

Tensile strength psi(MPa), ≥ |

Yield strength δ0.2, psi (MPa),≥ |

Elongation in 1"/2" gage length, %, ≥ |

|

|

>=0.010 |

<0.010 |

|||

|

RO4200 RO4210 |

18000 (125) |

12000 (85) |

25 |

20 |

Available Grades and Materials

We offer various grades to meet your specific requirements:

- R04200: Commercial pure niobium

- R04210: Niobium with controlled oxygen content

- Custom Alloys: Tailored compositions for specialized applications

Manufacturing Process

Our advanced manufacturing process ensures consistent quality. We start with premium raw materials and employ vacuum melting techniques. Cold working and heat treatment optimize mechanical properties. Each batch undergoes comprehensive testing before shipment.

|

|

|

|

|

|

|

|

Applications and Industries

Aerospace Industry: Engine components, heat shields, and structural elements benefit from niobium's high-temperature performance.

Electronics Sector: Capacitors and superconducting devices utilize niobium's unique electrical properties.

Nuclear Energy: Reactor components leverage niobium's low neutron absorption characteristics.

Medical Devices: Biocompatible implants and surgical instruments rely on niobium's safety profile.

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

Standard diameter tolerances: ±0.1mm for diameters under 10mm, ±0.2mm for larger sizes. Length tolerances maintain ±5mm accuracy. Custom dimensions available upon request to meet your exact specifications.

Product Features in Detail

The crystalline structure of our high purity niobium bar rod provides exceptional workability. You can easily machine, weld, or form these bars without compromising their inherent properties. The material's resistance to most acids and alkalis ensures long-term reliability in corrosive environments.

Quality Assurance and Testing

Every shipment includes comprehensive material certifications. We conduct chemical analysis, mechanical testing, and dimensional verification. Our quality management system ensures traceability from raw materials through final inspection.

|

|

|

OEM & Customization Services

We understand that standard specifications don't always meet unique requirements. Our engineering team works closely with you to develop custom solutions. Whether you need specific alloy compositions, unique dimensions, or special surface treatments, we deliver tailored products.

Packaging and Shipping

Professional packaging protects your investment during transit. We use moisture-resistant materials and secure cushioning. Products ship via reliable carriers with full insurance coverage. Expedited shipping options available for urgent requirements.

|

|

|

|

|

|

|

|

|

Why Choose Us

Located in China's "Titanium Capital," we bring unparalleled expertise to rare metal manufacturing. Our founder's 30+ years of industry experience ensures you receive products that meet the highest standards. We've successfully served customers in over 50 countries worldwide.

Your satisfaction drives our commitment to excellence. We provide competitive pricing without compromising quality. On-time delivery and responsive customer service make us your trusted partner for high purity niobium bar rod requirements.

|

|

|

|

|

|

FAQs

Q: What minimum order quantities do you require?

A: We accommodate both small prototype quantities and large production runs.

Q: Can you provide material certificates?

A: Yes, complete material certifications accompany every shipment.

Q: What's your typical lead time?

A: Standard products ship within 1-2 weeks. Custom specifications may require additional time.

Q: Do you offer technical support?

A: Our experienced engineering team provides comprehensive technical assistance.

Contact Us

Ready to discuss your high purity niobium bar rod requirements? Our experts are standing by to help you select the perfect material for your application. Contact us today for detailed quotes and technical specifications. We look forward to partnering with you on your next project.

E-mail: info@chdymetal.com

Mob./what's app:: 86-18049386902

Learn about our latest products and discounts through SMS or email