- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

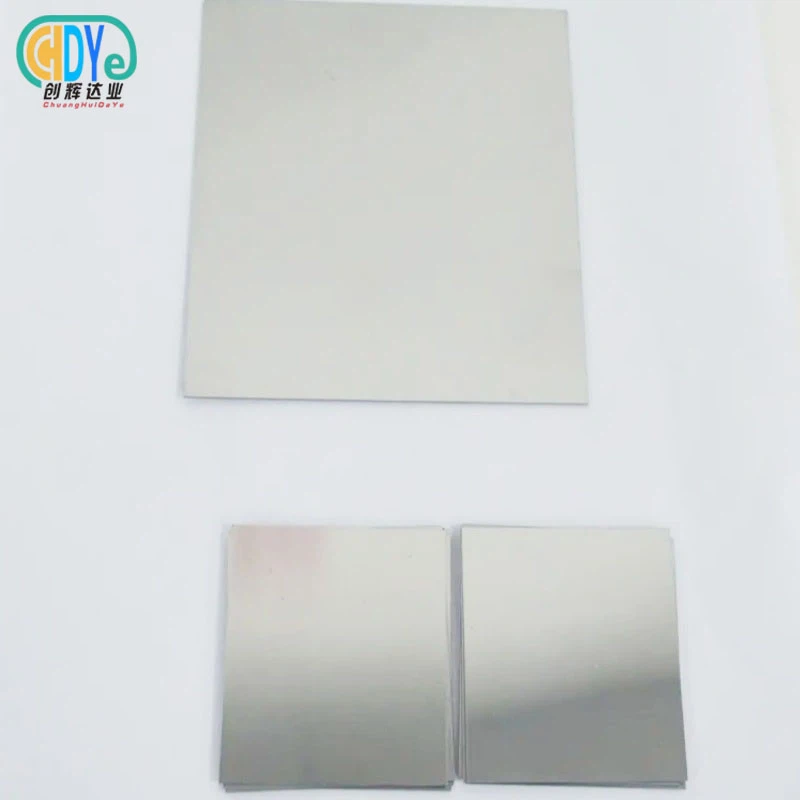

Ti-6Al-4V Titanium Sheet

Product Details

Ti-6Al-4V Titanium Sheet is one of the most widely used α+β titanium alloys, known for its outstanding balance between strength, toughness, corrosion resistance, and workability. This alloy typically contains 6% aluminum and 4% vanadium, enhancing its mechanical stability and heat resistance, making it ideal for demanding structural and high-performance applications.

It is commonly used in aerospace components, marine equipment, high-end industrial machinery, and precision medical devices. The sheet form offers excellent formability and weldability, which allows manufacturers to process it into complex parts with stable performance under extreme environments.

Stock size

Width*Length : 1000 x 2000, 1220 x 2440 as common

Thickness: 0.8mm,1mm, 2mm 3mm, 4mm,5mm,6mm,8mm,10mm,12mm,15mm and customized

Standard: ASTM B 265

Condition: annealed

Technical Specifications

| Property | Specification |

|---|---|

| Material | Ti-6Al-4V (Grade 5) |

| Standard | ASTM B265 / AMS 4911 / ISO 5832-3 |

| Thickness Range | 0.5 mm – 60 mm |

| Width Range | 100 mm – 1500 mm |

| Length Range | 500 mm – 4000 mm |

| Tensile Strength | ≥ 895 MPa |

| Yield Strength | ≥ 830 MPa |

| Elongation | ≥ 10% |

| Density | 4.43 g/cm³ |

| Surface Finish | Pickled / Polished / Bright / Brushed |

Product Features and Advantages

-

High Strength-to-Weight Ratio – Excellent for lightweight structural designs requiring superior mechanical properties.

-

Outstanding Corrosion Resistance – Performs reliably in saltwater, acidic, and oxidizing environments.

-

Excellent Heat Resistance – Maintains strength up to 400°C, suitable for aerospace and automotive thermal systems.

-

Good Formability and Machinability – Compatible with conventional machining, rolling, and stamping processes.

-

Reliable Welding Capability – Can be welded using TIG or electron beam techniques without compromising integrity.

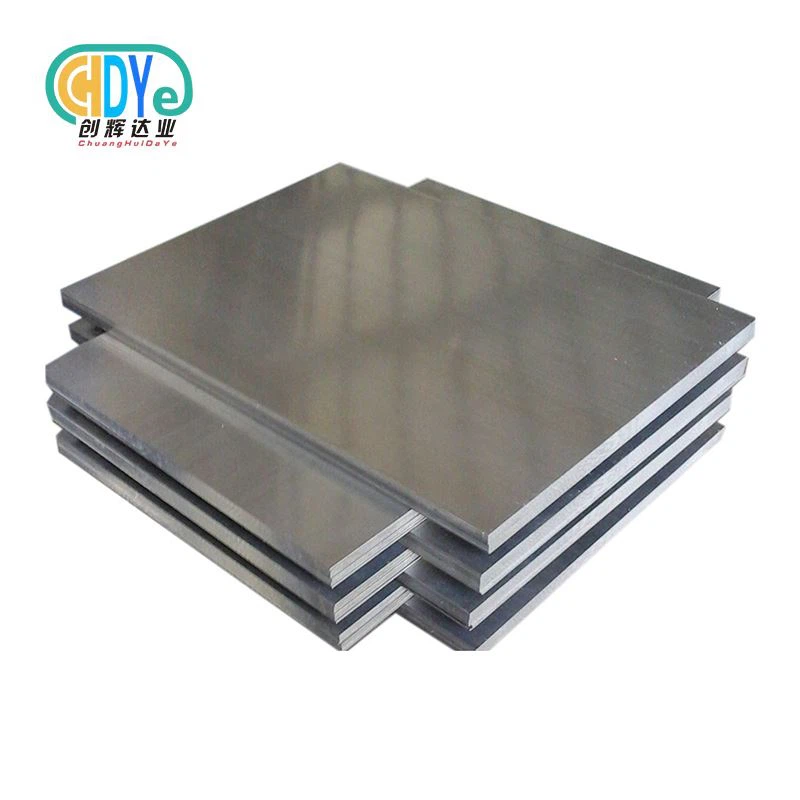

Manufacturing & Processing Capability

Shaanxi Chuanghui Daye Metal Material Co., Ltd. operates a fully integrated titanium production line covering melting, forging, rolling, annealing, and surface finishing. All Ti-6Al-4V sheets are melted in vacuum arc furnaces to ensure purity and stable alloy composition.

Advanced hot and cold rolling technologies guarantee precise dimensional accuracy, smooth surface finish, and consistent mechanical properties across the entire plate.

|

|

|

|

|

|

|

|

Quality Assurance

Each batch undergoes strict testing according to ASTM and ISO standards, including:

- Chemical composition analysis by spectrometry

- Tensile and yield strength verification

- Ultrasonic flaw detection and microstructure evaluation

- Surface inspection for flatness and roughness

- Dimensional accuracy and tolerance confirmation

All test data and mill certificates are provided with the shipment for complete traceability.

Application Advantages

- This alloy sheet is a preferred choice in high-strength, lightweight applications, including:

- Aerospace fuselage panels, brackets, and engine components

- Marine structural parts and corrosion-resistant systems

- High-performance automotive and racing components

- Medical surgical tools and orthopedic implants

- Chemical processing and pressure vessel applications

Be used in a wide range of industries.

Marine engineering

Medical implants

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

R&D and Customization

Our R&D department focuses on improving alloy performance for extreme operating conditions. We collaborate with customers to customize the mechanical strength, surface texture, and sheet thickness according to specific end-use requirements.

We also offer OEM and ODM services for aerospace, industrial, and medical clients, providing small-batch trials, prototype production, and precision cutting services.

Packaging & Logistics

Each titanium sheet is wrapped with corrosion-resistant film, packed in wooden crates with moisture-proof protection, and clearly labeled for grade and batch tracking.

We work with reliable international freight partners to ensure fast and safe global delivery for wholesale buyers.

|

|

|

|

|

|

|

|

|

|

|

|

Global Market & Cooperation

We have long-term partnerships with aerospace and industrial clients across Europe, North America, and East Asia. The factory holds certifications under ISO 9001, ISO 13485, and CE standards, ensuring global compliance.

We welcome wholesale distributors, OEM manufacturers, and project contractors to discuss bulk purchase, custom production, and strategic cooperation.

Feedback from customers

Why Choose Us :

1. You can get the perfect material according to your requirement at the least possible price.

2. We offer FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

3. The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

4. You can get stock alternatives, mill deliveries with minimizing manufacturing time.

5. We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

Sample order is supported!

|

|

|

|

|

|

Ti-6Al-4V Titanium Sheet Transaction Process

1.First contact us to provide the grade, size ,quantity and standard or any special requirements.

2.we will reply you the quotation with delivery time in 3 hours.

3.reach an agreement then buyer arrange the prepayment.

4. when we get your payment we will arrange production asap and share you the production progress.

5.when production finished, will give buyer the actual weight of the products, then the buyer arrange balance payment.

6. Arrange shipment according to the most economical form we have agreed on

7.Meanwhile send buyer the material certificate.

8. Regular after-sales service to know the actual product usage.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Chdymetal have more than 30year's experience in Non-ferrous metal industry, Ti-6Al-4V Titanium Sheet is one of our main products, we have common size in stock all year round and we can arrange 1-3days quick delivery.

Welcome to contact us for more information: info@chdymetal.com/ Mob.: 86-18049386902

Learn about our latest products and discounts through SMS or email