- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

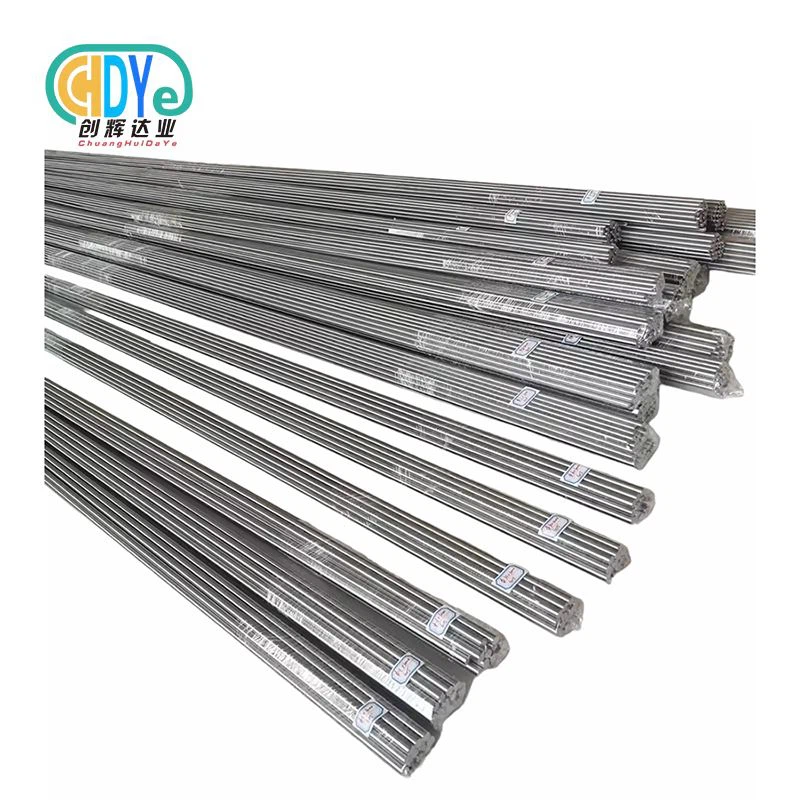

Titanium Seamless Tube

2.Standard: ASTM B338 ASTM B337 B861 B862

3.Dimension:OD10-300xWT0.5-10x L100-18000 MM

Product Introduction

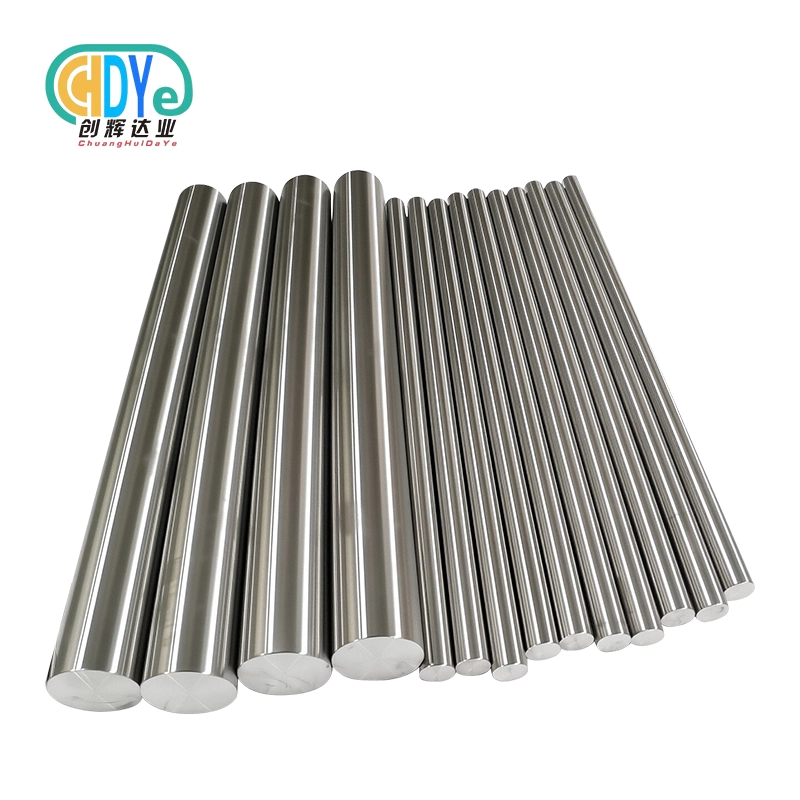

Titanium seamless tube is a high-performance tubular product manufactured from premium-grade titanium and titanium alloys through advanced seamless processing techniques. It features exceptional corrosion resistance, low density, high strength-to-weight ratio, and superior mechanical properties at both high and low temperatures.

Shaanxi Chuanghui Daye Metal Material Co., Ltd. offers a full range of titanium seamless tubes for demanding industrial applications, ensuring each tube meets international standards such as ASTM B338, ASTM B861, AMS 4942, and ISO 9001:2015.

As a professional manufacturer with over 30 years of experience in titanium and rare metal production, we provide precision-engineered seamless tubes that deliver reliable performance in the most challenging environments.

Titanium tubes are light in weight, high in strength and superior in mechanical properties. It is widely used in heat exchange equipment, such as tube heat exchanger, coil heat exchanger, serpent tube heat exchanger, condenser, evaporator and pipeline, etc.

1.Item Name: titanium seamless tube

2.Grade :Gr1 Gr2 Gr7 Gr9 Gr12

3.Standard: ASTM B338 ASTM B337 B861 B862

4.Dimension:OD10-300xWT0.5-10x L100-18000 MM

5.Condition: annealed

6.Type: seamless and welded

7. titanium seamless tube Application

1)heat exchanger and Condenser; U Type coil pipe ;

2)Petroleum pipeline ; Sea farming;

3)Evaporator; Fluid Transportation Piping etc.

Mechanical properties Titanium seamless Tubes

|

Grade |

Tensile Strength, min |

Yield Strength (0.2% Offset) |

Elongation 2 in. or 50 mm |

||||

|

min |

max |

||||||

|

Ksi |

(Mpa) |

Ksi |

(Mpa) |

Ksi |

(Mpa) |

gage length min % |

|

|

Grade 1 |

35 |

-240 |

25 |

-170 |

45 |

-310 |

24 |

|

Grade 2 |

50 |

-345 |

40 |

-275 |

65 |

-450 |

20 |

|

Grade 3 |

65 |

-450 |

55 |

-380 |

80 |

-550 |

18 |

|

Grade 5 |

130 |

-895 |

120 |

-828 |

… |

… |

10 |

|

Grade 7 |

50 |

-345 |

40 |

-275 |

65 |

-450 |

20 |

|

Grade 9 |

90 |

-620 |

70 |

-483 |

45 |

… |

15 |

|

Grade 11 |

35 |

-240 |

25 |

-170 |

… |

-310 |

24 |

|

Grade 12 |

70 |

-483 |

50 |

-345 |

… |

… |

18 |

|

Grade 23 |

120 |

-828 |

110 |

-759 |

… |

… |

10 |

Product Features & Advantages

- Excellent Corrosion Resistance: Resistant to seawater, acids, alkalis, and chlorides, ideal for marine and chemical applications.

- High Strength-to-Weight Ratio: Combines lightweight properties with exceptional tensile strength.

- Superior Heat Resistance: Maintains stability and performance up to 600°C.

- Excellent Biocompatibility: Safe for use in medical and pharmaceutical equipment.

- Long Service Life: Outstanding fatigue resistance and durability under cyclic stress.

- Custom Machinability: Available in various dimensions and surface finishes to meet specific application requirements.

Application Advantages

Titanium seamless tubes from Shaanxi Chuanghui Daye are used extensively across diverse industries, including:

- Chemical Processing: Heat exchangers, evaporators, and condensers handling corrosive fluids.

- Marine Engineering: Desalination plants, offshore pipelines, and seawater systems.

- Aerospace Industry: Hydraulic systems, engine components, and aircraft frames.

- Medical Devices: Surgical implants, orthopedic supports, and heat exchangers in medical systems.

- Power Generation: Condenser tubes in nuclear and thermal power plants.

- Oil & Gas: Downhole tubing, heat exchangers, and corrosion-resistant pipelines.

Our tubes provide long-term stability and reliability under harsh operating conditions, ensuring efficiency and safety in all installations.

Be used in a wide range of industries.

Marine engineering

Medical implants

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

-

We utilize world-class production equipment and strict process control to ensure consistent quality:

-

Melting & Forging: Electron beam and vacuum arc remelting for high-purity ingots.

-

Tube Extrusion & Pilgering: Precision rolling and drawing ensure uniform wall thickness.

-

Annealing & Straightening: Controlled heat treatment to enhance ductility and mechanical strength.

-

Surface Treatment: Pickling and polishing for smooth, corrosion-resistant finishes.

-

Testing & Inspection: Each tube undergoes eddy current, ultrasonic, and hydrostatic tests.

Our experienced engineering team ensures all processes conform to international metallurgical and dimensional standards.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Quality is central to our operations.

We are ISO 9001:2015 certified and maintain a full traceability system for all titanium seamless tube production. Every step—from raw material inspection to final delivery—is carefully monitored to ensure product reliability and compliance.

Comprehensive testing methods include:

- Mechanical property tests (tensile, yield, elongation)

- Non-destructive testing (ultrasonic and eddy current)

- Dimensional and visual inspections

- Corrosion resistance and metallographic analysis

Only after passing all evaluations are products released for shipment.

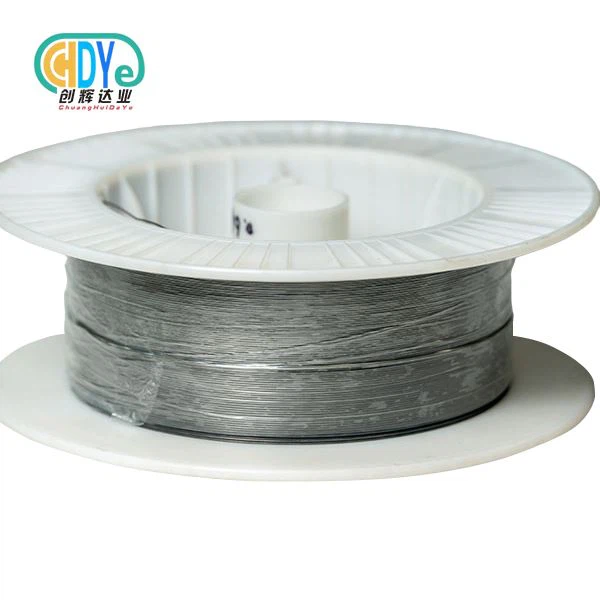

R&D and Customization

- Customized mechanical strength and elongation through controlled annealing

- Tailored coil or straight length for automated production lines

- Surface finish customization: pickled, mirror-polished, or bright annealed

- OEM packaging, logo, and labeling for international distributors

- Prototype development for advanced alloys and new applications

Our R&D team continuously works with aerospace, chemical, and medical sectors to optimize titanium wire performance and cost-efficiency.

Packaging & Global Logistics

To guarantee safe and secure delivery, we follow international export packaging standards:

- Inner Packaging: Vacuum-sealed or anti-rust film wrapping.

- Outer Packaging: High-strength wooden cases with foam cushioning.

- Labeling: Detailed product specifications, batch numbers, and inspection reports attached.

- Shipping Options: Air, sea, and land transportation available worldwide with full tracking.

Each shipment is protected against moisture, vibration, and mechanical impact to ensure product integrity upon arrival.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

We provide complete OEM and customization options to meet specific client requirements:

-

Custom size and tolerance machining

-

Alloy composition adjustment for special applications

-

Prototype development and small-batch production

-

Technical consulting and engineering support

-

Private labeling and export documentation assistance

Our engineering team works closely with customers to develop tailored titanium seamless tube solutions optimized for performance and cost-efficiency.

Titanium seamless tube Inspection Process

1. Appearance and dimension inspection to ensure every titanium tube meets tolerances,no cracks, pits or other defects on the surface.

2. 100% Straightness inspection.

3. 100% Hydro Testing.

4. Ultrasonic and eddy current testing make sure the product without cracks and scratch.

5. Testing Tensile strength, yield strength by our Tension Tester and the Third party lab to double check the quality.

Why Choose Us

1.ISO 9001 certified company

2.100% inspection before shipment and provide Mill test certificate

3.Quick delivery and economical freight cost

4. Prompt reply you can get our reply within 2-5 hours

one-stop solution

professional team

high quality

Shaanxi Chuanghui Daye Metal Material CO.,Ltd (Chdymetal)have titanium seamless tube common sizes in stock all year round. Please contact us to confirm the specific delivery time.

|

|

|

|

|

|

FAQs

Q1: What standards do your tubes conform to?

A1: We produce according to ASTM B338, ASTM B861, and AMS 4942, ensuring full international compliance.

Q2: Can you supply small quantities for trial use?

A2: Yes, we support sample and small-batch production for testing and R&D projects.

Q3: What is your typical lead time?

A3: Standard sizes can be shipped within 7 days; customized orders typically take 2–3 weeks.

Q4: Do you provide inspection certificates?

A4: Yes, all deliveries include EN 10204 3.1 inspection reports and chemical/mechanical test data.

Q5: What are your main export markets?

A5: We export to the United States, Germany, France, South Korea, Singapore, and more than 50 other countries worldwide.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email