- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Niobium titanium alloy rod

2. Diameter: 1–65 mm

3. Rectangular or round

4. Length: 6000 mm max

Product Introduction

Looking for reliable industrial metal solutions? Our niobium titanium alloy rod delivers exceptional performance for your most demanding applications. Whether you need materials for aerospace components, chemical processing equipment, or specialized industrial applications, our niobium rods provide the reliability you can trust. Each bar meets strict quality standards and comes with comprehensive technical support to ensure your project success.

Key Features and Benefits

- Excellent Corrosion Resistance: Withstands harsh chemical environments

- Biocompatible Properties: Safe for medical and food-grade applications

- High Temperature Stability: Maintains strength at elevated temperatures

- Precision Manufacturing: Tight tolerances for critical applications

- Versatile Sizing Options: Available in multiple diameters and lengths

Technical Specifications

|

Product name |

niobium titanium alloy rod |

|

Grade |

Nb50%-Ti50%, Nb53%-Ti47% and Nb45%-Ti55% |

|

Size |

Diameter 3-70mm, length max 6000mm |

|

Melting point |

2468℃ |

|

Boiling point |

4742℃ |

|

Advantage |

♦ Low Density and High Specificate Strength |

|

♦ Excellent Corrosion Resistance |

|

|

♦ Good resistance to effect of heat |

|

|

♦ Nonmagnetic and Non-toxic |

|

|

♦ High melting point, good anti-corrosion, excellent super-conduction and other unique characteristics. |

|

|

Application |

♦ Superconductor, Electronic industry, Chemistry, Electronical, Pharmaceutical industry. |

|

♦ Steel, Ceramics, Electronics, nuclear energy industries and superconductor technology. |

|

|

♦ Super condouctous, metled cast ingots and alloying agents. |

|

|

♦ Widely used in manufacturing various kinds of alloy steel, high temperature alloy, optical glass, cutting tool, superconducting |

Manufacturing Process

Our manufacturing process combines advanced metallurgical techniques with strict quality control. We start with high-purity niobium feedstock, then use precision forming methods to achieve exact dimensions. Each niobium titanium alloy rod undergoes multiple quality checks throughout production to ensure it meets your specifications.

|

|

|

|

|

|

|

|

Applications and Industries

Aerospace Industry: Jet engine components, rocket parts, and heat-resistant assemblies

Chemical Processing: Corrosion-resistant equipment and reactor components

Medical Devices: Biocompatible implants and surgical instruments

Electronics: Superconducting applications and specialized components

Research & Development: Laboratory equipment and experimental setups

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Other related titanium products

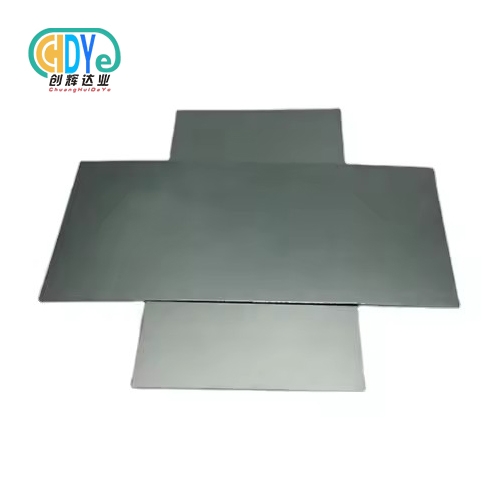

Niobium plate/ sheet/ foil/ strip

Niobium tube seamless tube and welded tube

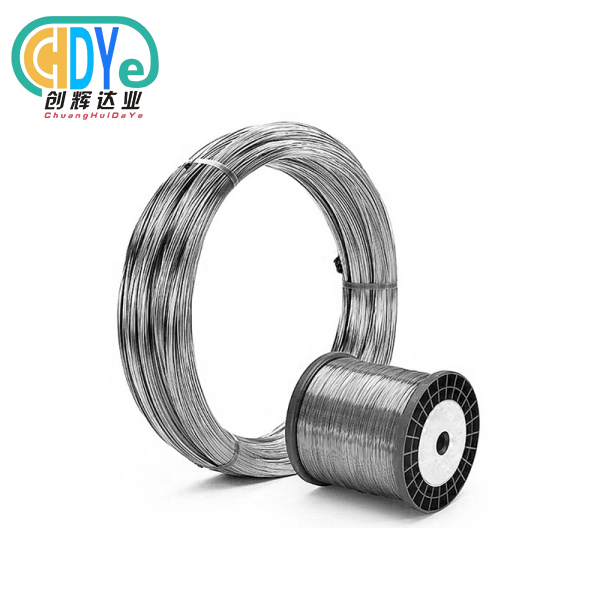

Niobium wire

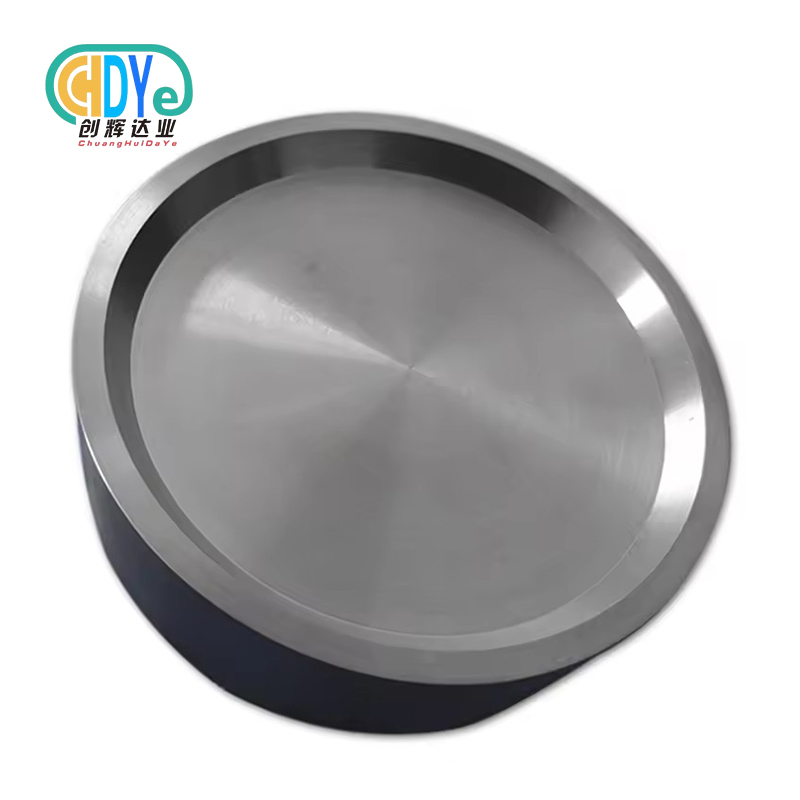

Other Niobium machined products such as niobium screw, Niobium crucible etc.

Quality Assurance and Testing

Every batch undergoes comprehensive testing including chemical composition analysis, dimensional verification, and mechanical property evaluation. We maintain detailed records for full traceability and provide certificates of analysis with each shipment.

OEM & Customization Services

We understand that every application has unique requirements. Our technical team works closely with you to develop custom solutions. From modified dimensions to special surface treatments, we can adapt our products to meet your specific needs.

Packaging and Shipping

Your orders receive careful packaging to prevent damage during transit. We use protective materials and secure containers appropriate for the size and quantity of your shipment. Our logistics team coordinates delivery to ensure timely arrival at your facility.

|

|

|

Why Choose Us

With over 30 years of experience in rare metals, we bring deep expertise to every project. Located in China's "Titanium Capital," we have access to premium raw materials and advanced manufacturing capabilities. Our commitment to quality and customer service has earned trust from clients in over 50 countries worldwide.

|

|

|

|

|

|

FAQs

Q: Can you provide custom dimensions?

A: Yes, we offer custom sizing beyond our standard range to meet specific requirements.

Q: What industries commonly use niobium rods?

A: Primary applications include aerospace, chemical processing, medical devices, and electronics.

Q: How do you ensure consistent quality?

A: We implement rigorous testing protocols and maintain strict quality control throughout manufacturing.

Contact Us

Ready to discuss your niobium rod requirements? Our technical experts are here to help you select the right specifications for your application. Contact us today at info@chdymetal.com for detailed quotations, technical support, or to learn more about our complete range of rare metal products.

Learn about our latest products and discounts through SMS or email