- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

high purity Vanadium Block

2.Density: 6.11g/cm3

2. Grade: V-3

3. Specifications: <40mm block, V 99.7%

4. Uses: Used in alloying additives.

Product Introduction

Welcome to our premium high purity Vanadium Block collection, designed for your most demanding industrial applications. Our vanadium blocks deliver exceptional purity levels of 99.95%, making them perfect for high-performance alloys and specialized manufacturing processes. With over 30 years of experience in the rare metal industry, we understand your need for reliable, consistent quality materials that perform under extreme conditions.

Our vanadium blocks feature a density of 6.0 g/cm³, ensuring uniform melting characteristics in your production processes. Each block is carefully manufactured to meet strict industrial standards, providing you with the consistency and reliability your operations demand.

Key Features and Benefits

- Ultra-High Purity: 99.95% purity ensures superior performance in critical applications

- Optimal Density: 6.0 g/cm³ provides excellent melting uniformity

- Versatile Sizing: Available in 25–120 mm blocks for various industrial furnaces

- Superior Hardness: 135–160 HV rating guarantees reliable machining properties

- Low Oxygen Content: ≤120 ppm enhances high-temperature performance

- Extreme Temperature Resistance: 1910°C melting point supports demanding conditions

- Minimal Impurities: Metal impurities ≤50 ppm for ultra-clean applications

Technical Specifications

|

Grade |

The Main component is not less than |

Impurity elements not more than |

||||||

|

V |

Fe |

Cr |

Al |

Si |

C |

O |

N |

|

|

V-1 |

Balance |

0.005 |

0.006 |

0.005 |

0.004 |

0.01 |

0.025 |

0.005 |

|

V-2 |

Balance |

0.02 |

0.02 |

0.01 |

0.004 |

0.02 |

0.035 |

0.01 |

|

V-3 |

99.5% |

0.10 |

0.10 |

0.05 |

0.05 |

---- |

0.08 |

---- |

Available Grades and Materials

Our high purity Vanadium Block products are available in multiple grades to meet your specific requirements:

- V-3 Grade: 99.7% minimum purity for standard alloying applications

- Premium Grade: 99.95% purity for aerospace and medical applications

- Custom Grades: Tailored specifications available upon request

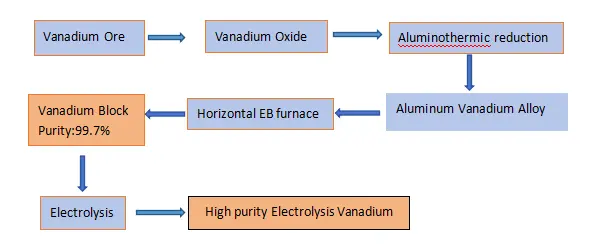

Manufacturing Process

We employ advanced manufacturing techniques to ensure consistent quality:

- Raw Material Selection: Carefully sourced vanadium materials

- Purification Process: Multi-stage refining for ultra-high purity

- Controlled Melting: Precision temperature control during formation

- Quality Testing: Comprehensive analysis of each batch

- Final Inspection: Dimensional and purity verification

|

|

|

|

|

|

|

|

Applications and Industries

Your vanadium blocks serve critical roles across multiple industries:

- Steel Industry: Alloying additive for high-strength steels

- Aerospace: Component manufacturing for extreme environments

- Automotive: High-performance engine components

- Chemical Processing: Catalyst applications

- Electronics: Specialized alloy production

- Defense Applications: Military-grade equipment manufacturing

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

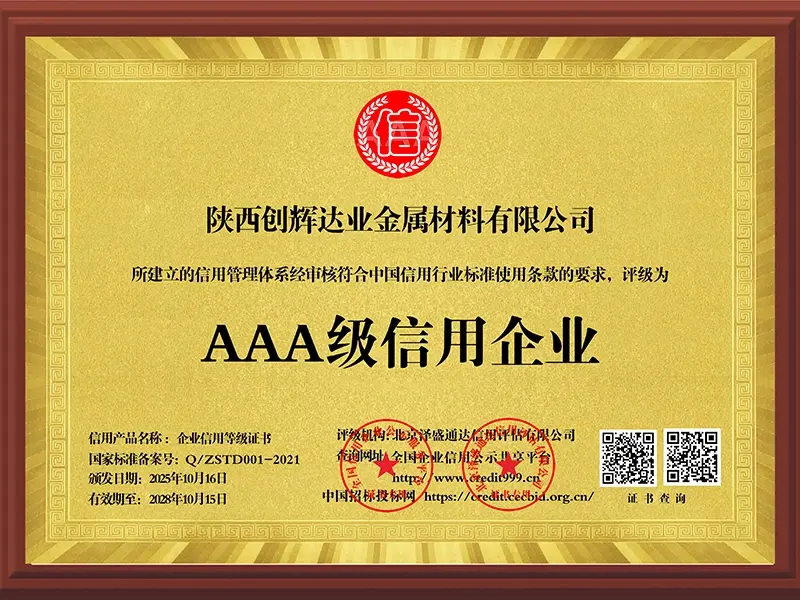

Quality Assurance and Testing

Every batch undergoes rigorous testing protocols:

- Chemical Composition Analysis: ICP-MS verification

- Dimensional Inspection: Precision measurement tools

- Surface Quality Check: Visual and microscopic examination

- Purity Verification: Multi-point sampling analysis

- Documentation: Complete traceability certificates

OEM & Customization Services

We understand that your applications may require specific dimensions or purity levels. Our team works closely with you to develop customized solutions that meet your exact specifications. Whether you need special sizing, particular purity grades, or unique packaging requirements, we're here to help.

Packaging and Shipping

Your high purity Vanadium Block orders are carefully packaged to ensure product integrity:

- Protective Packaging: Individual wrapping prevents contamination

- Secure Boxing: Sturdy containers for safe transport

- Documentation: Complete certificates and test reports included

- Global Shipping: Reliable delivery to over 50 countries worldwide

Why Choose Us

Located in Baoji High-tech Development Zone, known as China's "Titanium Capital," we bring decades of expertise to every order. Our founder's 30+ years in the rare metal industry ensures you receive products backed by deep knowledge and proven experience.

We focus on delivering competitive costs, on-time delivery, and customer-focused service. Trust, reliability, and honesty form the foundation of our business relationships.

|

|

|

|

|

|

FAQs

Q: What's the minimum order quantity?

A: We accommodate various order sizes to meet your specific needs.

Q: Do you provide material certificates?

A: Yes, complete test certificates accompany every shipment.

Q: Can you customize block dimensions?

A: Absolutely! We offer custom sizing based on your requirements.

Q: What's your typical lead time?

A: Standard products ship within 2-3 weeks; custom orders may require additional time.

Contact Us

Ready to discuss your vanadium block requirements? Our technical team is standing by to help you select the perfect high purity Vanadium Block for your applications.

Email: info@chdymetal.com

Contact us today for quotes, technical specifications, or to learn more about our comprehensive rare metal solutions. We're committed to providing you with the quality materials and exceptional service your business deserves.

Learn about our latest products and discounts through SMS or email