- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

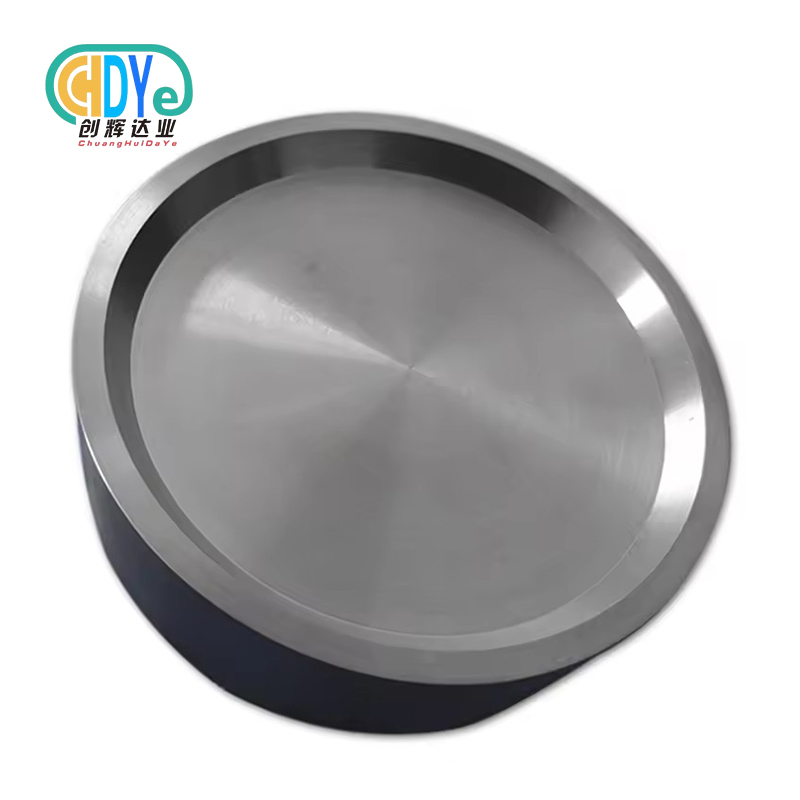

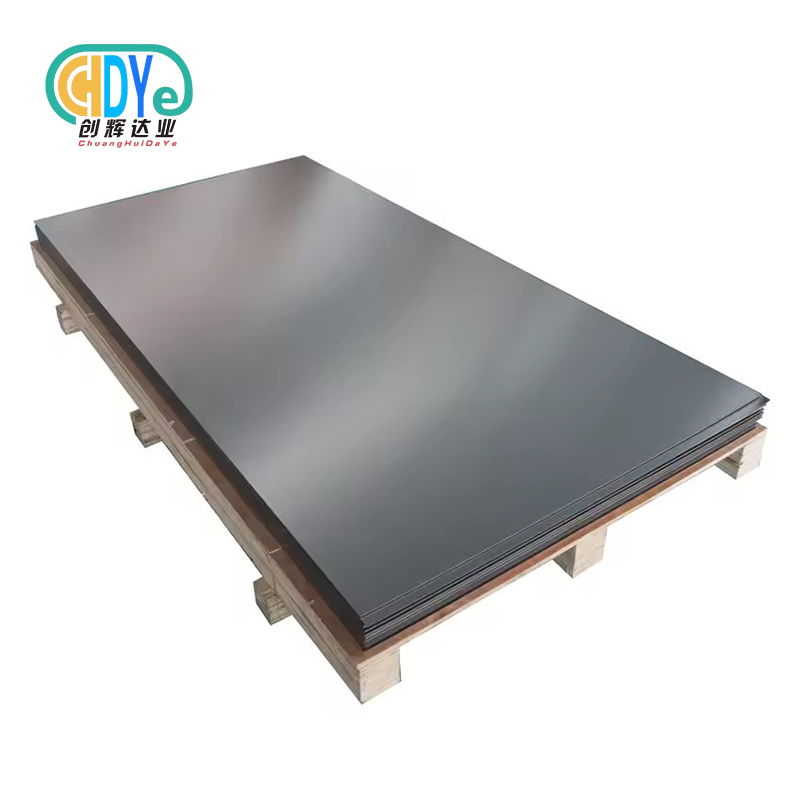

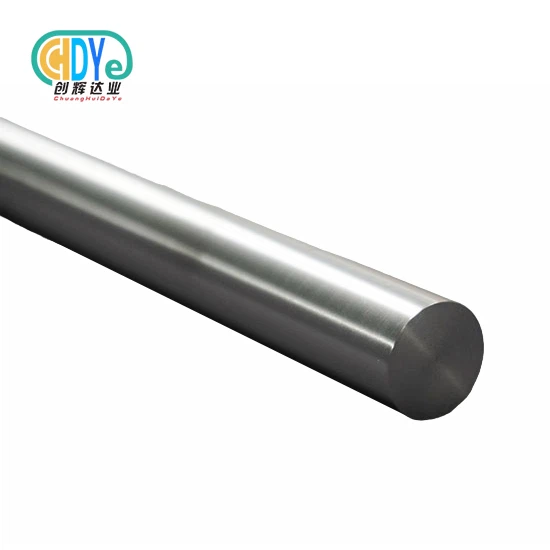

Tungsten Bar For Sale

2.Processing method: Sintering, forging, rotary forging, rolling, and polishing.

Product Introduction

The Tungsten Bar For Sale from Shaanxi Chuanghui Daye Metal Material Co., Ltd. is manufactured using premium-grade tungsten powder through advanced powder metallurgy technology. With a purity of up to 99.95%, our tungsten bars deliver exceptional density, hardness, and high-temperature strength. Known for their superior thermal and electrical conductivity, these bars are widely used in high-performance industrial, electronic, and aerospace applications. Each Tungsten Bar For Sale undergoes precise sintering, forging, and machining to achieve excellent mechanical integrity and dimensional accuracy. Available in various sizes and customized specifications, this product provides a reliable and cost-effective solution for global clients seeking top-quality refractory materials.

Tungsten bar are produced through powder metallurgy, formed by powder pressing, and then sintered to obtain sintered tungsten bar. Forging sintered tungsten bar can result in a denser internal structure and better product performance.

1.Material and Grade: W1, W2

2.Processing method: Sintering, forging, rotary forging, rolling, and polishing.

Specification

|

Diameter φ mm |

Diameter Tolerance% |

|

|

Black tungsten rod |

Polished tungsten rod |

|

|

1≤φ<3.0 |

±1.5 |

±1.0 |

|

3.0≤φ<6.5 |

||

|

6.5≤φ<20 |

||

Chemical Composition

|

Grade |

Tungsten content |

Contents of impurity element |

|

|

Total content |

Each content |

||

|

W1 |

99.95% Min |

0.05%max |

0.01%max |

|

W2 |

99.92% min |

0.08%max |

0.01%max |

Application Advantages

Tungsten bar are widely used in multiple industries, including:

1. Tungsten rods can be used to make tungsten contacts, which can be used for car horns;

2. Tungsten rods can be used in sapphire furnaces and other high-temperature furnaces, mainly serving as heating elements, supports, connectors, and electrodes; It can also be used as electrodes in the rare earth smelting industry;

3. Tungsten rods can be used as spare parts in the semiconductor plasma injection industry;

4. Tungsten rods can be used to make parts for electric light sources and electric vacuum industries.

5. Tungsten rods can be used to make welding electrodes.

Be used in a wide range of industries.

Steel industry

Electronic devices

Furnace components

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

1. Mixed powder( Mixed powder machine)

2. Pressing( isostatic press)

3 .Sintering( Medium frequency sintering furnace)

4. Forging (press machine)rolling

5. Polishing (polishing machine)

Tungsten bar Features:

1. High hardness, high density, High strength, high heat resistant;

2. Excellent thermal and electrical conductivity;

3. Better arc burning loss resistance, erosion resistance;

4. Easy to be machined.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Quality is the foundation of Shaanxi Chuanghui Daye’s production philosophy. The Tungsten Bar For Sale is subjected to comprehensive inspection procedures at every stage:

- Chemical Analysis: Ensures tungsten purity of ≥99.95%.

- Ultrasonic Testing: Detects internal flaws and density inconsistencies.

- Dimensional Inspection: Confirms accuracy within tight tolerances.

- Mechanical Testing: Evaluates tensile strength, hardness, and elongation rate.

- Visual and Surface Inspection: Guarantees a clean, defect-free surface finish.

Each product is delivered with full documentation, including test certificates and batch traceability, in compliance with ISO 9001:2015 standards.

R&D and Customization

With over three decades of rare metal expertise, Shaanxi Chuanghui Daye’s R&D team continuously improves tungsten material properties and manufacturing techniques. Research focuses on:

- Enhanced high-temperature performance and oxidation resistance.

- Development of fine-grain and high-density tungsten materials.

- Customized alloys for specialized thermal and electronic applications.

- Precision machining and surface treatment for complex geometries.

Clients can request customized dimensions, grades, and mechanical specifications to meet specific project needs for Tungsten Bar For Sale.

Packaging & Global Logistics

Each Tungsten Bar For Sale is carefully packed to ensure maximum protection during international transport:

- Packaging: Anti-rust wrapping, vacuum sealing, and reinforced wooden boxes.

- Labeling: Clear product identification with grade, batch number, and weight.

- Transportation: Reliable shipping by air, sea, or land through trusted logistics partners.

Shaanxi Chuanghui Daye exports to more than 50 countries, ensuring prompt and safe delivery of every order.

|

|

|

|

|

|

|

|

|

|

|

|

OEM & Customization Service

To meet diverse customer demands, Shaanxi Chuanghui Daye provides full OEM and ODM services:

- Production according to customer blueprints and tolerance requirements.

- Prototype development and small-batch manufacturing.

- Technical guidance in material selection and processing.

- Confidential cooperation with global distributors and end-users.

Our OEM services ensure flexibility, high precision, and cost efficiency for clients across various industries.

Inspection Process

The inspection process for Tungsten Bar For Sale is meticulously designed to maintain consistent quality standards:

- Raw Material Verification: Chemical composition and purity analysis.

- In-Process Monitoring: Real-time supervision of sintering and forging parameters.

- Non-Destructive Testing: Ultrasonic and density evaluations for defect detection.

- Dimensional Verification: Coordinate measuring instruments ensure precision.

- Final Review: Packaging and documentation verified before dispatch.

These steps guarantee reliable and high-performance tungsten products that meet international standards.

Why Choose Us

- 30+ Years of Expertise: Strong technical background in refractory metal processing.

- Advanced Equipment: Electron beam furnaces, forging lines, and rolling machines ensure stable output.

- Strict Quality Assurance: ISO 9001:2015 certification guarantees full production traceability.

- Global Supply Network: Exporting to over 50 countries with professional logistics solutions.

- Customization Options: Support for non-standard specifications and specialized requirements.

- Rapid Delivery: Standard orders completed within 7 days.

- Excellent Customer Service: Technical consultation and after-sales support available worldwide.

Choosing Shaanxi Chuanghui Daye ensures long-term reliability, superior performance, and competitive pricing.

|

|

|

|

|

|

FAQs

Q1: What is the typical purity of your tungsten bar?

A1: Our bars have a tungsten purity level of 99.95% or higher, ensuring excellent mechanical and thermal properties.

Q2: Do you provide customized sizes and machining?

A2: Yes, Tungsten Bar For Sale can be customized according to drawings, specifications, and tolerance requirements.

Q3: Which industries use your tungsten bars the most?

A3: They are commonly used in aerospace, electronics, metallurgy, and medical radiation shielding industries.

Q4: What are the available surface finishes?

A4: We offer ground, polished, and machined finishes depending on customer needs.

Q5: How is packaging handled for export?

A5: Each tungsten bar is vacuum-packed, cushioned with foam, and placed in strong wooden cases that meet international transport standards.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email