- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

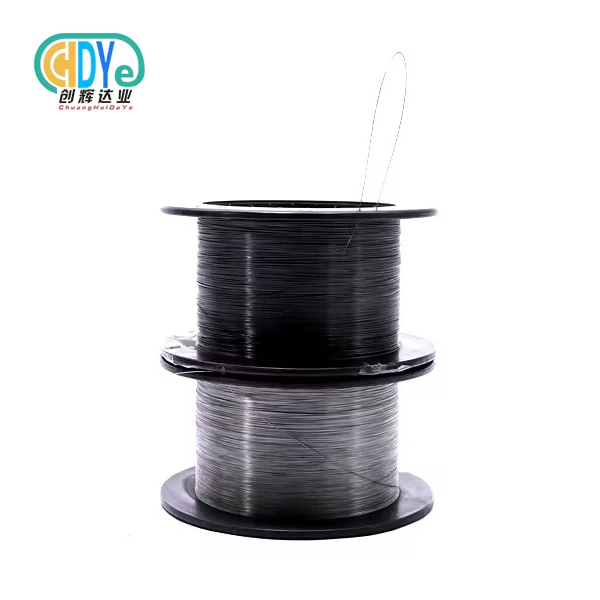

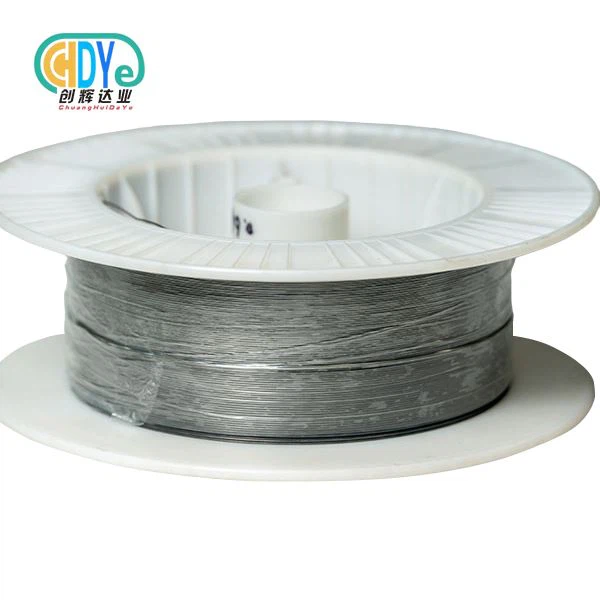

Tungsten Machined Parts

Product Introduction

The Tungsten Machined Parts from Shaanxi Chuanghui Daye Metal Material Co., Ltd. are precision-engineered components manufactured from ultra-high-purity tungsten. Designed for demanding industrial applications, these parts offer exceptional thermal conductivity, corrosion resistance, and mechanical stability at extreme temperatures. Suitable for both standard and customized specifications, the parts are engineered to meet international quality standards, ensuring reliable performance in sectors requiring high durability and precise tolerances.

Tungsten’s high melting point of 3422°C, combined with low thermal expansion and excellent wear resistance, makes these components ideal for high-temperature processing, vacuum systems, and electronic device manufacturing. The parts are also used in applications where chemical inertness and contamination-free performance are critical, providing consistent results in sensitive operations.

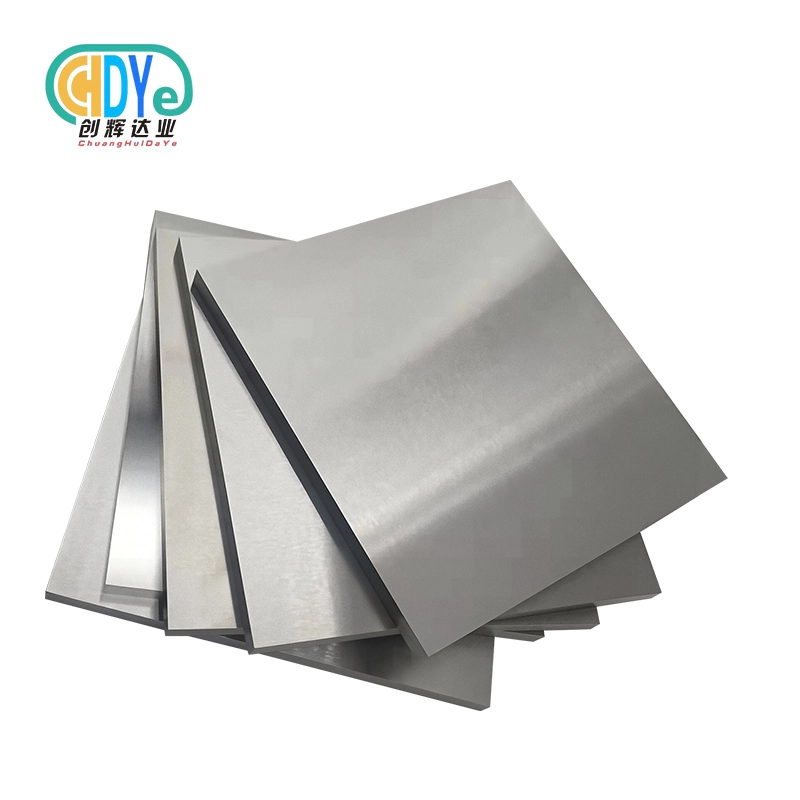

Specification

|

Name |

Tungsten machined parts |

|

Material |

Pure Tungsten |

|

Surface |

Polished |

|

Density |

19.3g/m3 |

|

Shape |

According to your drawing |

|

Chemical Composition |

99.95%min |

|

Packing |

Wooden Case |

|

Technique |

Forging |

|

MOQ |

1-5kg |

| Certification | ISO9001:2015 |

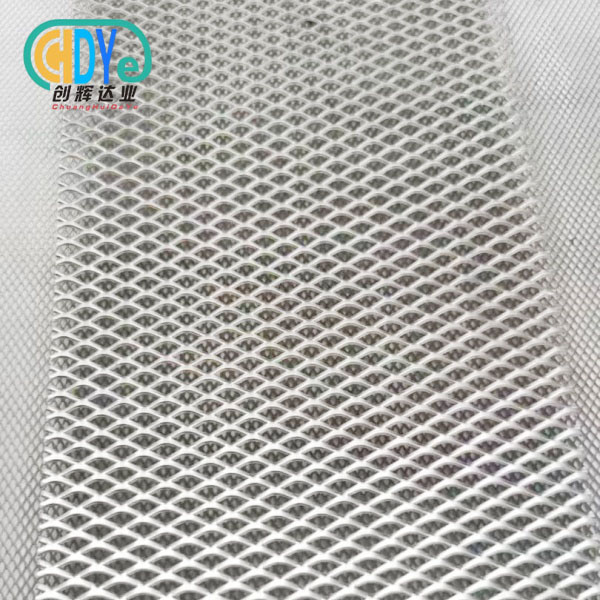

Tungsten machined parts Features

High purity powders are used as raw materials, with low impurity content and high sintering density.

Melting Point: 3410 °C

Boiling Point: 5927°C

Density: 19.2g/cm3

High quality, workability

Application Advantages

1. Industrial field

2. Aerospace field

3. Medical equipment

4. Electronic industry

5. Petrochemical industry

6. Decorative technology

7. Other applications

Be used in a wide range of industries.

Marine engineering

Medical implants

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

The production of these tungsten machined components involves meticulous processes:

- Raw Material Selection: Only ultra-high-purity tungsten ingots are selected, ensuring chemical consistency and structural integrity.

- Melting and Forging: Using advanced electron beam furnaces, tungsten is melted and forged to achieve desired mechanical properties.

- Precision Machining: CNC lathes and specialized milling equipment are employed to produce parts with tight tolerances and accurate dimensions.

- Surface Treatment: Polishing, stress-relief, and degassing processes enhance surface quality and thermal stability.

- Final Inspection: Each component undergoes rigorous quality checks for dimensional accuracy, mechanical strength, and surface integrity.

This precise manufacturing flow ensures consistent quality, long service life, and high performance in extreme operating conditions.

|

|

|

|

|

|

|

|

Quality Control & Inspection

At Shaanxi Chuanghui Daye, quality is central to the production of tungsten machined components:

- Material Purity Testing: Guarantees high chemical purity and minimal contamination.

- Dimensional Verification: Ensures that every part conforms to customer specifications.

- Mechanical & Thermal Performance Checks: Confirms stability under high-temperature operations.

- Surface Integrity Examination: Detects any microcracks, roughness, or defects that could impact performance.

- Batch Traceability: Each part is labeled with production data and batch numbers for full traceability.

These steps maintain the reliability and durability required in sensitive industrial applications.

R&D and Customization

Chuanghui Daye provides tailored R&D and customization services for Tungsten Machined Parts:

- Custom Dimensions and Geometries: Adapted for specific machinery and operational requirements.

- Prototype & Small-Batch Production: Supports specialized projects or experimental setups.

- Material Guidance and Process Consultation: Expert advice on tungsten selection, thermal management, and operational optimization.

- Design Optimization: Enhances thermal conductivity, mechanical performance, and evaporation efficiency.

Continuous R&D ensures customers receive high-performance, application-specific solutions.

Packaging & Global Logistics

To guarantee safe delivery, each component is carefully packaged and shipped worldwide:

- Wrapped in anti-rust and vacuum-sealed films to prevent oxidation.

- Foam padding and reinforced crates protect against impacts during transit.

- Labeled with specifications, batch numbers, and handling instructions for secure shipping.

- Reliable air, sea, and land logistics ensure prompt delivery to over 50 countries, including the United States, Germany, France, South Korea, and Singapore.

This approach ensures the parts arrive in optimal condition for immediate use.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Chuanghui Daye offers comprehensive OEM and customization services:

- Custom dimensions, wall thicknesses, and shapes for machinery-specific needs.

- Low-volume production and prototypes for experimental setups.

- Technical support for material selection, heat management, and process optimization.

- Post-sales consultation to ensure long-term performance and reliability.

These services allow clients to integrate the parts seamlessly into their operations.

Inspection Process

Each Tungsten Machined Part undergoes a strict inspection process:

- Incoming Material Verification: Ensures purity and structural integrity.

- Dimensional Accuracy Assessment: Confirms precise tolerances.

- Thermal and Mechanical Testing: Validates performance under extreme conditions.

- Surface Examination: Detects cracks, impurities, or defects.

- Final Quality Review and Packaging: Confirms readiness for global shipment.

This thorough inspection guarantees consistency and reliability across all delivered components.

Why Choose Us

Shaanxi Chuanghui Daye is a leading supplier of tungsten machined components:

- Over 30 years of experience in rare metal production.

- ISO 9001:2015 certified quality management system.

- Advanced equipment including electron beam furnaces, CNC lathes, rolling, and forging machines.

- Exported to more than 50 countries worldwide.

- OEM/ODM capabilities with professional technical support.

- Commitment to on-time delivery, competitive pricing, and superior product quality.

Our expertise ensures clients receive Tungsten Machined Parts that meet the highest industrial standards.

|

|

|

|

|

|

FAQs

Q1: What is the material used for these parts?

A1: Made from ultra-high-purity tungsten, they provide excellent thermal, mechanical, and chemical resistance.

Q2: Can I customize the size and shape?

A2: Yes, we offer full OEM/ODM customization for dimensions, geometry, and surface finish.

Q3: Which industries commonly use these parts?

A3: Electronics, semiconductors, aerospace, metallurgy, and research laboratories.

Q4: How are the parts packaged for delivery?

A4: Each unit is vacuum-sealed, cushioned with foam, and shipped in reinforced wooden crates.

Q5: Do you provide technical guidance?

A5: Yes, we provide expert advice on material selection, thermal management, and process optimization.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email