- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Gr2 Titanium Mesh

Product Overview

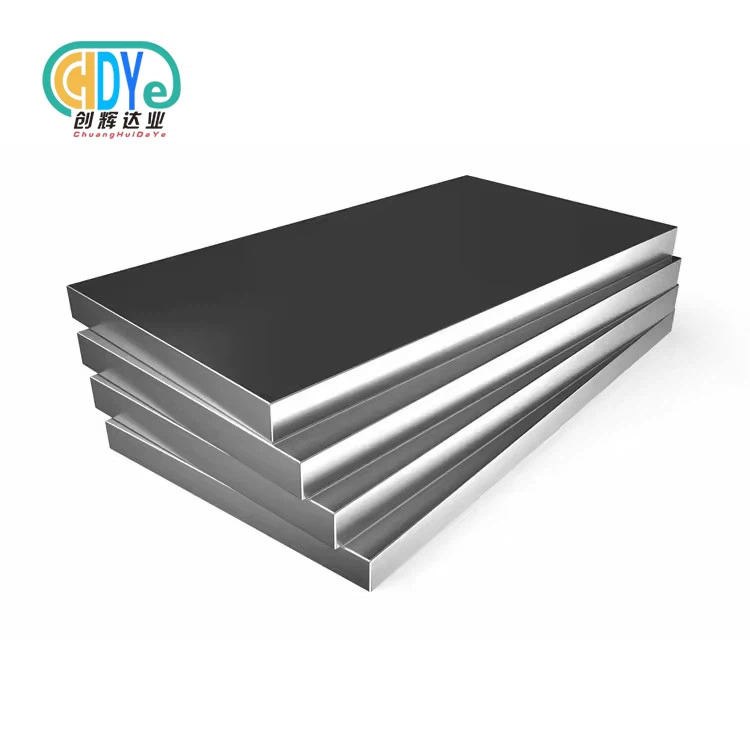

Gr2 Titanium Mesh is a high-purity, commercial-grade titanium mesh sheet (Grade 2) manufactured for industrial, chemical, marine, and filtration applications. Shaanxi Chuanghui Daye Metal Material Co., Ltd. produces Gr2 titanium mesh with superior corrosion resistance, mechanical strength, and excellent conductivity, ensuring long-term reliability even in aggressive chemical environments.

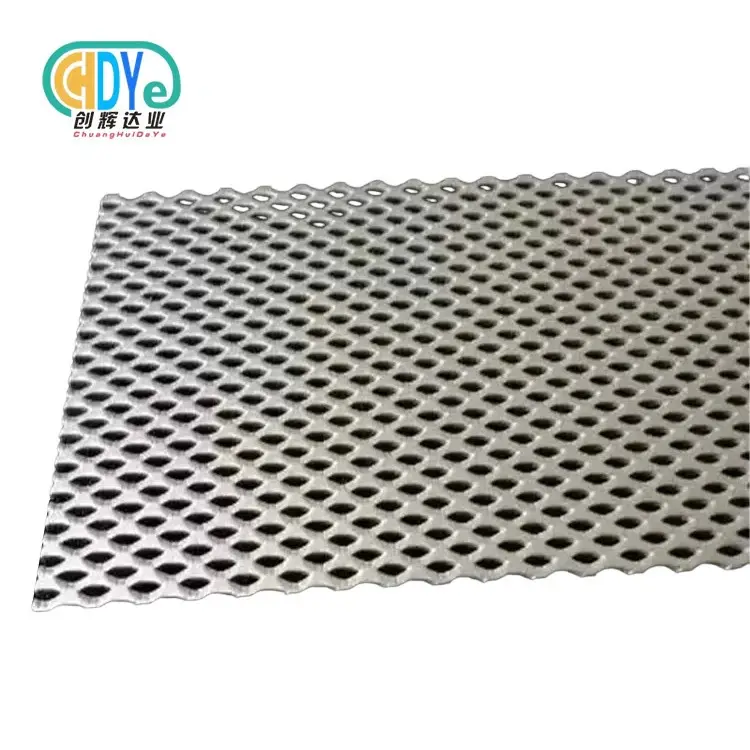

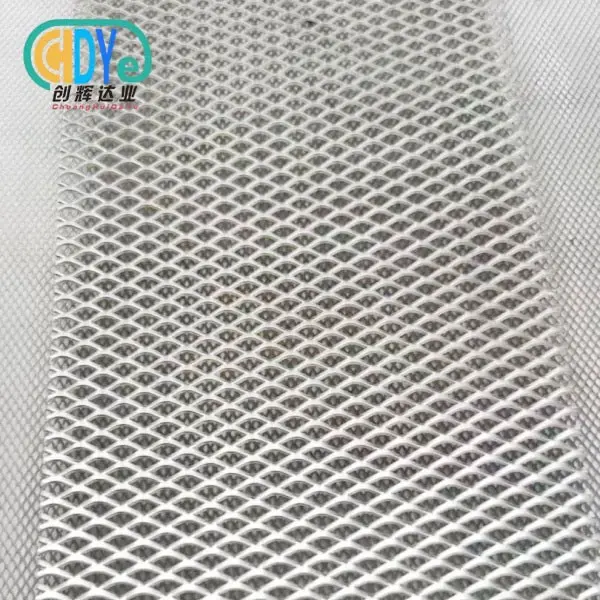

Our Gr2 titanium mesh is widely used in electroplating, chemical processing, seawater desalination, filtration, and aerospace applications. Available in woven, perforated, and expanded formats, it provides versatile solutions for both standard and custom requirements.

Gr2 Titanium mesh is a mesh structure made of pure titanium grade2, which has high strength, good biocompatibility, corrosion resistance, and excellent mechanical properties. It is widely used for screening, filtering, gas and liquid filtration, and separation of other media under various acidic and alkaline environmental conditions.

Technical Specifications

| Property | Specification | Description |

|---|---|---|

| Material Grade | Ti Gr2 | Commercially pure titanium |

| Standards | ASTM B265, ISO 9001, GB/T 3620 | Global quality compliance |

| Mesh Type | Woven / Expanded / Perforated | Customizable per application |

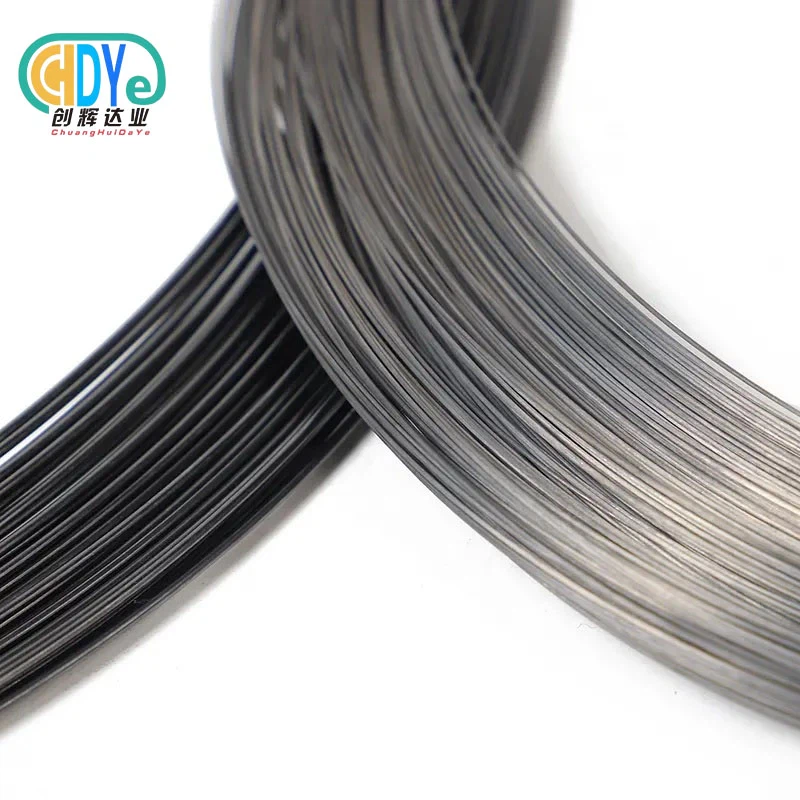

| Wire Diameter | 0.1 – 2.0 mm | ±0.02 mm tolerance |

| Mesh Opening | 0.05 – 10 mm | Adjustable based on process needs |

| Sheet Size | 100×100 mm – 1000×2000 mm | Custom sizes available |

| Thickness | 0.1 – 5 mm | Optional for strength requirements |

| Surface Finish | Pickled, polished, passivated | Optional anodized coating |

| Working Temperature | -250°C to +400°C | High thermal stability |

Gr2 Titanium Mesh Precautions

1. Ensure that the titanium mesh is dry and clean before use to ensure its performance.

2. The appearance of the titanium mesh should be flat, without defects such as cracks, deformations, burrs, etc., to ensure the filtering effect of the titanium mesh.

3. Suitable processing equipment and tools should be used during titanium mesh processing, and standardized operations should be carried out to avoid damaging the titanium mesh.

4. Titanium mesh should avoid contact with chemicals to prevent corrosion, discoloration, and other issues.

5. Titanium mesh should be stored in a dry, ventilated, and dark environment to avoid moisture or exposure to sunlight.

6. When using titanium mesh, attention should be paid to the appropriate working temperature and pressure range to avoid deformation or damage caused by excessive temperature or pressure.

7. After use, titanium mesh should be cleaned, dried, and stored in a timely manner for future use.

Titanium mesh type

Product Features

-

Excellent Corrosion Resistance: Titanium Grade 2 withstands acids, alkalis, and seawater, ensuring long-term durability.

-

High Strength-to-Weight Ratio: Provides superior rigidity while remaining lightweight for handling.

-

Thermal Stability: Maintains structure under extreme temperatures.

-

Biocompatible & Non-Toxic: Suitable for medical, food, and laboratory applications.

-

Customizable Design: Mesh type, wire diameter, and sheet size tailored to your needs.

-

Eco-Friendly: Fully recyclable, non-magnetic, and safe for environmentally sensitive processes.

Applications

Gr2 Titanium Mesh is utilized across a wide range of industries, including:

-

Electroplating & Metal Finishing: As support mesh or basket material in plating baths for nickel, copper, gold, and rhodium.

-

Chemical & Petrochemical Processing: Catalyst supports, filtration grids, and separators for aggressive chemicals.

-

Marine & Offshore Engineering: Desalination, seawater filtration, and cathodic protection.

-

Medical & Laboratory Equipment: Sterilization trays, implants, and high-purity filters.

-

Aerospace & Electronics: Lightweight, corrosion-resistant components for electrical and mechanical assemblies.

-

Environmental Engineering: Gas filtration, wastewater treatment, and chemical recovery systems.

Be used in a wide range of industries.

Marine engineering

Medical implants

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

Shaanxi Chuanghui Daye produces Gr2 titanium mesh with advanced equipment and stringent quality control:

- Wire Drawing & Weaving: Produces uniform, high-strength woven mesh.

- Mesh Expansion: Creates precise perforations or expanded openings without compromising strength.

- Precision Cutting & CNC Forming: Sheet sizes and patterns customized to client specifications.

- Surface Treatment: Pickling, polishing, and optional anodizing for enhanced corrosion resistance.

- MMO or Platinum Coating (Optional): Enhances performance in electrochemical applications.

All production is conducted under ISO 9001:2015 certified procedures, ensuring consistent dimensional accuracy and mesh quality.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Our Gr2 titanium mesh undergoes rigorous quality inspections:

- Chemical composition verification using spectrometer analysis

- Mechanical property testing (tensile strength, elongation)

- Dimensional inspection for mesh size and wire diameter

- Surface integrity checks for scratches, burrs, or oxidation

- Non-destructive testing (NDT) available for critical applications

Each batch is accompanied by a Mill Test Certificate (MTC) to guarantee material authenticity.

Customization & OEM Services

We provide OEM and ODM services to meet diverse industrial and research requirements:

- Mesh opening, wire diameter, and sheet size customization

- Expanded, perforated, or woven mesh fabrication

- Optional surface coating (MMO, platinum, or anodized finish)

- Prototype or small-batch production for R&D

- Engineering consultation for optimized design and performance

Our team ensures that each custom solution meets your exact process requirements with minimal lead time.

Packaging & Global Logistics

- Protective Packaging: Individual sheets wrapped with anti-rust film or kraft paper.

- Secure Transport: Foam-lined crates or export-standard wooden boxes.

- Clear Labeling: Includes grade, mesh size, and batch number for traceability.

- Global Shipping: Sea, air, and express logistics solutions with tracking support.

All packaging ensures safe delivery to over 50 countries and regions.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

Inspection Process

1. Appearance and dimension inspection to ensure every titanium tube meets tolerances,no cracks, pits or other defects on the surface.

2. 100% Straightness inspection.

3. 100% Hydro Testing.

4. Ultrasonic and eddy current testing make sure the product without cracks and scratch.

5. Testing Tensile strength, yield strength by our Tension Tester and the Third party lab to double check the quality.

Why Choose Us

- Over 30 years of experience in titanium and rare metal manufacturing

- Full production control from raw material melting to final inspection

- ISO 9001:2015-certified quality system

- Fast delivery, reliable export, and competitive pricing

- Experienced technical support and one-stop service for titanium mesh solutions

- Trusted by customers across aerospace, chemical, marine, and medical industries

|

|

|

|

|

|

FAQs

Q: What kind of mesh hole do you have?

A: -Common mesh hole size is 3*4mm, 4*8mm 5*10mm,6.5*12.5mm,7*13mm

Q: what's your delivey time?

A: Normal need about 3-5 days if we have in stock. Customized need about 7-10 days

Q: Do you have titanium mesh in stock?

A: yes, normal mesh hole size we have in stock and can cut into your required size.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email