- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

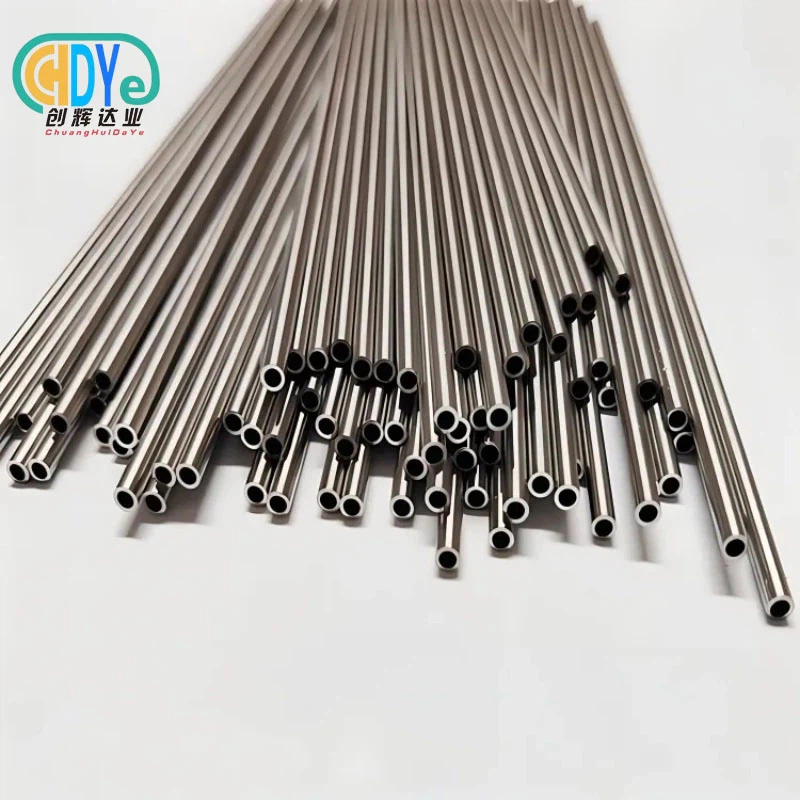

High Purity Tungsten Pipe

Color: metal color

Model Number: W1 W2 WAL1 WAL2

Product Introduction

The High Purity Tungsten Pipe from Shaanxi Chuanghui Daye Metal Material Co., Ltd. is designed for demanding industrial, scientific, and high-temperature applications. Made from ultra-high purity tungsten, this pipe exhibits exceptional thermal stability, outstanding mechanical strength, and superior resistance to oxidation and corrosion. Its precise manufacturing ensures uniform wall thickness, a smooth internal surface, and structural integrity suitable for vacuum systems, metallurgical processes, and high-temperature furnaces.

Certified under ASTM, AMS, ISO, and GB standards, the High Purity Tungsten Tube is ideal for applications that require reliability and long-term durability in extreme conditions. With its seamless design, this pipe minimizes weak points and ensures optimal performance across diverse industries.

Specifications

|

Product Name |

High Purity Tungsten Pipe |

|

Material |

99.95% tungsten |

|

Surface |

Rolling,Black,Alkali wash,Polished,Ground, |

|

Technology |

Sintered |

|

Density |

19.3g/cm3 |

|

Dimension |

OD:6.00-300.00mm,WT:0.2-10mm,Length:≤600mm |

|

Size |

According to your requirements |

|

Melting point |

3410℃ |

Other related tungsten products

tungsten bar, tungsten rod

tungsten plate, tungsten sheet

tungsten wire

other tungsten macined products like crucible, boat ect.

Application Advantages

The High Purity Tungsten Pipe is widely applied in industries that demand high-performance materials:

- Electronics and Semiconductors: Utilized in vacuum chambers, sputtering targets, and high-temperature semiconductor production.

- Aerospace and Defense: Suitable for components in aerospace engines, propulsion systems, and defense equipment requiring high mechanical strength.

- Metallurgy: Used in high-temperature crucibles, molten metal handling, and refractory processes due to excellent thermal properties.

- Scientific Research: Ideal for laboratories conducting high-temperature experiments, vacuum studies, and material science research.

- Energy and Environmental Engineering: Applied in reactors, heat exchangers, and other systems requiring long-term corrosion and heat resistance.

Be used in a wide range of industries.

Steel industry

Electronic devices

Furnace components

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

1.Moulding process: the density of the press block made by powder compacting is the 60~65% of theoretical density.

2.Presintering: under the temperature of 1200℃, the blank is put into hydrogen molybdenum wire furnace for 120min. After cooling to 250℃, move it away. After a presintering process can eliminate most of the adsorbed gas, thereby increasing the strength of th eproduct, which is conducive to the transport and the follow-up processes of sintered tungsten rod.

3.Vacuum sintering: sintering purpose is to increasing the purity and density, a sintering is a process of diffusing. Sintering temperature, atmosphere and holding time are the three main factors that affect the final product quality. If the product can be kept at 1650 ~ 1700℃, the metal impurities and gap elements would volatilize.

4. Cold processing: Cold processing of tungsten alloy pipes after hot processing, such as cold rolling, cold drawing, cold extrusion, etc., to improve their accuracy and surface quality.

5. Heat treatment: Heat treatment is performed on tungsten alloy pipes after cold processing to eliminate internal stress and improve their performance.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Shaanxi Chuanghui Daye implements strict quality control for every High Purity Tungsten Pipe:

- Chemical Composition Analysis: Verifies tungsten purity and alloy composition.

- Dimensional Accuracy Testing: Checks inner and outer diameters and wall thickness tolerances.

- Mechanical and Thermal Testing: Confirms performance under high temperatures and mechanical stress.

- Surface Examination: Detects cracks, roughness, or surface irregularities.

- Traceability: Each pipe is labeled with batch numbers and product specifications for full quality tracking.

These measures ensure consistent reliability and long-term performance.

R&D and Customization

The company offers full R&D support and customization for High Purity Tungsten Pipe:

- Custom Dimensions: Diameters, lengths, and wall thicknesses tailored to specific operational requirements.

- Prototype & Small-Batch Production: Supports R&D projects and specialized industrial applications.

- Material Selection Guidance: Expert consultation for alloying, corrosion resistance, and thermal management.

- Design Optimization: Improvements for increased mechanical strength, thermal conductivity, and service life.

Clients can receive highly customized pipes optimized for their unique operational needs.

Packaging & Global Logistics

Every High Purity Tungsten Pipe is packaged to ensure safe international delivery:

- Wrapped in vacuum or anti-rust films to prevent oxidation.

- Foam padding and reinforced wooden crates protect the pipe during transit.

- Clear labeling with batch numbers, specifications, and handling instructions.

- Shipping via air, sea, or land logistics to over 50 countries including the USA, Germany, France, South Korea, and Singapore.

This ensures that the pipe arrives ready for immediate use.

|

|

|

|

|

|

|

|

|

|

|

|

OEM & Customization Service

Chuanghui Daye provides OEM and customization services for High Purity Tungsten Pipe:

- Custom diameters, lengths, and wall thicknesses according to client specifications.

- Prototype or small-batch production for R&D and specialized industrial applications.

- Technical consultation on material choice, thermal optimization, and performance enhancement.

- Comprehensive after-sales support to guarantee long-term reliability.

These services allow for pipes tailored to even the most demanding operational requirements.

Inspection Process

Each High Purity Tungsten Pipe undergoes a meticulous inspection process:

- Raw Material Verification: Confirms high-purity tungsten and correct alloy ratios.

- Dimensional Check: Ensures precise diameters, wall thickness, and tolerances.

- Mechanical & Thermal Testing: Validates performance under extreme conditions.

- Surface Quality Examination: Detects micro-cracks, imperfections, and roughness.

- Final Approval & Packaging: Ensures the pipe is ready for shipping and application.

This process guarantees quality, durability, and consistent performance.

Why Choose Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd. is a trusted global supplier of tungsten and rare metal products:

- Over 30 years of expertise in high-purity tungsten and refractory metals.

- ISO 9001:2015 certified quality management system.

- Advanced equipment including electron beam furnaces, CNC machines, and precision rolling facilities.

- Products exported to more than 50 countries worldwide.

- Comprehensive OEM and technical support services.

- Commitment to on-time delivery, competitive pricing, and premium quality.

|

|

|

|

|

|

FAQs

Q1: What material is used in the pipe?

A1: Ultra-high purity tungsten and tungsten alloys are used to ensure exceptional mechanical, thermal, and chemical properties.

Q2: Can the pipe be customized?

A2: Yes, clients can request specific diameters, lengths, and wall thicknesses for specialized applications.

Q3: Which industries typically use these pipes?

A3: Electronics, aerospace, defense, metallurgy, energy, and scientific research.

Q4: How is the pipe packaged for international shipment?

A4: Wrapped in vacuum or anti-rust films, padded with foam, and shipped in reinforced wooden crates.

Q5: Do you provide technical support for material selection?

A5: Yes, our experts provide guidance on alloy choice, thermal optimization, and design improvements.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email