- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

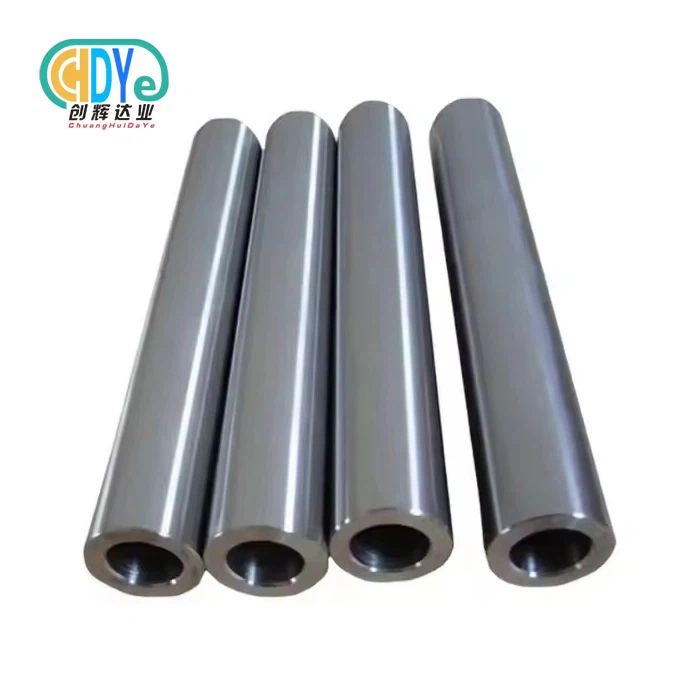

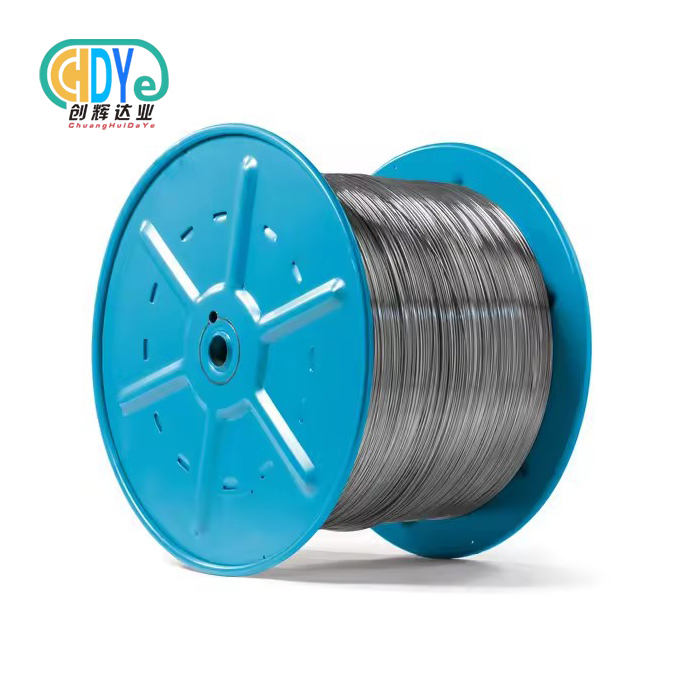

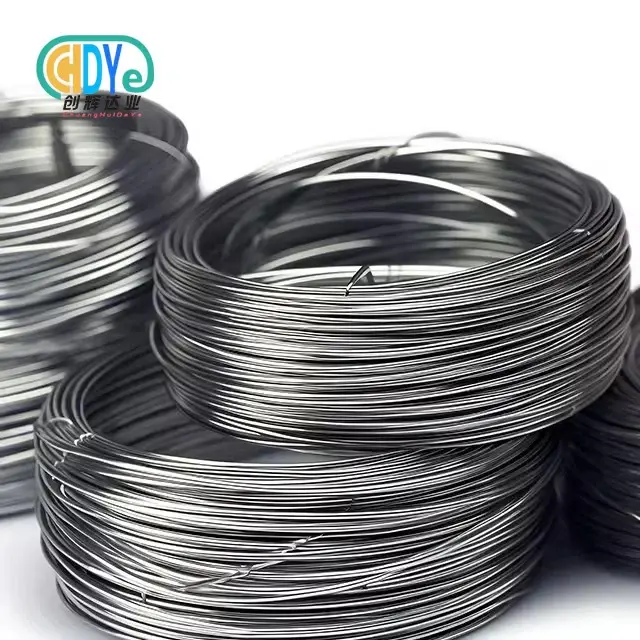

Titanium Wire For Sale

2.Diameter range:0.3-8mm

3.Surface treatment:bright, pickled, polished (customizable according to needs)

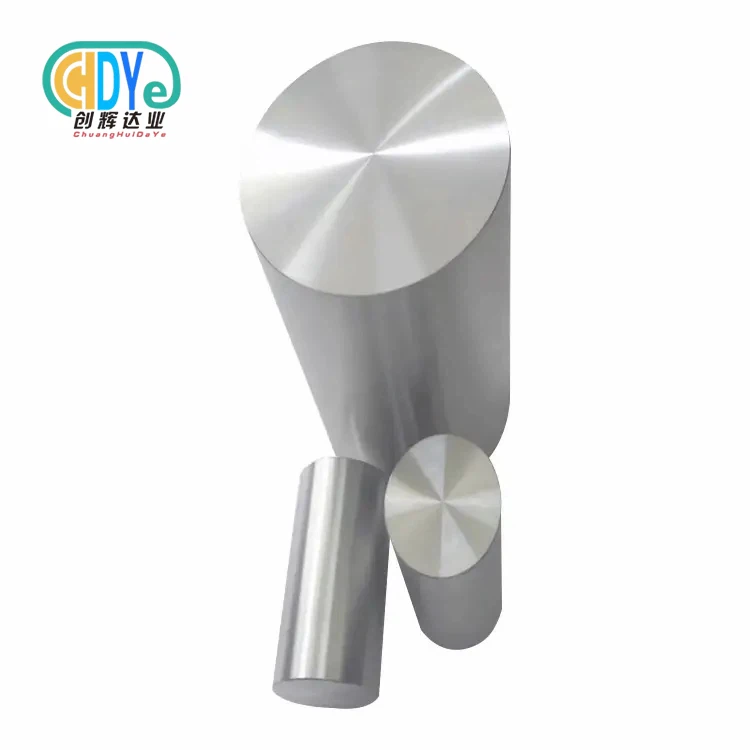

Product Overview

Titanium Wire For Sale from Shaanxi Chuanghui Daye Metal Material Co., Ltd. is designed for customers seeking high-performance materials with excellent strength, corrosion resistance, and stability across demanding environments. Produced in Baoji—the heart of China’s “Titanium Valley”—our titanium wires are crafted using advanced melting, drawing, and annealing technologies to ensure superior dimensional accuracy and mechanical integrity.

We supply titanium wire in various grades including Gr1, Gr2, Gr5, Gr7, Gr9, and Gr12, covering both pure titanium and titanium alloy compositions. Whether for welding, medical use, or industrial fabrication, our wires deliver consistent performance that meets or exceeds ASTM, AMS, ISO, and GB standards.

Titanium wire for sale made of high-purity titanium material with excellent strength, corrosion resistance and biocompatibility. It is suitable for a variety of industries such as aerospace, medical equipment, chemicals, automobile manufacturing and high-end consumer goods. Chdymetal offer titanium wire for sale with best price and good quality.

Standard: ASTM B863

Diameter range: 0.3-8mm

Shape: Round

Type: coil, straight

Surface treatment: bright, pickled, polished (customizable according to needs)

Technical Specifications

| Parameter | Description |

|---|---|

| Material Grade | Gr1, Gr2, Gr3, Gr4, Gr5 (Ti-6Al-4V), Gr7, Gr9, Gr12 |

| Standard | ASTM B863 / AMS 4951 / ISO 5832-2 |

| Diameter Range | 0.1 mm – 8.0 mm |

| Surface Finish | Bright, pickled, polished, or sand-blasted |

| Tolerance | ±0.01 mm – ±0.05 mm |

| Density | 4.51 g/cm³ |

| Tensile Strength | 240–950 MPa (depending on grade) |

| Elongation | 10%–30% |

| Condition | Annealed / Straightened / Cold drawn / Coil |

| Packaging | Spool, coil, or cut length (customized) |

Product Features & Advantages

-

Exceptional Corrosion Resistance

Titanium wire offers unparalleled resistance to seawater, acid, and alkali environments, making it ideal for marine and chemical industries. -

Outstanding Strength-to-Weight Ratio

With a density 45% lower than steel but similar strength, it ensures lightweight efficiency in aerospace and medical applications. -

Excellent Weldability and Ductility

Manufactured with precise control over microstructure, our wires maintain excellent weldability and formability for all fabrication processes. -

High Temperature Stability

Retains mechanical performance up to 600°C, suitable for high-heat industrial and aerospace environments. -

Ultra-Clean Surface Quality

Processed with multi-stage acid pickling and polishing to remove oxide scales and impurities, ensuring consistent conductivity and reliability. -

Precision Dimensional Control

Each batch is subject to laser measurement and tensile testing to guarantee tight tolerance and consistent wire diameter.

Manufacturing Process

Our titanium wire manufacturing integrates strict process control and modern metallurgy principles:

-

Vacuum Melting & Refining – Raw titanium sponge is melted in a vacuum arc furnace to ensure purity and uniformity.

-

Forging & Hot Rolling – Ingots are shaped into billets and rolled into precise wire rods.

-

Pickling & Descaling – Surface oxides are removed to maintain chemical stability.

-

Cold Drawing – Multi-pass drawing ensures smooth surface and exact dimensions.

-

Heat Treatment & Annealing – Stress relief and improved ductility for further forming or welding.

-

Straightening & Cutting – Optional coil or straight wire form according to customer specifications.

-

Inspection & Packaging – 100% visual and dimensional checks prior to shipment.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Quality is at the core of Chuanghui Daye’s operation. We strictly follow ISO 9001:2015 standards and perform comprehensive testing throughout production:

- Chemical Composition Analysis (Spectrometer)

- Mechanical Testing (Tensile, Hardness, Elongation)

- Dimensional Accuracy Verification

- Surface Roughness & Cleanliness Test

- Ultrasonic & Eddy Current Inspection

All test results are documented and traceable by batch number, ensuring full quality assurance for every shipment.

Application Advantages

Our Titanium Wire For Sale serves a wide range of sectors that demand reliability and performance under extreme conditions:

- Aerospace & Defense: for control cables, fasteners, and spring components

- Medical & Dental: surgical instruments, orthopedic implants, and dental brackets

- Chemical Processing: electrode and anode wire, reactor components

- Marine Engineering: seawater-resistant nets, springs, and fixtures

- Electronics: lead wires for capacitors and high-purity connections

- Automotive & Racing: high-performance exhaust and suspension parts

- Energy & Environment: used in fuel cells, anodes, and heat exchangers

Be used in a wide range of industries.

Marine engineering

Medical implants

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

OEM & Customization Service

We provide OEM/ODM solutions tailored to your requirements:

- Custom diameters, shapes, and coil sizes

- Special alloy compositions and heat treatments

- Precision winding for medical or aerospace use

- Third-party inspection (SGS, BV, TUV) available upon request

- Full export documentation support (CO, Form E, etc.)

Packaging & Global Logistics

Packaging: moisture-proof and shock-proof packaging to ensure that the product is not damaged during transportation.

Delivery method: support sea transportation, air transportation and express delivery, and provide global delivery services.

Delivery time: 7-15 days for conventional products, customized products are negotiated according to demand

ASTM B863 titanium wire Quality Assurance

Each batch of products comes with a material certificate (MTC)

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

Why Choose Us

1.You can get the quick response from sales person,usually within 2 hours.

2. We offer economical door to door shipping cost like FEDEX, DHL, UPS and so on.

3. The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.

5. You can get stock alternatives, mill deliveries with minimizing manufacturing time.

|

|

|

|

|

|

FAQ

Q1: What is the difference between pure titanium and titanium alloy wire?

A1: Pure titanium wire (Gr1–Gr4) offers excellent corrosion resistance and flexibility, while alloy wire (Gr5, Gr9, etc.) provides higher strength and temperature resistance.

Q2: Can you produce ultra-fine titanium wire below 0.3 mm?

A2: Yes, we can produce precision wire down to 0.1 mm diameter with tight tolerances for electronic or medical applications.

Q3: Do you supply titanium wire in spool or straight form?

A3: Both options are available—coil/spool for continuous welding use, or straight-cut wire for precision assembly.

Q4: How do you ensure consistent wire quality?

A4: Each batch undergoes full mechanical, chemical, and surface inspection with ISO 9001 traceability.

Q5: Can you provide small quantity samples?

A5: Yes, we support sample orders for testing or prototype development before bulk purchasing.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email