When comparing Gr2 titanium pipe with stainless steel for industrial applications, several key performance differences emerge. Gr2 titanium pipes demonstrate superior corrosion resistance in aggressive environments, particularly against chlorides and acids. Stainless steel offers higher strength and cost-effectiveness for general applications. The choice between these materials depends on specific operational requirements including environmental conditions, mechanical demands, and budget considerations. Understanding these performance characteristics helps engineers select the optimal piping solution for their projects.

Core Material Properties: Understanding the Fundamental Differences

The principal characteristics of Gr2 titanium and stainless steel make unmistakable execution profiles. Review 2 titanium shows remarkable erosion resistance through its actually shaped oxide layer. This defensive boundary recovers naturally when harmed, giving steady protection.

Stainless steel infers its erosion resistance from chromium substance, regularly 10.5% least. The chromium shapes a inactive layer that ensures the fundamental fabric. Be that as it may, this security can break down beneath particular conditions.

Three center fabric contrasts include:

- Density: Titanium (4.51 g/cm³) vs Stainless Steel (7.9-8.1 g/cm³)

- Melting Point: Titanium (1,668°C) vs Stainless Steel (1,400-1,530°C)

- Thermal Conductivity: Titanium (16.4 W/m·K) vs Stainless Steel (14-16 W/m·K)

These properties specifically affect execution in mechanical applications. The lower thickness of titanium makes noteworthy weight points of interest in aviation and marine applications. In the interim, the higher dissolving point gives improved warm stability.

If you require lightweight channeling frameworks for aviation or marine applications, at that point titanium amalgam pipe gets to be the favored choice. For common mechanical applications where weight is not basic, stainless steel offers satisfactory execution at lower cost.

Corrosion Resistance Analysis: Real-World Performance Data

Corrosion resistance speaks to the most critical execution differentiator between these materials. Research facility testing uncovers significant contrasts in different environments.

In seawater introduction tests, review 2 titanium tubing appeared for all intents and purposes no erosion after 10 a long time of nonstop introduction. The erosion rate measured less than 0.0025 mm/year. Stainless steel 316L illustrated great execution with erosion rates of 0.025-0.05 mm/year beneath comparative conditions.

Chemical resistance testing appears indeed more sensational differences:

- Hydrochloric corrosive (10%): Titanium appears irrelevant assault, whereas 316L stainless steel encounters critical corrosion

- Sulfuric corrosive (concentrated): Titanium remains steady, stainless steel requires higher combination grades

- Chloride situations: Titanium illustrates total resistance to setting and hole corrosion

The prevalent execution stems from titanium's capacity to keep up its defensive oxide layer. This layer changes right away when harmed, giving nonstop assurance. Stainless steel can encounter localized erosion when the inactive layer breaks down.

If you require channeling for chemical handling or marine situations, then gr2 titanium pipe erosion resistance gives unmatched unwavering quality. For less forceful situations like nourishment preparing or pharmaceutical applications, high-grade stainless steel offers adequate protection.

Mechanical Properties and Strength Comparison

Mechanical properties decide basic execution beneath different stacking conditions. Both materials offer particular preferences depending on application requirements.

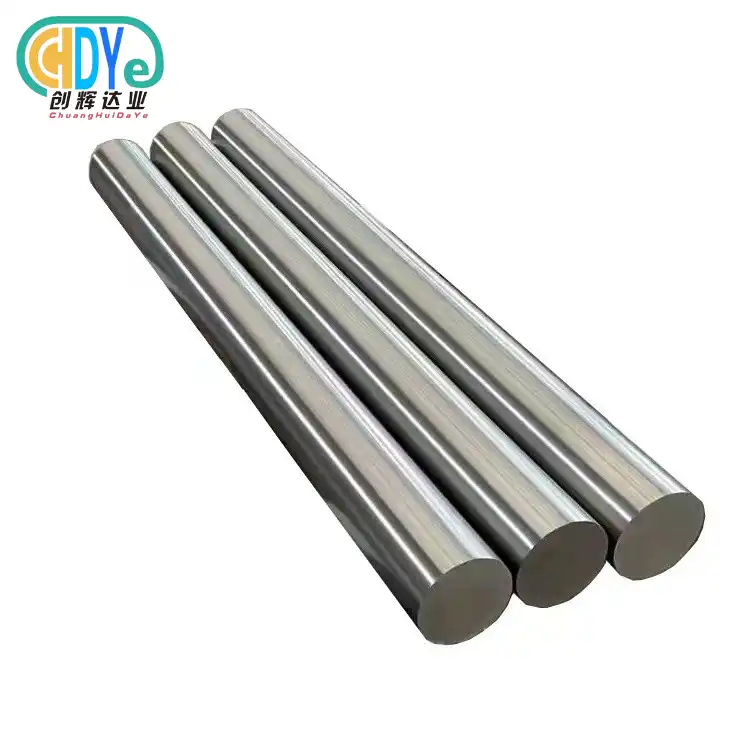

Grade 2 titanium gives great strength-to-weight proportion characteristics. Pliable quality ranges from 345-485 MPa, with abdicate quality of 275-410 MPa. The fabric keeps up ductility with prolongation values of 20% minimum.

Stainless steel 316L offers higher supreme quality values. Ductile quality comes to 485-620 MPa, with surrender quality of 170-310 MPa. The fabric illustrates great ductility with stretching values of 40% minimum.

Key mechanical execution variables include:

- Fatigue resistance: Titanium appears prevalent execution in cyclic loading

- Impact resistance: Both materials give great sturdiness at surrounding temperatures

- High-temperature quality: Titanium keeps up properties superior at raised temperatures

- Low-temperature execution: Both materials stay pliable at sub-zero temperatures

The modulus of versatility contrasts essentially between materials. Titanium measures 103-107 GPa, whereas stainless steel comes to 200 GPa. This distinction influences diversion characteristics beneath load.

If you require tall supreme quality for weight vessels, at that point stainless steel gives cost-effective execution. For applications requiring ideal strength-to-weight proportions like aviation frameworks, at that gr2 titanium pipe quality conveys prevalent value.

Cost Analysis and Economic Considerations

Economic factors significantly influence material selection decisions. Initial costs, lifecycle expenses, and maintenance requirements create the total ownership picture.

Raw material costs show substantial differences. Stainless steel 316L typically costs $3-5 per kilogram, while Grade 2 titanium ranges from $15-25 per kilogram. However, titanium's lower density reduces the weight-based cost differential.

Processing and fabrication costs also vary between materials. Stainless steel benefits from established manufacturing processes and widespread supplier networks. Titanium pipe manufacturers require specialized equipment and expertise, increasing fabrication costs.

Lifecycle cost considerations include:

- Maintenance frequency: Titanium requires minimal maintenance in corrosive environments

- Replacement intervals: Extended service life of titanium reduces replacement costs

- System weight: Lower weight reduces structural support requirements

- Operational efficiency: Corrosion resistance maintains flow characteristics longer

Long-term economic analysis often favors titanium in demanding applications. Reduced maintenance, extended service life, and improved reliability offset higher initial costs.

If you need immediate cost savings for standard applications, then stainless steel provides excellent value. For critical applications where downtime costs exceed material premiums, then investing in titanium seamless pipe delivers superior long-term economics.

Manufacturing and Processing Capabilities

Manufacturing processes significantly impact material performance and cost. Both materials require different approaches for optimal results.

Stainless steel benefits from mature manufacturing technologies. Hot forming, cold working, and welding processes are well-established. Standard equipment handles most fabrication requirements without specialized modifications.

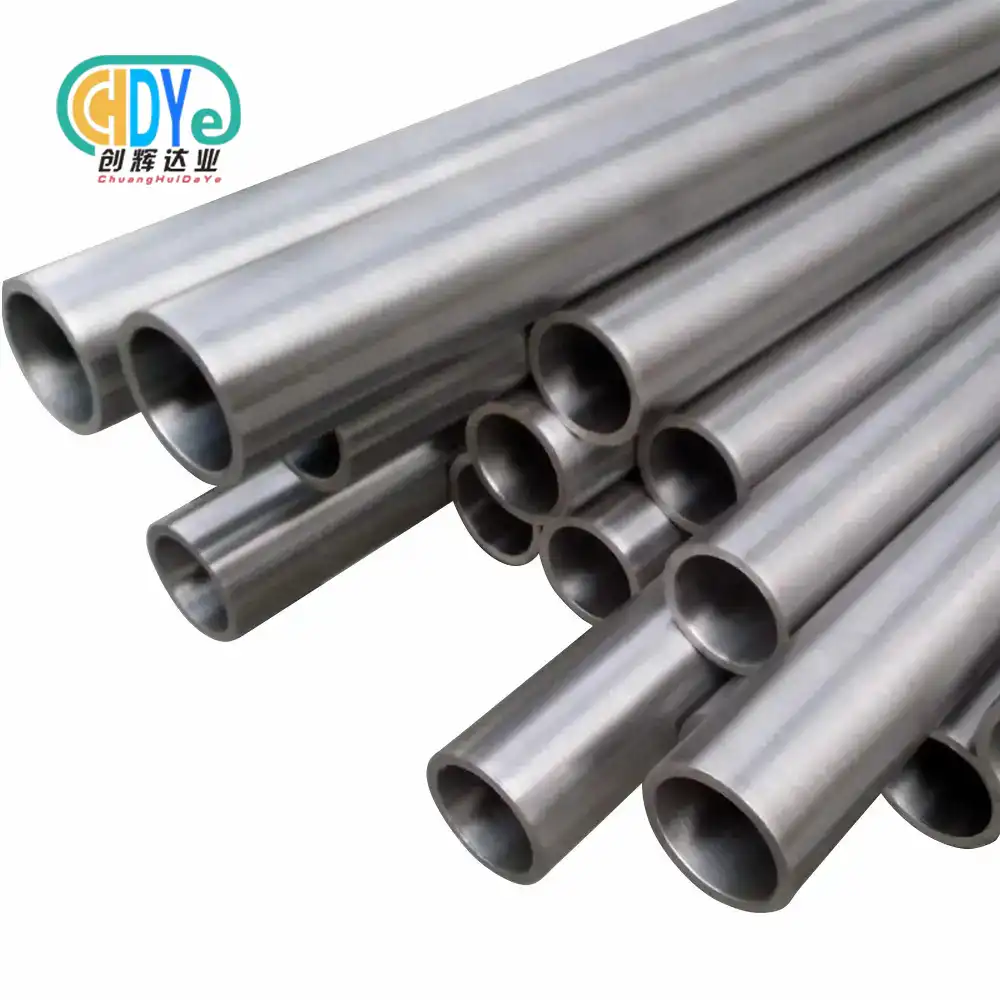

Titanium processing demands more sophisticated approaches. Controlled atmosphere welding prevents contamination. Titanium pipe welding requires inert gas protection and specialized techniques. Heat treatment must occur in vacuum or inert atmospheres.

Machining characteristics differ substantially between materials. Titanium requires slower cutting speeds and specialized tooling. The material's tendency to work-harden demands careful attention to cutting parameters.

Processing considerations include:

- Welding requirements: Titanium needs inert atmosphere protection

- Forming capabilities: Both materials offer good formability with proper techniques

- Heat treatment: Titanium requires controlled atmosphere processing

- Surface finishing: Both materials achieve excellent surface quality

Quality control requirements are more stringent for titanium applications. Contamination from iron, oxygen, or hydrogen can significantly impact properties. Titanium pipe specifications demand careful attention to cleanliness throughout processing.

If you need straightforward fabrication with standard equipment, then stainless steel provides manufacturing advantages. For applications requiring ultimate performance where processing complexity is acceptable, then titanium delivers unmatched capabilities.

Application-Specific Performance Requirements

Different industries prioritize various performance characteristics. Understanding these requirements guides optimal material selection.

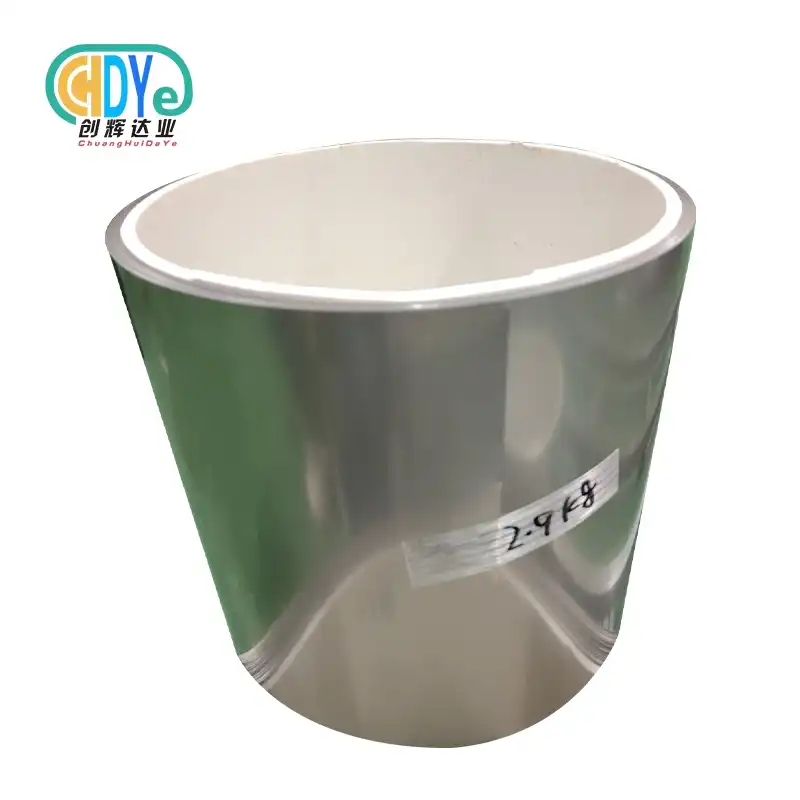

Chemical processing applications demand exceptional corrosion resistance. Titanium pipe applications in this sector include heat exchangers, reaction vessels, and process piping. The material's immunity to chloride stress corrosion cracking provides crucial safety margins.

Aerospace applications prioritize weight reduction and reliability. Titanium pipe for aerospace systems includes hydraulic lines, fuel systems, and air conditioning. The material's strength-to-weight ratio enables significant weight savings.

Medical applications require biocompatibility and corrosion resistance. Titanium pipe for medical use includes surgical instruments, implant components, and hospital equipment. The material's non-toxic properties ensure patient safety.

Industry-specific advantages include:

- Marine: Complete immunity to seawater corrosion

- Chemical: Resistance to aggressive acids and chlorides

- Aerospace: Superior strength-to-weight performance

- Medical: Excellent biocompatibility and cleanliness

Power generation applications benefit from titanium's thermal stability. Condenser tubing in both nuclear and fossil plants demonstrates extended service life. The material maintains integrity under thermal cycling conditions.

If you need proven performance in standard industrial applications, then stainless steel offers reliable service. For critical applications where failure consequences are severe, then titanium pipe fittings provide unmatched reliability and safety margins.

Quality Standards and Certification Requirements

Industry standards ensure consistent material performance across applications. Both materials comply with rigorous certification requirements.

Titanium pipe ASTM standards include ASTM B861 for seamless pipe and ASTM B862 for welded pipe. These specifications define chemical composition, mechanical properties, and dimensional tolerances. Additional standards like ASME SB-861 provide pressure vessel requirements.

Stainless steel follows ASTM A312 for seamless and welded austenitic pipe. ASME SA-312 provides equivalent requirements for pressure applications. These standards ensure consistent quality across suppliers.

Quality management systems provide additional assurance. ISO 9001:2015 certification demonstrates systematic quality control. Advanced suppliers implement aerospace standards like AS9100 for critical applications.

Certification benefits include:

- Traceability: Complete material history documentation

- Testing verification: Mechanical and chemical property confirmation

- Process control: Consistent manufacturing procedures

- Customer confidence: Third-party validation of quality systems

Material test reports provide detailed property verification. Certified suppliers conduct tensile testing, chemical analysis, and dimensional inspection. This documentation ensures compliance with project specifications.

If you need standard compliance for general applications, then certified stainless steel provides adequate assurance. For aerospace, medical, or chemical applications requiring ultimate reliability, then certified titanium tube suppliers deliver the highest quality standards.

Chuanghui Daye's Gr2 Titanium Pipe Advantages

Shaanxi Chuanghui Daye Metal Material Co., Ltd. delivers exceptional gr2 titanium pipe solutions backed by three decades of industry expertise. Our advantages include:

- Strategic Location: Located in Baoji High-tech Development Zone, China's "Titanium Capital," providing access to premium raw materials and established supply chains

- Advanced Manufacturing: State-of-the-art facilities including electron beam furnaces, precision rolling machines, and controlled atmosphere processing equipment

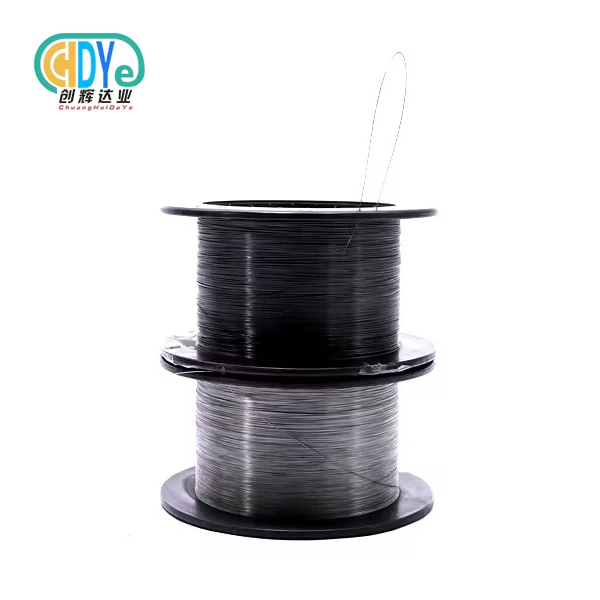

- Comprehensive Product Range: Seamless and welded titanium pipes from Gr1 through Gr23, with custom dimensions and specifications

- Quality Assurance: ISO 9001:2015 certified quality management system ensuring consistent production standards

- Technical Expertise: Engineering support for material selection, fabrication guidance, and application-specific solutions

- Global Compliance: Products meet ASTM B861, ASTM B337, ASME SB338 standards for worldwide compatibility

- Flexible Production: Capabilities for both large-scale production and small-batch prototyping

Performance Summary and Selection Guidelines

| Property | Gr2 Titanium Pipe | Stainless Steel 316L |

|---|---|---|

| Corrosion Resistance | Excellent in all environments | Good in most environments |

| Strength-to-Weight Ratio | Superior (76-107 kN·m/kg) | Good (61-78 kN·m/kg) |

| Initial Cost | Higher | Lower |

| Lifecycle Cost | Lower in demanding applications | Lower in standard applications |

| Fabrication Complexity | Requires specialized techniques | Standard fabrication methods |

| Temperature Performance | Excellent up to 300°C | Good up to 870°C |

Material selection requires careful evaluation of operational requirements, environmental conditions, and economic factors. The decision matrix should weigh initial costs against lifecycle performance benefits.

Selection guidelines include:

- Choose titanium for marine, chemical, and aerospace applications

- Select stainless steel for food processing and general industrial use

- Consider titanium, where weight reduction provides system benefits

- Evaluatethe total cost of ownership, including maintenance and replacement

Both materials offer distinct advantages in appropriate applications. Understanding these performance characteristics enables optimal material selection for specific project requirements.

Conclusion

The comparison between Gr2 titanium pipe and stainless steel reveals distinct performance profiles suited to different applications. Titanium excels in corrosive environments, weight-critical applications, and long-term reliability scenarios. Stainless steel provides cost-effective solutions for standard industrial applications with adequate corrosion resistance.

Material selection depends on specific operational requirements, environmental conditions, and economic considerations. Understanding these performance differences enables engineers to make informed decisions that optimize both performance and cost-effectiveness for their specific applications.

Both materials continue advancing through improved manufacturing processes and alloy development, ensuring reliable solutions for demanding industrial applications worldwide.

Partner with Chuanghui Daye for Premium Gr2 Titanium Pipe Solutions

Chuanghui Daye stands ready to deliver exceptional Gr2 titanium pipe solutions tailored to your specific requirements. Our ISO 9001:2015 certified facility combines advanced manufacturing capabilities with comprehensive quality assurance. Whether you need standard dimensions or custom-fabricated components, our experienced team provides technical expertise and reliable delivery. As a leading Gr2 titanium pipe manufacturer, we offer competitive factory-direct pricing with complete traceability documentation. Transform your project performance with our premium titanium piping solutions, and contact us at info@chdymetal.com.

References

1. Boyer, R., Welsch, G., & Collings, E.W. (1994). Materials Properties Handbook: Titanium Alloys. ASM International, Materials Park, OH.

2. Schutz, R.W. & Thomas, D.E. (1987). Corrosion of titanium and titanium alloys. Metals Handbook, 9th Edition, Volume 13, Corrosion, ASM International.

3. American Society for Testing and Materials. (2019). ASTM B861-19 Standard Specification for Titanium and Titanium Alloy Seamless Pipe. ASTM International, West Conshohocken, PA.

4. Gedge, G. (2008). Structural uses of stainless steel buildings and civil engineering. Journal of Constructional Steel Research, 64(11), 1194-1198.

5. Peters, M., Hemptenmacher, J., Kumpfert, J., & Leyens, C. (2003). Structure and Properties of Titanium and Titanium Alloys. Titanium and Titanium Alloys: Fundamentals and Applications, Wiley-VCH.

6. Sedriks, A.J. (1996). Corrosion of Stainless Steels, 2nd Edition. John Wiley & Sons, New York.