- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Molybdenum Round Bar

Standard : ASTM B387

Technological process:Pressing, Singtering, forging, maching

Product Introduction

The Molybdenum Round Bar supplied by Shaanxi Chuanghui Daye Metal Material Co., Ltd. is produced from high-purity molybdenum powder using advanced sintering, forging, and machining techniques. Known for its exceptional strength, excellent thermal conductivity, and outstanding resistance to heat and corrosion, the Molybdenum Round Rod performs reliably in demanding industrial environments. Each bar meets international standards such as ASTM B387, GB/T 4181, and ISO 9001:2015, ensuring superior density, uniform grain structure, and long service life.

|

Products Name |

Molybdenum round bar |

|

Diameter & Length |

According to your drawings |

|

Grade |

Mo1 |

|

Material |

99.95% Molybdenum |

|

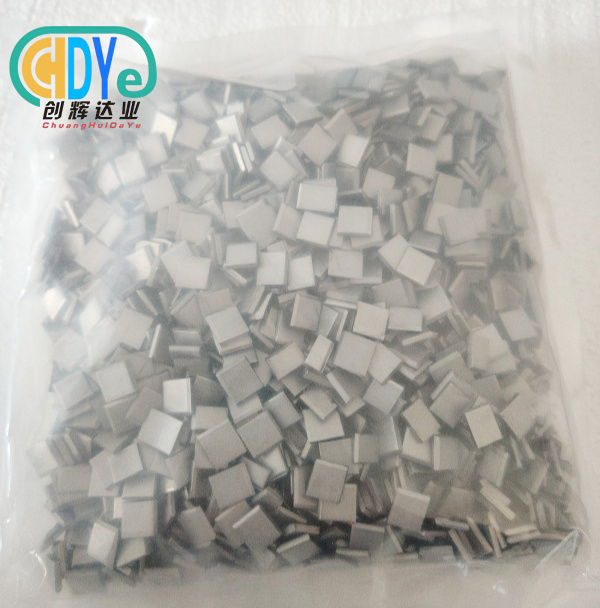

Technological process |

Pressing, Singtering, forging, maching |

|

Application |

Welding Electrode, Lighting, Furnace parts and High temperature alloys, |

Model Number : Mo1

Material : 99.95%

Standard : ASTM B387

Certificate : ISO9001:2015

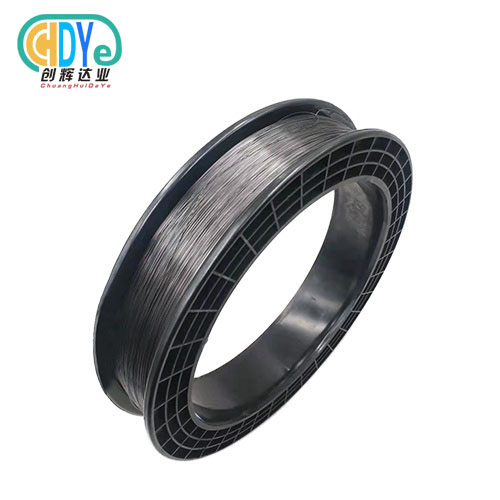

Usage: electrode, Support line, lead-in line, printer needle

Feature : Low thermal expansion and good thermal conductivity

Diameter: Customized

Length: according to your order

melting point: 2320 ℃

Application Advantages

The Molybdenum Round Bar is widely used across various high-tech and industrial sectors, including:

- Aerospace and Defense: Engine components, shielding materials, and structural parts for high-temperature systems.

- Electronics and Semiconductors: Electrodes, heat sinks, and vacuum evaporation sources.

- Metallurgy and Furnace Industry: Shafts, rods, and supports in high-temperature furnaces and glass production.

- Energy and Chemical Engineering: Corrosion-resistant parts for reactors, heaters, and high-pressure equipment.

- Medical and Optical Devices: Precision machined components and X-ray shielding structures.

Be used in a wide range of industries.

Steel industry

Electronic devices

Furnace components

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

1. Spinning molybdenum bar - electric furnace heating - spinning blank - electric furnace heating - spinning - molybdenum rod/molybdenum rod

2. Rolling hole: molybdenum strip - rolling billet - electric furnace heating - three high mill - molybdenum rod/rod

Surface Finish

Black Surface is "as swaged or "as drawn"; Retaining a coating of processing lubricants and oxides.

Cleaned - Surface is chemically cleaned to remove all lubricants and oxides.

Ground - Surface is centerless ground to remove all coating and to achieve precise diameter control.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Strict quality management is implemented throughout production to ensure that each Molybdenum Round Bar meets or exceeds customer expectations:

- Raw Material Testing: Purity, composition, and particle size analysis before production.

- Dimensional and Density Control: Ultrasonic and physical testing to ensure consistency and defect-free quality.

- Mechanical Property Verification: Tensile strength, hardness, and elongation tests.

- Surface Quality Examination: Visual and microscopic inspections ensure a clean, smooth finish.

All quality control procedures comply with ISO 9001:2015 standards for traceability and reliability.

R&D and Customization

With strong R&D capability, Shaanxi Chuanghui Daye continues to innovate in the field of refractory metal processing. Our customization services for Molybdenum Round Bar include:

- Custom diameters ranging from 2 mm to 150 mm.

- Heat treatment and surface finish options (ground, polished, or machined).

- Alloy modifications for improved strength or thermal stability.

- Engineering design support for specialized industrial applications.

Our technical team provides tailored solutions to meet the specific needs of clients in aerospace, medical, and semiconductor industries.

Packaging & Global Logistics

Each Molybdenum Round Bar is securely packaged to ensure safe transportation and delivery worldwide:

- Inner Packaging: Anti-rust or vacuum-sealed film to prevent oxidation.

- Outer Packaging: Strong export-standard wooden cases with foam protection.

- Marking: Each package is labeled with detailed product specifications, grades, and batch numbers.

We cooperate with reliable logistics partners to deliver goods quickly and safely by air, sea, or express courier to over 50 countries including the U.S., Germany, South Korea, and Singapore.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Shaanxi Chuanghui Daye provides flexible OEM and ODM services to meet diverse client requirements:

- Production according to custom drawings and specifications.

- Prototype and small-batch production for R&D projects.

- Surface and mechanical property adjustments based on end-use conditions.

- Private labeling and special packaging for brand distributors.

We ensure cost-effective production, short lead times, and full technical support for every order.

Inspection Process

Each Molybdenum Round Bar undergoes a multi-step inspection process before dispatch:

- Raw Material Verification: Spectral analysis and purity certification.

- Dimensional Check: Measurement of diameter, straightness, and tolerance using precision instruments.

- Ultrasonic Testing: Detection of internal flaws or inclusions.

- Mechanical Performance Test: Verification of density, hardness, and tensile strength.

- Final Review and Packaging: Only qualified products are packaged and shipped with full inspection documentation.

Why Choose Us

- Over 30 Years of Expertise in rare metal manufacturing and processing.

- ISO 9001:2015 Certified for strict quality and production control.

- Advanced Facilities including electron beam furnaces, rolling and forging machines.

- Customized Solutions for high-temperature and precision applications.

- Fast Global Delivery within 7 days for standard sizes.

- Trusted by 50+ Countries with excellent customer satisfaction and reputation.

|

|

|

|

|

|

FAQs

Q1: What is the purity of your Molybdenum Round Bar?

A1: The purity is ≥99.95%, conforming to ASTM B387 and GB/T 4181 standards.

Q2: What diameter ranges are available?

A2: Standard diameters range from 2 mm to 150 mm, with customization available upon request.

Q3: Can you provide special surface finishes?

A3: Yes, we offer polished, ground, or machined finishes depending on customer requirements.

Q4: What industries typically use your molybdenum bars?

A4: They are widely used in aerospace, electronics, metallurgy, chemical processing, and energy industries.

Q5: Do you support OEM services for international clients?

A5: Yes, we offer OEM labeling, custom dimensions, and packaging solutions for distributors and manufacturers.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email