- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

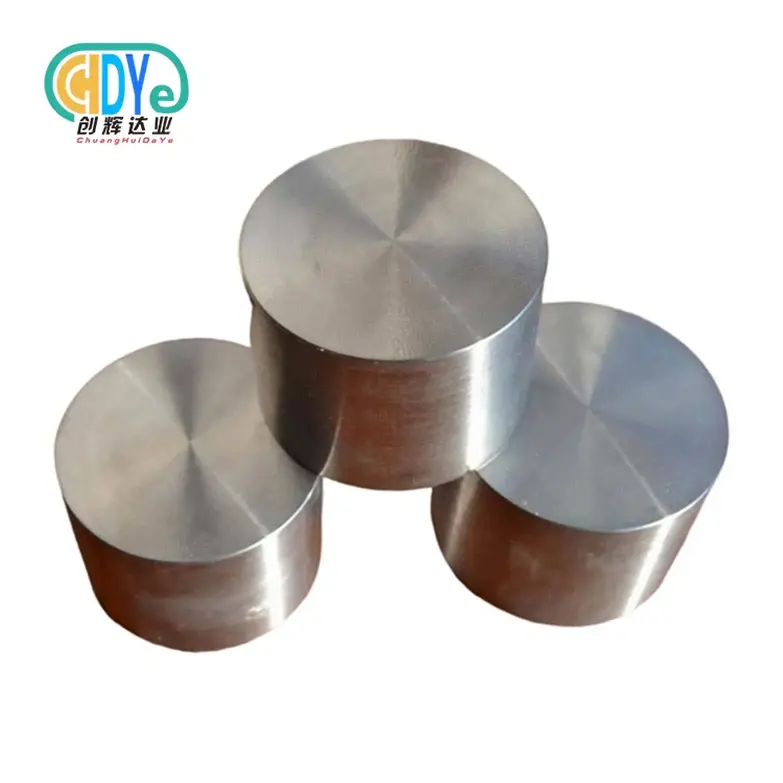

TZM Molybdenum Alloy Rod

2.Certificate: ISO9001:2015

3.Delivery time:10-15 days or as your quantity

Product Introduction

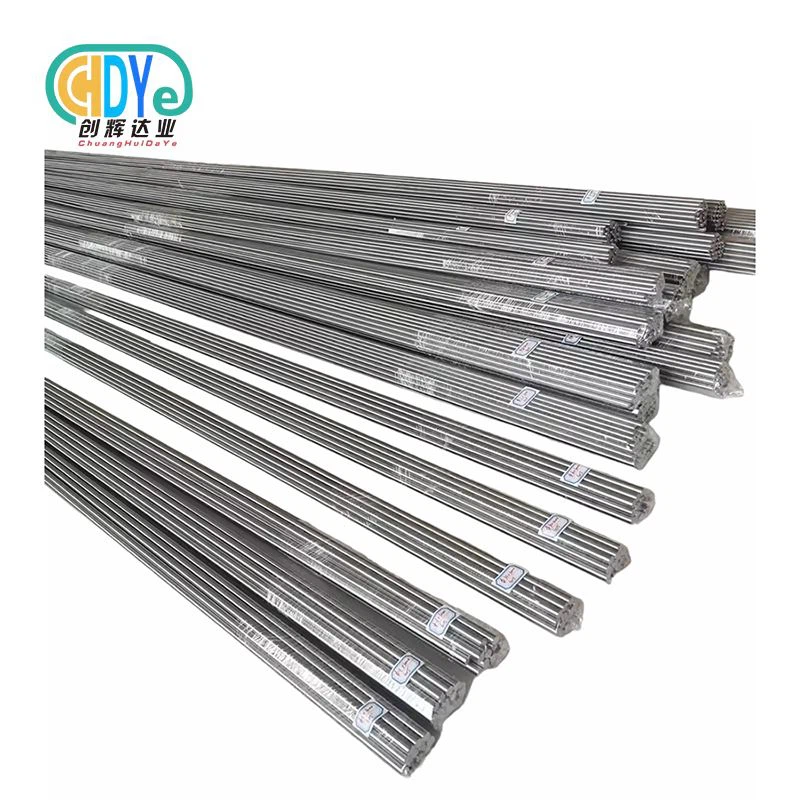

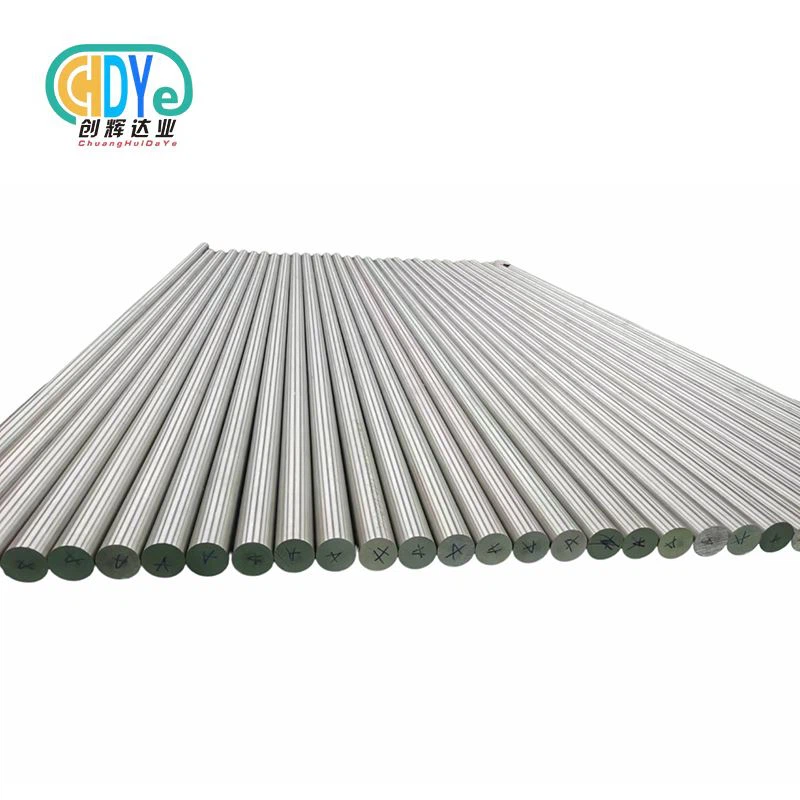

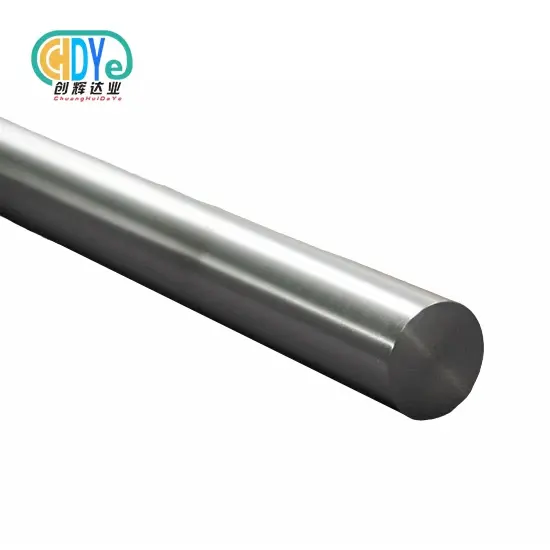

Shaanxi Chuanghui Daye Metal Material Co., Ltd. offers high-performance TZM Molybdenum Alloy Rod designed for applications requiring exceptional strength and thermal stability at elevated temperatures. Alloyed with titanium and zirconium, it provides enhanced creep resistance and mechanical properties. Produced using advanced electron beam melting and precision forging techniques, each rod ensures uniform microstructure, dimensional accuracy, and superior performance.

TZM, an acronym for the molybdenum alloy "titanium-zirconium-molybdenum", is a molybdenum alloy containing 0.5% titanium, 0.08% zirconium, 0.02% carbon and the balance molybdenum. TZM, like pure molybdenum, can be produced by powder metallurgy or arc-cast processes.

Diameter: Dia3-200mm *Length or customized

Surface: Black Ground Polished

Certificate: ISO9001:2015

Delivery time:10-15 days or as your quantity

Chemical Composition

|

Grade |

Chief constituent % |

The impurity content is not more than % |

|||||||||||

|

Mo |

Ti |

Zr |

C |

Al |

Ca |

Fe |

Mg |

Ni |

Si |

C |

N |

O |

|

|

Mo1 |

|

- |

- |

- |

0.002 |

0.002 |

0.010 |

0.002 |

0.005 |

0.01 |

0.01 |

0.003 |

0.008 |

|

Mo2 |

|

- |

- |

- |

0.005 |

0.004 |

0.015 |

0.005 |

0.005 |

0.01 |

0.02 |

0.003 |

0.020 |

|

TZM |

|

0.4- |

0.06- |

0.01- |

0.002 |

0.002 |

0.01 |

0.001 |

0.005 |

0.005 |

- |

0.002 |

0.05 |

General Properties:

Density: 10.16 g/cc at 20°C

Recrystallization Temperature: 1425 to 1595°C

Stress-Relief Temperature: 1 hour at 1095 to 1260°C

Liquidus Temperature: 2620°C

Advantages of TZM Molybdenum alloy rod

Above 1100°C tensile strength is about twice that of unalloyed molybdenum

Better creep resistance

Higher recrystallization temperature

Better welding properties

Application

1. Electronic and electrical industries: TZM molybdenum rods have excellent conductivity and thermal conductivity, making them important materials in the electronic and electrical industries. It is commonly used in electronic tube cathodes, gates, high-voltage rectifying components, semiconductor thin-film integrated circuits, etc.

2. Aerospace: In the aerospace field, TZM molybdenum rods are commonly used as high-temperature furnace structural materials, radiation shielding materials, etc. due to their high temperature stability and mechanical properties.

Nuclear industry: TZM molybdenum rods are also widely used in the nuclear industry, such as radiation hoods, support frames, heat exchangers, rails, etc.

3. Glass industry: In the glass industry, TZM molybdenum rods are commonly used in the process of electrolytic preparation of glass, which can significantly improve production efficiency and product quality. Its high-temperature antioxidant performance ensures the smooth.

progress of electrolysis under high temperature conditions.

4. In the field of electricity, TZM molybdenum rods are used in molten electrolytes such as sodium sulfate to prepare oxygen and hydrogen through electrolysis, demonstrating high electrolysis efficiency and stability.

5. Chemical industry: In the chemical industry, TZM molybdenum rods can be used in reaction vessels under high temperature and high pressure conditions, and their corrosion resistance ensures efficient chemical reaction

Be used in a wide range of industries.

Steel industry

Electronic devices

Furnace components

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

The production process includes:

- Selection of high-purity molybdenum with precise titanium and zirconium alloying

- Electron beam melting for uniform composition

- Multi-stage forging and rolling to ensure consistent density and microstructure

- Precision machining to meet tight tolerances

- Inspection and packaging before shipment

|

|

|

|

|

|

|

|

Quality Control & Inspection

Quality assurance measures include:

Chemical composition analysis

Ultrasonic and dimensional inspection

Mechanical property evaluation

Microstructure verification

Final certification according to ISO 9001:2015 standards

R&D and Customization

Our R&D team develops enhanced molybdenum alloys. Customization options include:

- Tailored dimensions and tolerances

- Surface finishing: polished or ground rods

- Alloy modifications for improved high-temperature performance

- Prototype and small-batch production for testing

Packaging & Global Logistics

Each rod is carefully packaged to maintain quality:

- Vacuum or anti-rust film with foam protection

- Export-standard wooden boxes with clear labeling

- Reliable air, sea, and land logistics to 50+ global markets

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

We provide OEM and ODM services:

- Custom sizes, grades, and drawings

- Material selection guidance and technical consultation

- Prototype, small-batch, and mass production

- After-sales support for global clients

Inspection Process

Each rod undergoes:

- Incoming material verification

- Dimensional and surface inspection

- Mechanical testing for tensile strength, hardness, and creep resistance

- Final quality certification

Why Choose Us

- 30+ years of rare metal experience

- Advanced melting, forging, and machining facilities

- ISO 9001:2015 certified quality management

- Strong R&D and customization capabilities

- Fast 7-day delivery and reliable logistics

- Trusted supplier in 50+ international markets

|

|

|

|

|

|

FAQs

Q1: What is the chemical composition?

A1: High-purity molybdenum with titanium (0.5%) and zirconium (0.08%) for enhanced thermal stability.

Q2: Can custom sizes be provided?

A2: Yes, including diameters, lengths, and surface treatments.

Q3: Which industries benefit most?

A3: Aerospace, metallurgy, electronics, chemical processing, and medical equipment.

Q4: How is quality ensured?

A4: Through chemical analysis, ultrasonic testing, mechanical verification, and final certification.

Q5: Typical lead time?

A5: Standard sizes: 7 days; custom orders vary depending on specifications.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email