- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

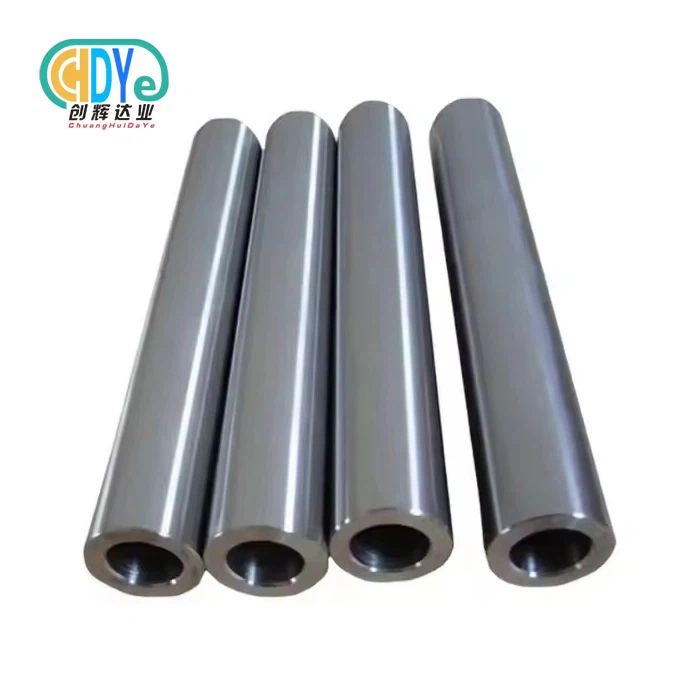

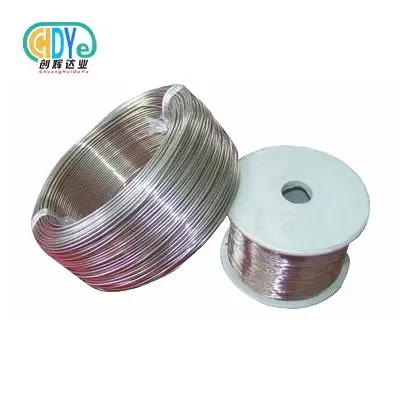

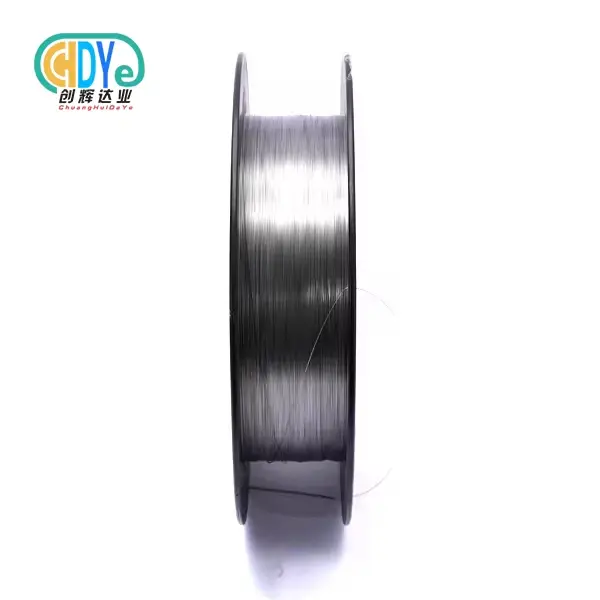

Tantalum Wire UNS R05200

Product Introduction

Tantalum is ductile, superconductive, has high-temperature strength, low thermal expansion, and high capacitance.tantalum also offers good workability and weldability. In addition, it possesses the ability to grow uniform and stable oxides with good dielectric properties. Tantalum has excellent resistance to corrosive attack by acids and liquid metals. Tantalum wire UNS R05200 is one kind of pure tantalum with 99.95% purity, And all tantalum products we supply are made in accordance with ASTM B365-98.

Diameter type: 0.15-3.0mm

Application of tantalum wire R05200

·High-temperature applications such as aircraft engines.

·Electrical devices such as capacitors.

·Surgical implants such as artificial joints and cranial plates, and surgical sutures.

·In the chemical industry e.g. for heat exchanger in boilers in which strong acids are vaporised.

·As a substitute for platinum, which is more expensive.

·In components for nuclear power plants and missiles.

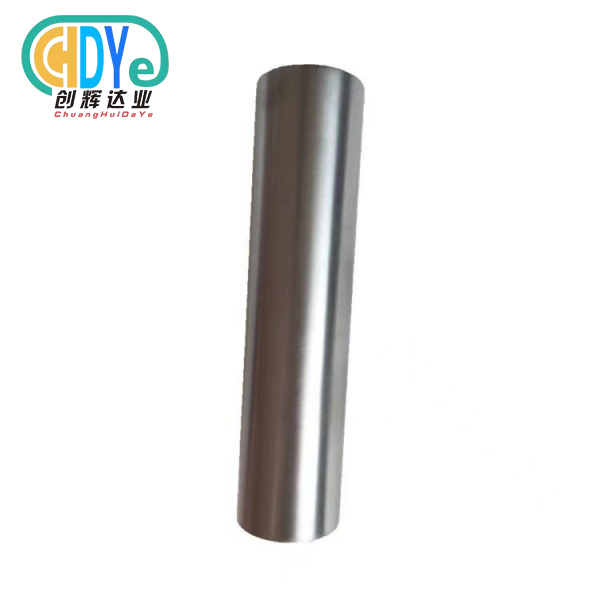

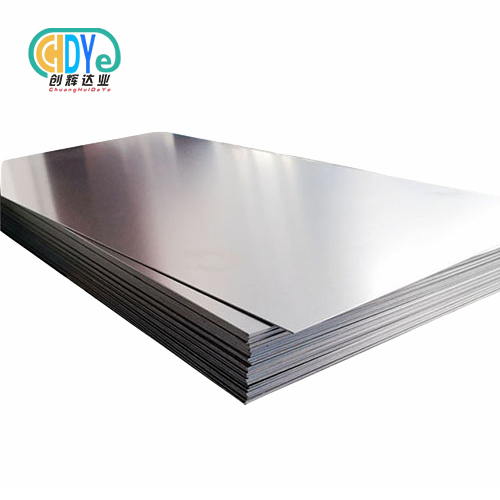

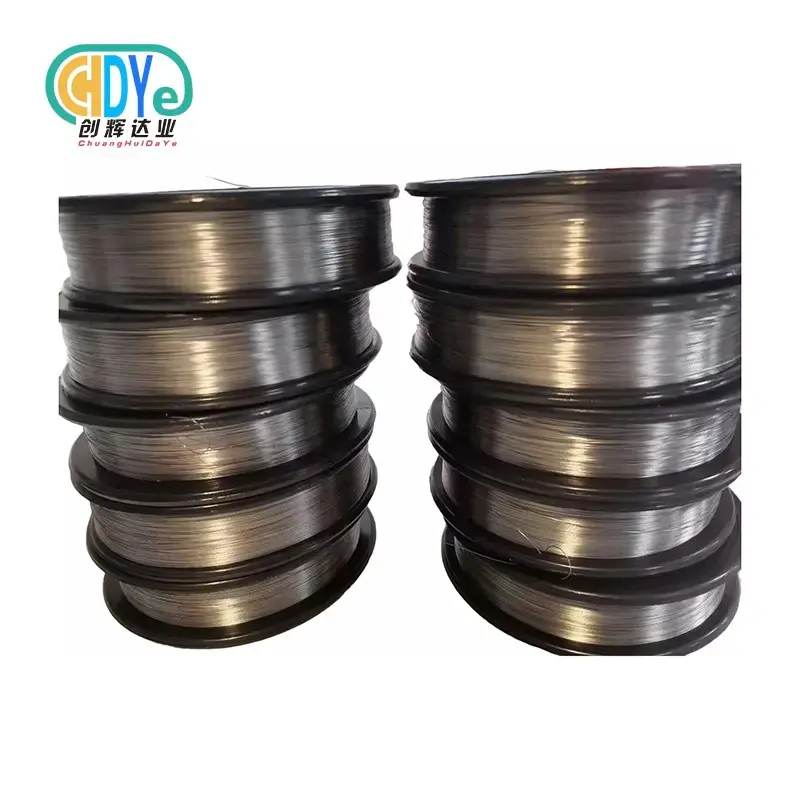

Our Products

we have common size in stock

Company profile

Shaanxi Chuanghui Daye Metal Material Co., Ltd. is located in Baoji High-tech Development Zone, Shaanxi Province, known as China's "Titanium Capital", with convenient transportation. The founder of the company has more than 30 years experience in the rare metal industry, with rich experience and strong professional ability. He serves the majority of users wholeheartedly and strives to provide users with satisfactory products.

Our main products are: titanium, tantalum, niobium, tungsten, molybdenum, zirconium and other non-ferrous and rare metal alloy products, products are widely used in metallurgy, electronics, medical and special steel fields. The company focus on quality assurance, customer first. Our company products successfully applied in the United States, Germany, South Korea, Singapore and other more than 50 countries and regions of the world.

We provide to our customers a competitive cost, on-time delivery, customer focused service, trust, reliability, honesty and continuous improvement. Please do not hesitate to contact us if you plan to work with a strong, reliable and a competitive partner.

Application Advantages

Tantalum Wire UNS R05200 offers exceptional performance in demanding environments where corrosion resistance and high-temperature stability are critical. Its superior ductility, excellent formability, and outstanding oxidation resistance make it suitable for use in electronics, aerospace, chemical processing, and medical device manufacturing. Thanks to its high melting point and biocompatibility, Tantalum Wire UNS R05200 is widely used in capacitors, thermocouples, heating elements, and surgical implants where reliability and purity are paramount.

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

The production of Tantalum Wire UNS R05200 follows a precise and controlled process to ensure the highest quality standards:

- Raw Material Selection: Premium-grade tantalum ingots are sourced and tested for purity and chemical composition.

- Melting & Forging: Electron beam or vacuum arc melting is used to achieve uniform microstructure and cleanliness.

- Rolling & Drawing: The material undergoes multi-stage hot and cold working to obtain the desired wire diameter and mechanical properties.

- Annealing Treatment: Carefully controlled annealing ensures optimum ductility and surface finish.

- Final Finishing & Inspection: Dimensional accuracy, surface integrity, and tensile strength are verified before shipment.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Shaanxi Chuanghui Daye implements a comprehensive ISO 9001:2015-certified quality system for Tantalum Wire UNS R05200 production. Every batch is tested through:

- Spectrochemical analysis to verify purity levels.

- Ultrasonic and eddy current inspection for internal flaws.

- Mechanical testing to ensure tensile strength and elongation meet ASTM B365 standards.

- Surface and dimensional checks to guarantee consistency and precision.

R&D and Customization

Our R&D department continuously advances production technologies to meet the evolving demands of high-tech industries. Customized grades, diameters, and surface finishes of Tantalum Wire UNS R05200 can be produced according to client drawings or special applications. We provide technical consultation to support prototype development, ensuring the best material match for each engineering requirement.

Packaging & Global Logistics

Each wire coil is vacuum-packed or sealed with anti-rust film, cushioned with foam, and enclosed in an export-grade wooden case. Clear labeling with batch number, grade, and specifications ensures full traceability. Our global logistics network ensures safe and prompt delivery of Tantalum Wire UNS R05200 to clients in over 50 countries via air, sea, or land transportation.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Shaanxi Chuanghui Daye offers full OEM and ODM capabilities, enabling clients to specify wire dimensions, purity levels, and surface conditions. We support:

- Prototype and small-lot production

- Custom spooling and packaging options

- Application-specific design assistance

- Consistent batch production with quick turnaround

Inspection Process

Before delivery, each production lot undergoes a strict multi-stage inspection process including:

- Raw material certification verification

- Dimensional and surface evaluation

- Mechanical testing under controlled conditions

- Final visual and packing inspection

All inspection data is documented and available for customer review.

Why Choose Us

- 30+ years of expertise in rare metal manufacturing

- ISO 9001:2015 quality certification and traceable production

- Fast 7-day delivery for standard products

- Competitive pricing and global export experience

- Professional R&D team for technical customization and long-term cooperation

|

|

|

|

|

|

FAQs

Q1: What is the purity level of your tantalum wire?

A1: Standard purity is 99.95%, with ultra-high purity 99.99% available upon request.

Q2: What size range do you offer?

A2: Diameters range from 0.1 mm to 5.0 mm, with customization available.

Q3: Can you provide samples or trial orders?

A3: Yes, small-batch and prototype quantities are available for testing or R&D.

Q4: What is your typical delivery time?

A4: Standard products are shipped within 7 days; customized orders depend on specifications.

Q5: Which industries commonly use tantalum wire products?

A5: They are widely applied in electronics, aerospace, chemical, and medical fields due to their stability and corrosion resistance.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email