- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

niobium sputtering target disc

Density:16.6 g/ cm 3

Purity : 99.95%min

size: customized

Condition: Vacuum Annealed

Surface: Alkaline wash surface / machined

Processing technic: CNC Milling Machinery

Product Introduction

When you need reliable materials for advanced thin film applications, our niobium sputtering target disc delivers exceptional performance. These high-purity discs offer precise dimensions and superior conductivity for your most demanding projects. Our niobium targets maintain excellent plasma stability during sputtering processes. You'll achieve consistent results with every deposition cycle. Whether you're working on semiconductor manufacturing or superconducting applications, these targets meet strict industry standards. Each disc undergoes rigorous quality testing to ensure optimal performance in your specific application requirements.

Key Features and Benefits

Your projects benefit from several key advantages when you choose our niobium targets:

- Superior Purity: 99.95% purity enables superconducting applications

- Excellent Conductivity: Low oxygen content (≤100 ppm) enhances electrical performance

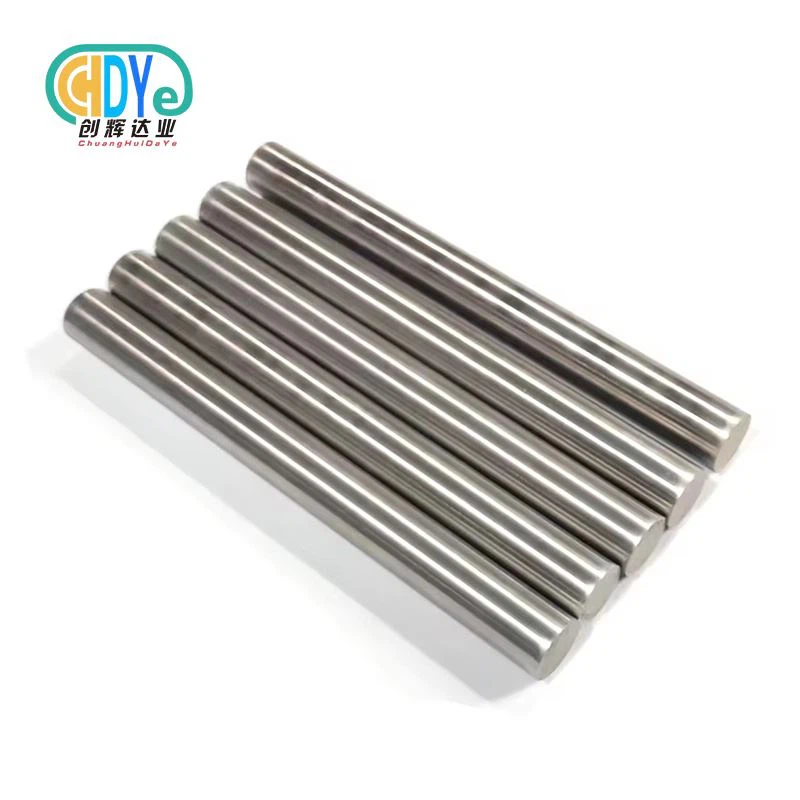

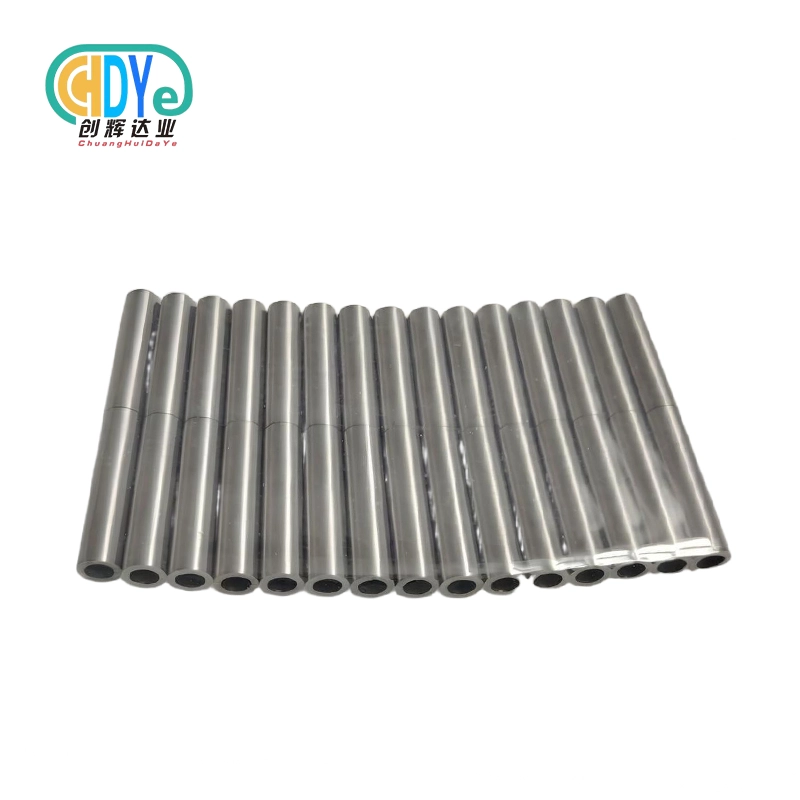

- Precise Dimensions: Thickness tolerance of ±0.015 mm ensures consistent film quality

- High Density: ≥99.7% theoretical density improves sputtering efficiency

- Corrosion Resistance: Withstands acids, alkalis, and chemical substances

- Temperature Stability: High melting point (2477°C) maintains performance under extreme conditions

Technical Specifications

| Parameter | Specification |

|---|---|

| Purity | 99.95% min |

| Density | ≥99.7% theoretical (8.5 g/cm³) |

| Oxygen Content | ≤100 ppm |

| Diameter Range | 75-300 mm |

| Thickness Tolerance | ±0.015 mm |

| Flatness | ≤0.03 mm |

| Heat Load Resistance | 260 W/cm² |

| Deposition Rate | 6-10 nm/s at 500 W |

Available Grades and Materials

We offer industry-standard grades that meet your specific requirements:

| Grade | Standard | Application |

|---|---|---|

| R04200 | ASTM B 392 | General sputtering applications |

| R04210 | ASTM B 392 | High-purity applications |

Chemical composition

|

Grade |

Main component |

Impurity content(≤) |

||||||||||

|

Ta |

Fe |

Si |

Ni |

W |

Mo |

Ti |

Nb |

O |

C |

H |

N |

|

|

Ta1 |

Residual |

0.005 |

0.005 |

0.002 |

0.01 |

0.01 |

0.002 |

0.03 |

0.015 |

0.01 |

0.0015 |

0.01 |

|

Ta2 |

Residual |

0.03 |

0.02 |

0.005 |

0.04 |

0.03 |

0.005 |

0.1 |

0.02 |

0.01 |

0.0015 |

0.01 |

Manufacturing Process

Tantalum powder produced by the sodium thermal reduction method has a bulk density of 1.8-2.6 g/cm³ and a particle size of 2-3 microns. The tantalum powder is cold isostatically pressed in a latex jacket at a pressure greater than 200 MPa and a holding time greater than 20 minutes to produce a tantalum ingot.

The tantalum ingot is sintered at a vacuum greater than 10-2 MPa, a temperature greater than 2400°C, and a holding time greater than 1.5 hours. The resulting tantalum ingot has a density of 15.4 g/cm³ and a purity of 99.99%.

The sintered tantalum ingot is rolled at a total processing rate of 30%-60%. It is then heat treated at a temperature between 25% and 45% of the tantalum ingot's melting point to produce the tantalum target.

This preparation method is to produce tantalum target processing blanks by powder metallurgy method, which has the advantages of fine and uniform internal structure and a texture-free internal structure; and then through pressure processing technology and heat treatment technology, a fine and uniform internal structure is obtained, which meets the requirements of tantalum target materials used in high-end sputtering machines.

|

|

|

|

|

|

|

|

Applications and Industries

Your niobium sputtering target disc serves multiple industries effectively:

Semiconductor Manufacturing: Essential for creating conductive layers in microchips and electronic components. Physical vapor deposition processes rely on these targets for precise film thickness control.

Display Technology: LCD manufacturing uses niobium thin films for transparent electrode layers. These applications demand exceptional uniformity and conductivity.

Energy Sector: Solar panel production benefits from niobium coatings that improve conversion efficiency and long-term stability.

Medical Devices: Biocompatible properties make niobium ideal for dental implants and surgical instruments.

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

Standard dimensions accommodate most sputtering systems:

- Minimum diameter: 75 mm

- Maximum diameter: 300 mm

- Minimum thickness: above1 mm

- Custom sizes available upon request

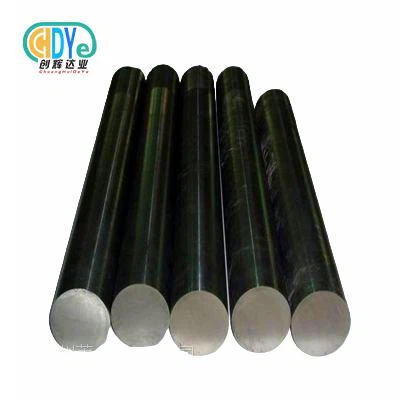

Product Features in Detail

Each disc features carefully controlled microstructure for optimal sputtering performance. Surface finishes include both cold-rolled and machined options to match your equipment requirements. Uniform grain size distribution ensures consistent deposition rates across the target surface. Low gas content prevents contamination during the sputtering process.

Quality Assurance and Testing

Every target undergoes comprehensive testing before shipment. Chemical composition analysis verifies purity levels. Dimensional inspection confirms tolerance requirements. Surface quality checks ensure proper finish specifications. Density measurements validate material integrity.

|

|

|

OEM & Customization Services

We understand that your applications may require specific configurations. Our engineering team works closely with you to develop custom solutions. Special alloy compositions, unique dimensions, and specific surface treatments are available. Contact us to discuss your particular requirements.

Packaging and Shipping

Protective packaging prevents damage during transportation. Vacuum-sealed containers maintain surface cleanliness. Foam padding cushions against impact. International shipping options ensure timely delivery worldwide. All packages include detailed specifications and handling instructions.

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd. brings over 30 years of rare metal expertise to every product. Located in China's "Titanium Capital," we combine advanced manufacturing with competitive pricing. Our products serve customers across 50+ countries successfully. You receive reliable quality, on-time delivery, and responsive customer service with every order.

When you choose our niobium sputtering target disc, you partner with industry leaders committed to excellence. We focus on building long-term relationships through consistent quality and dependable service.

1.You can get the perfect material according to your requirement at the least possible price.

2.We offer FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

3. we provide raw material test certificate to the final dimensional statement.(Reports will show on requirement)

4. You can get stock alternatives, usually stock size we can arrange 1-3 days quick delivery to save your time.

5.We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

|

|

|

|

|

|

FAQs

Q: What's the typical lead time for standard sizes?

A: Standard sizes typically ship within 10-12days after order confirmation.

Q: Can you provide material certificates?

A: Yes, we include complete material certificates with chemical composition and physical properties.

Q: Do you offer technical support for sputtering parameters?

A: Our technical team provides guidance on optimal sputtering conditions for your specific application.

Contact Us

Ready to enhance your thin film processes? Our team stands ready to help you select the perfect niobium sputtering target disc for your applications.

Email us at info@chdymetal.com for technical specifications, pricing, or custom requirements. We respond to all inquiries within 24 hours and look forward to supporting your project success.

Learn about our latest products and discounts through SMS or email