- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

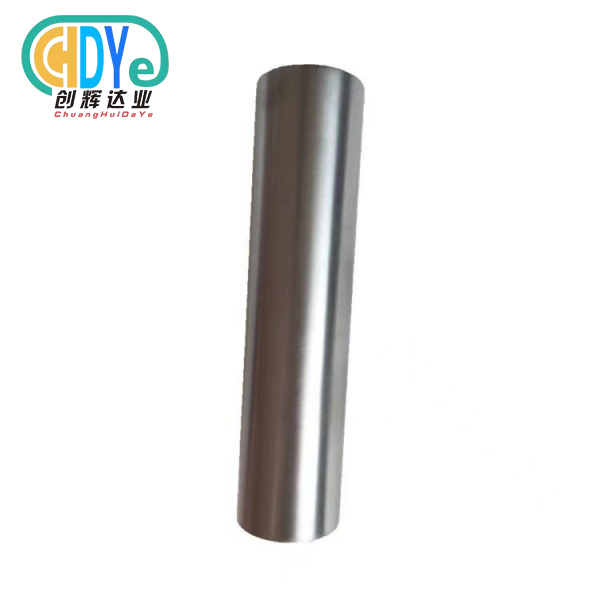

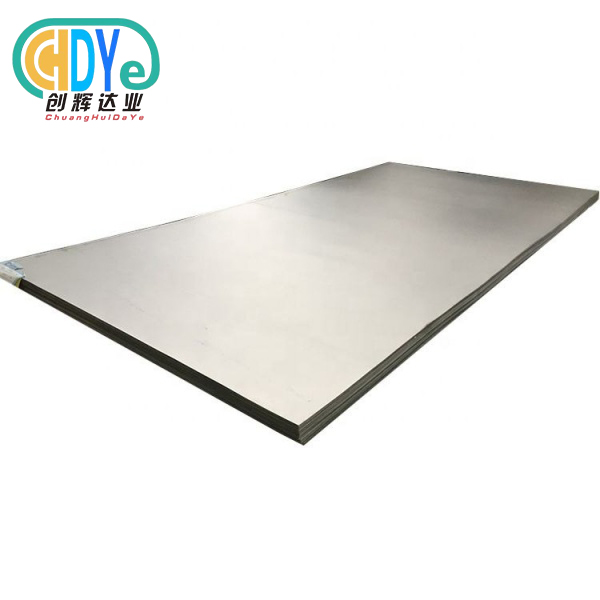

High Purity Molybdenum Crucible

Material: Mo, TZM, MoLa Alloy

Production Method: Sintering, forging,sintering,and machining.

Product Introduction

The High Purity Molybdenum Crucible offered by Shaanxi Chuanghui Daye Metal Material Co., Ltd. is a precision-engineered product designed for use in extreme high-temperature, high-vacuum, and chemically demanding environments. Manufactured from molybdenum with a minimum purity of 99.95%, it provides exceptional thermal conductivity, mechanical strength, and corrosion resistance. This crucible ensures excellent dimensional stability even under prolonged exposure to temperatures above 2000°C, making it ideal for use in melting, sintering, and crystal growth processes that require contamination-free conditions.

This product is developed under strict production control and international quality standards, ensuring reliable performance for global industrial and research applications.

High purity Molybdenum Crucible has a high melting point, high-temperature strength, low outgassing, and good machinability. Molybdenum crucibles are mainly used in the metallurgical industry, rare earth industry, monocrystalline silicon and crystal growth. Chdymetal provide Molybdenum crucibles are made of 99.95% high purity Mo and are ideal for sapphire crystal growth and rare-earth melting.

Size: 10-400mm OD x 10-600mm H, customized

Material: Mo, TZM, MoLa Alloy

Production Method: Sintering, forging, sintering, and machining.

Purity: 99.95%,

|

Density |

state |

size |

|

>10.1g/cm3 |

forging |

Diameter10-130mm; height 10-200mm |

|

>9.8g/cm3 |

sintering |

Diamete10-400mm; height 50-600mm |

Molybdenum crucible type

high quality best price induction melting molybdenum crucible

* Pressed and Sintered Crucibles

The powder is pressed and sintered to the final shape. They are one of the types of the most popular crucibles.

* Spin-formed Crucibles

Large molybdenum plate blanks are hot spun-formed to the specified product geometry.

* Milled Crucibles

Material blanks are machined to the final product. This type of molybdenum crucible is also very popular.

* Welded Crucibles

Large crucibles with thinner wall thickness, and we recommend welded molybdenum crucibles.

Application

The High Purity Molybdenum Crucible is widely used in industries where precision and purity are essential for maintaining process integrity:

Metallurgical industry

Sapphire single crystal growth furnace

Quartz glass smelting furnaces

Rear earth smelting furnaces

Solar energy

Artificial Crystal

Mechanical processing industries

Be used in a wide range of industries.

Steel industry

Electronic devices

Furnace components

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

Shaanxi Chuanghui Daye ensures every High Purity Molybdenum Crucible meets the highest international standards through the following stages:

- Raw Material Selection: Only verified high-purity molybdenum powders are used.

- Cold Isostatic Pressing: Ensures even density and structural integrity.

- Vacuum Sintering: Reduces impurities and enhances mechanical performance.

- Hot Forging & Rolling: Improves grain uniformity and mechanical strength.

- CNC Machining: Achieves precise dimensions and superior surface quality.

- Final Finishing: Grinding and polishing based on customer requirements.

Each step is supervised by skilled technicians to meet international ASTM and ISO standards.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Quality is strictly managed throughout the entire manufacturing process:

- Chemical Analysis: Confirms purity and alloy composition.

- Mechanical Testing: Evaluates hardness, ductility, and tensile strength.

- Dimensional Inspection: Uses precision instruments to verify tolerance accuracy.

- Non-Destructive Testing: Ultrasonic and visual checks ensure defect-free surfaces.

- Final Review: Each crucible passes multiple inspections before delivery.

The company’s ISO 9001:2015 certification guarantees consistency, reliability, and full traceability of every product.

R&D and Customization

With a dedicated research and development team, Shaanxi Chuanghui Daye continues to improve product performance and customization capabilities. Our engineers focus on:

- Enhancing heat resistance and oxidation protection.

- Developing new crucible shapes and thin-wall designs.

- Providing custom diameters, wall thicknesses, and tolerances.

- Optimizing microstructure for extended service life in demanding environments.

Through continuous innovation, we meet the needs of customers in metallurgical, semiconductor, and coating industries worldwide.

Packaging & Global Logistics

To ensure the safe delivery of every crucible, each product is carefully handled and securely packaged:

- Protective Wrapping: Vacuum-sealed or anti-rust film to prevent oxidation.

- Shock-Absorbing Layers: Foam or sponge lining to reduce vibration damage.

- Export Wooden Boxes: Certified for international air and sea freight.

- Clear Marking: Includes grade, dimensions, and batch number for traceability.

Global logistics support covers more than 50 export destinations, including the United States, Germany, South Korea, and Singapore.

|

|

|

|

|

|

|

|

|

|

|

|

OEM & Customization Service

Shaanxi Chuanghui Daye offers comprehensive OEM and ODM support, helping customers meet specific industrial requirements. Services include:

- Custom designs according to drawings or technical parameters.

- Prototype and small-batch production for R&D use.

- Material and process consulting for new applications.

- Flexible lead times and competitive global shipping solutions.

Our technical team ensures every project achieves the perfect balance between quality, cost, and performance.

Inspection Process

Inspection is an essential stage to maintain the superior quality of each High Purity Molybdenum Crucible:

- Raw Material Verification: Checking the purity and grain size of molybdenum powder.

- In-Process Monitoring: Supervising temperature, pressure, and density control.

- Ultrasonic Scanning: Detecting any internal inclusions or voids.

- Dimensional Measurement: Ensuring all parts meet customer specifications.

- Final Documentation: Including test reports and certificates of analysis.

Each crucible delivered to customers is fully traceable from raw material to final inspection.

Why Choose Us

- 30+ Years of Expertise: Proven experience in rare metal manufacturing.

- Advanced Production Facilities: Equipped with vacuum furnaces, forging machines, and CNC tools.

- Strict Quality Assurance: Certified under ISO 9001:2015.

- Global Export Reach: Supplying to more than 50 countries.

- Professional Service: Customized technical consultation and after-sales support.

- Fast Turnaround: Quick delivery time within 7 days for standard sizes.

Shaanxi Chuanghui Daye remains a trusted supplier known for its quality, reliability, and customer-focused approach.

|

|

|

|

|

|

FAQs

Q1: What is the purity of the molybdenum used?

A1: The molybdenum purity exceeds 99.95%, ensuring high performance and minimal contamination.

Q2: Can you produce customized crucible sizes or shapes?

A2: Yes, we provide full customization according to drawings or special requirements.

Q3: What are the typical applications of this crucible?

A3: It is commonly used in metallurgy, semiconductors, coating, and high-temperature melting processes.

Q4: How do you ensure quality consistency?

A4: Every product is inspected through chemical analysis, mechanical tests, and non-destructive evaluation before shipment.

Q5: What is the delivery time?

A5: Standard orders can be fulfilled within 7 working days, with express options for urgent needs.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email

_1760924769851.jpg)