- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

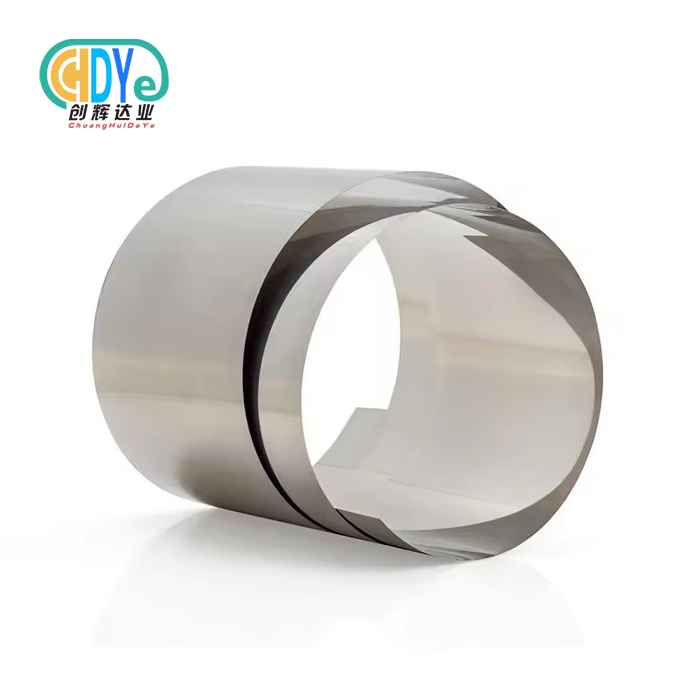

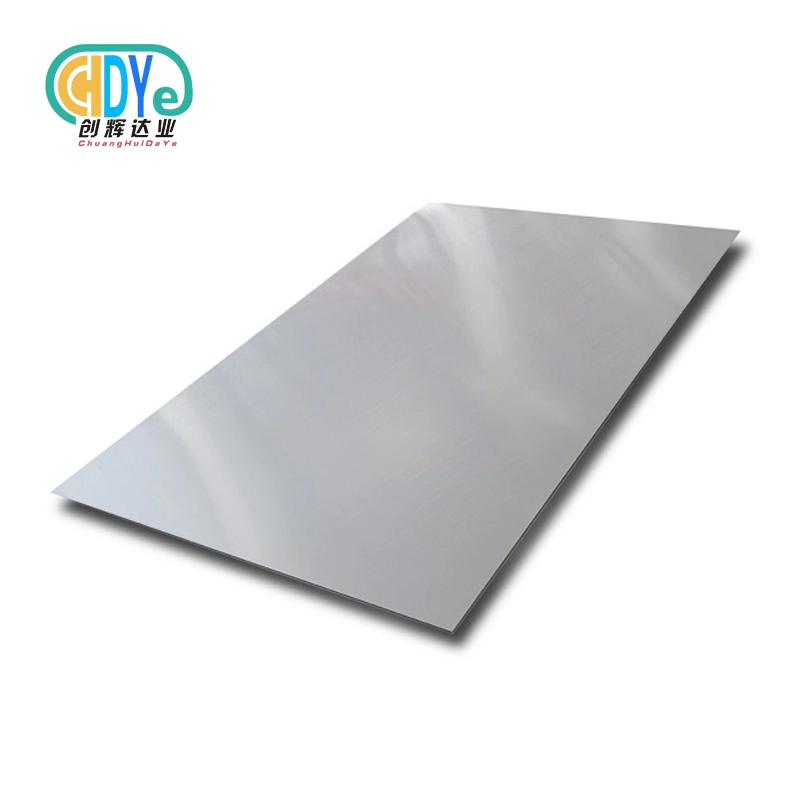

titanium metal plate

2. Thickness 0.5-50mm

3. Width 500-2000mm

4. Length 1000-6000mm

5. Density 4.43-4.51 g/cm³

6. Excellent corrosion resistance

7. High strength-to-weight ratio

Looking for high-performance titanium metal plate solutions? You've come to the right place. Our premium titanium metal plate products deliver exceptional strength, corrosion resistance, and reliability for your most demanding applications. With over 30 years of experience in rare metal manufacturing, we provide superior quality plates that meet international standards and exceed customer expectations worldwide.

Product Introduction

Our titanium plates represent the perfect balance of strength, lightweight properties, and exceptional durability. Made from pure titanium and high-grade alloys, these plates offer outstanding performance across various industrial applications. Whether you need standard dimensions or custom specifications, our manufacturing capabilities ensure you receive exactly what your project requires.

Key Features and Benefits

Superior Corrosion Resistance: Withstands harsh chemical environments and extreme conditions

High Strength-to-Weight Ratio: Delivers maximum performance with minimal weight

Excellent Biocompatibility: Perfect for medical and pharmaceutical applications

Temperature Resistance: Maintains properties in extreme temperature ranges

Long Service Life: Reduces replacement costs and maintenance requirements

Versatile Processing: Easy to machine, weld, and fabricate

Technical Specifications

Our titanium plates meet stringent technical requirements:

- Thickness Range: 0.5mm to 50mm

- Width Options: 500mm to 2000mm

- Length Availability: 1000mm to 6000mm

- Density: 4.43-4.51 g/cm³

- Tensile Strength: Up to 550 MPa

- Yield Strength: Up to 485 MPa

Available Grades and Materials

We offer comprehensive grade options to match your specific needs:

Grade 1: Maximum ductility and excellent forming characteristics

Grade 2: Most commonly used commercial pure titanium

Grade 3: Medium strength with good formability

Grade 4: Higher strength while maintaining good ductility

Grade 5 (Ti-6Al-4V): High strength titanium alloy for demanding applications

|

|

N |

C |

H |

Fe |

O |

Al |

V |

Pa |

Mo |

Ni |

Ti |

|

Gr 1 |

0.03 |

0.08 |

0.015 |

0.20 |

0.18 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 2 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 3 |

0.05 |

0.08 |

0.015 |

0.30 |

0.35 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 4 |

0.05 |

0.08 |

0.015 |

0.50 |

0.40 |

/ |

/ |

/ |

/ |

/ |

|

|

Gr 5 |

0.05 |

0.08 |

0.015 |

0.40 |

0.20 |

5.5~6.75 |

3.5~4.5 |

/ |

/ |

/ |

bal |

|

Gr 7 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

0.12~0.25 |

/ |

/ |

bal |

|

Gr 9 |

0.03 |

0.08 |

0.015 |

0.25 |

0.15 |

2.5~3.5 |

2.0~3.0 |

/ |

/ |

/ |

bal |

|

Gr12 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

/ |

0.2~0.4 |

0.6~0.9 |

|

Manufacturing Process

Our advanced manufacturing process ensures consistent quality:

- Raw Material Selection: Premium titanium ingots from certified suppliers

- Hot Rolling: Precise temperature control for optimal grain structure

- Cold Rolling: Achieving exact thickness specifications

- Heat Treatment: Stress relief and property optimization

- Surface Finishing: Various surface treatments available

- Quality Inspection: Comprehensive testing before shipment

Applications and Industries

Titanium plates serve diverse industries:

Aerospace: Aircraft components, engine parts, structural elements

Medical: Surgical implants, prosthetics, medical devices

Chemical Processing: Reactor vessels, heat exchangers, piping systems

Marine: Offshore platforms, submarine components, propeller shafts

Automotive: Performance parts, exhaust systems, racing components

Electronics: Heat sinks, electronic housings, semiconductor equipment

Be used in a wide range of industries.

Marine engineering

Medical implants

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

We maintain strict dimensional tolerances:

- Thickness Tolerance: ±0.05mm for thin sheets, ±0.1mm for thick plates

- Width Tolerance: ±2mm

- Length Tolerance: ±5mm

- Flatness: Better than 2mm per meter

- Surface Finish: Ra ≤ 1.6μm standard

Product Features in Detail

Our manufacturing excellence shows in every detail. The uniform grain structure provides consistent mechanical properties throughout each plate. Surface quality meets international standards with minimal porosity and excellent finish. Chemical composition control ensures reliable performance in your specific application environment.

Quality Assurance and Testing

Every plate undergoes rigorous testing:

- Chemical Analysis: Verifying composition compliance

- Mechanical Testing: Tensile, yield, and elongation properties

- Ultrasonic Testing: Internal defect detection

- Surface Inspection: Visual and dimensional verification

- Certification: Complete material certificates provided

|

|

|

OEM & Customization Services

We specialize in custom solutions. Our engineering team works closely with you to develop plates meeting your exact specifications. From unique dimensions to special surface treatments, we adapt our manufacturing process to deliver precisely what you need.

Packaging and Shipping

Professional packaging protects your investment:

- Individual Protection: Each plate wrapped in protective film

- Wooden Crates: Secure packaging for international shipping

- Documentation: Complete shipping and quality documents

- Global Delivery: Worldwide shipping to over 50 countries

|

|

|

|

|

|

|

|

|

Why Choose Us

Located in China's "Titanium Capital," we combine three decades of industry expertise with modern manufacturing capabilities. Our founder's extensive experience in rare metals ensures you receive products meeting the highest standards. We've successfully served customers across the United States, Germany, South Korea, Singapore, and many other countries.

Our commitment goes beyond manufacturing. We provide competitive pricing, on-time delivery, and customer-focused service built on trust, reliability, and honesty.

|

|

|

|

|

|

FAQs

Q: What's the minimum order quantity?

A: We accommodate both small prototype orders and large production runs.

Q: Can you provide custom sizes?

A: Yes, we specialize in custom dimensions and specifications.

Q: What certifications do you provide?

A: Complete material certificates including chemical and mechanical test reports.

Q: How long is the delivery time?

A: Typically 1-2 weeks depending on specifications and quantity.

Contact Us

Ready to discuss your titanium metal plate requirements? Our technical team stands ready to help you select the perfect solution for your application. Contact us today at info@chdymetal.com for detailed quotations, technical specifications, or any questions about our products and services.

Learn about our latest products and discounts through SMS or email