- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

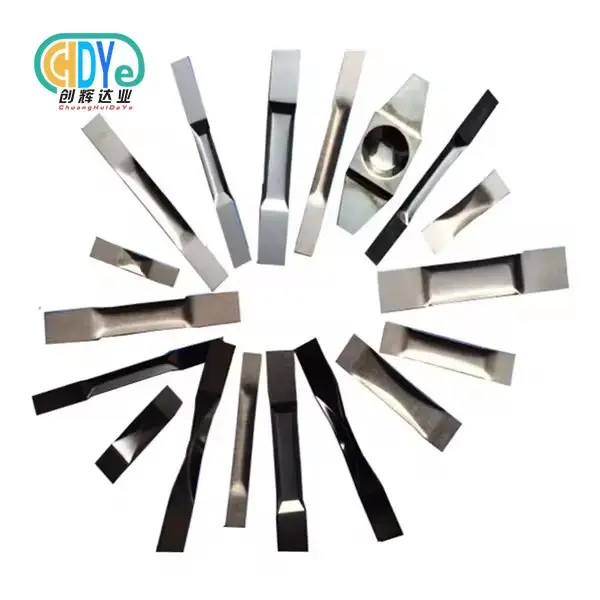

Molybdenum Boat

Product Introduction

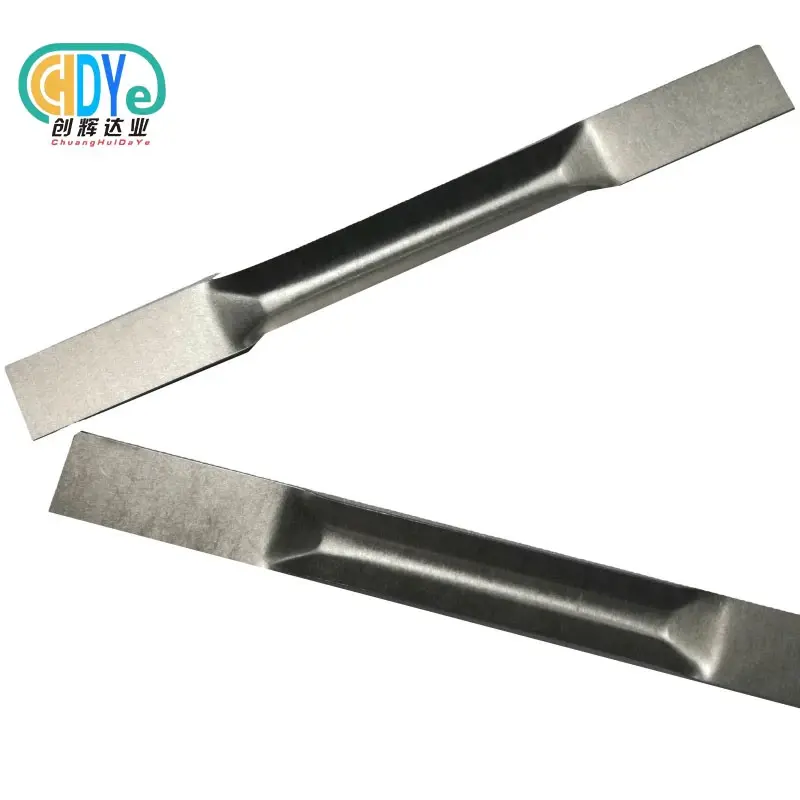

The Molybdenum Boat is an essential component used in high-temperature and vacuum applications due to its excellent thermal conductivity, high melting point, and outstanding resistance to corrosion and deformation. Manufactured by Shaanxi Chuanghui Daye Metal Material Co., Ltd., the product is designed for precise metal evaporation, sintering, and heat treatment processes in semiconductor, electronic, and metallurgical industries. Each Molybdenum Boat is made from high-purity molybdenum material, ensuring stable performance and long service life even under extreme conditions. Our advanced production technology guarantees tight dimensional tolerance, smooth surface finish, and reliable structural integrity suitable for vacuum coating systems and thermal evaporation equipment.

|

Name |

Molybdenum Boat |

|||

|

Material |

Pure Molybdenum: Mo≥99.95% TZM molybdenum alloy: C:0.014%, Ti:0.65%, Zr: 0.071% Molybdenum Lanthanum alloy: Mo≥99.27%, La=0.62% |

|||

|

Specifications |

L (20-1000) mm * W (20-500) mm * Wall Thickness (0.2-30)mm |

|||

|

Max. temp |

1800 ℃ |

|||

|

working temp |

0-1700 ℃ |

|||

|

Purity |

≥99.95% |

|||

|

Density |

≥10.2g/cm3 |

|||

|

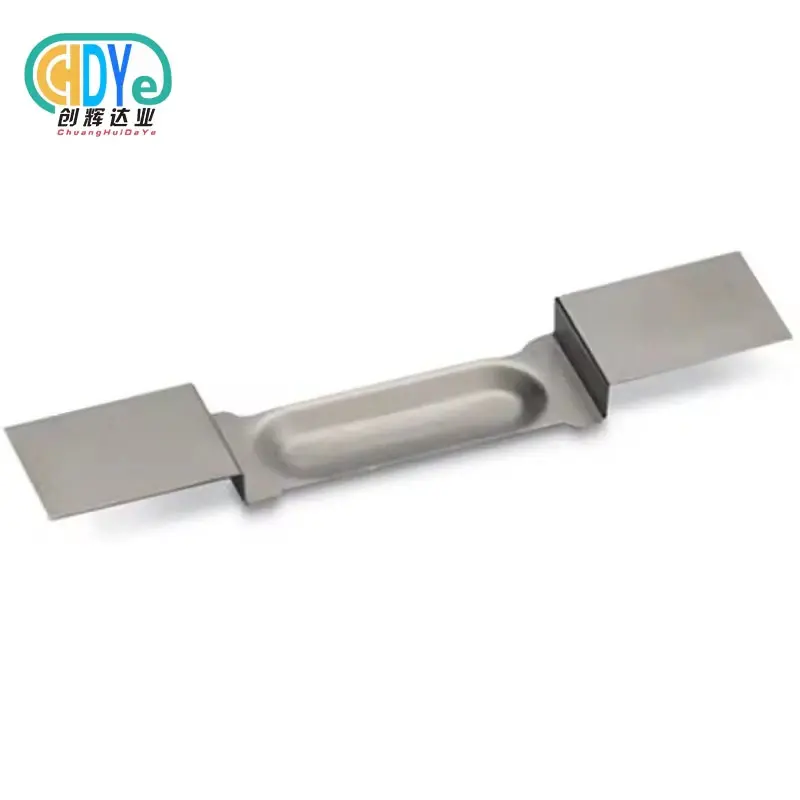

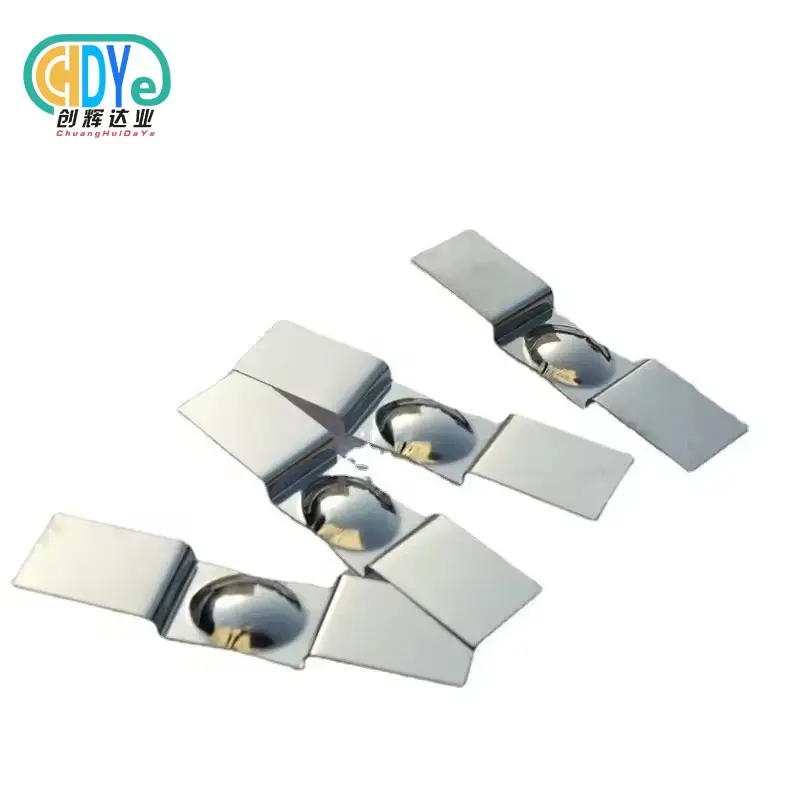

Shape |

square box, round barrel or other customized |

|||

|

Joining method |

riveted, folded or welded |

|||

|

processing technic |

hot rolled, alkaline wash, surface defect polishing treatment, cold rolling annealing |

|||

|

Feature |

no internal crack, precise size, surface smooth and clean. |

|||

|

Surface |

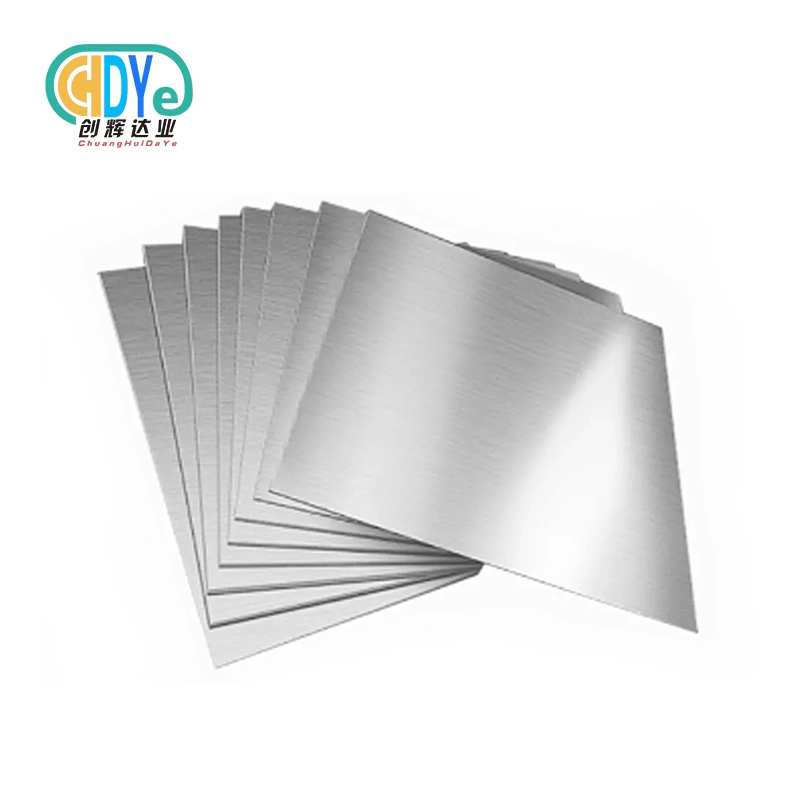

cold rolled, hot rolled, alkali washing, sand blast and polished surface. |

|||

|

Application |

1) Widely used in sapphire crystal growth furnace and vacuum furnace; 2) Used in production of tropical, fittings, plasma deposition sputtering target material, high temperature resistant boat and other products; 3) Used for metal and non-metallic materials sintering; 4) Used in vacuum furnace and atmosphere furnace. |

|||

|

Specification of molybdenum boat |

||||

|

Dimensions (Customized) |

Length |

Width |

Hight |

Thickness |

|

20mm-1000mm |

20mm-500mm |

Customized |

0.2mm-30mm |

|

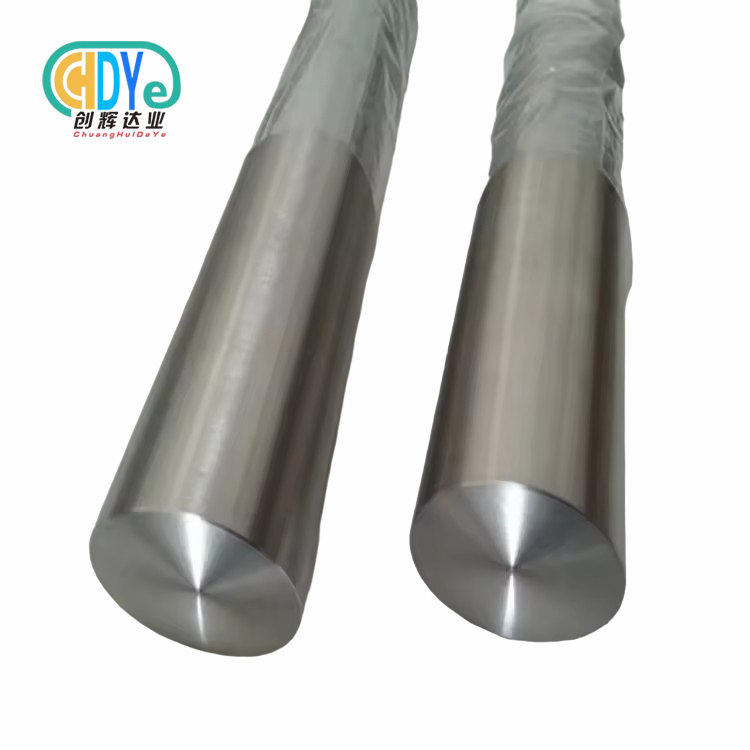

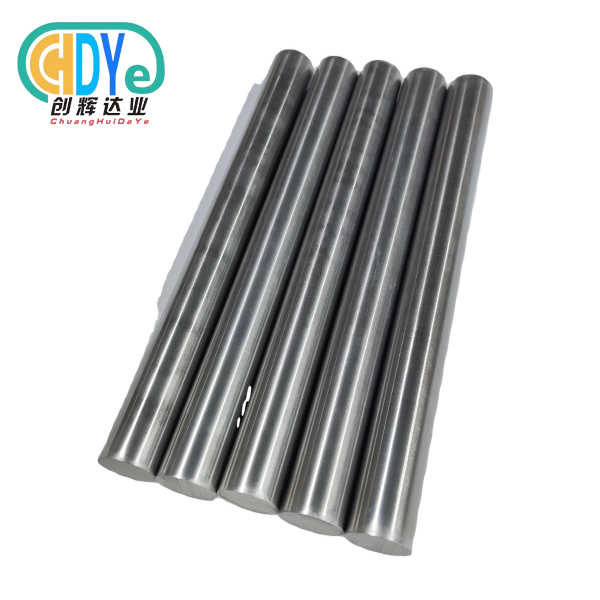

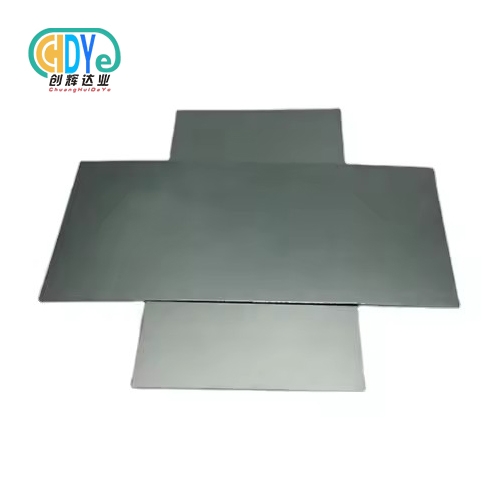

OUR PRODUCTS

Application Advantages

The Molybdenum Boat is widely applied in various industrial and scientific processes requiring high-temperature stability and minimal contamination. Typical applications include:

- Vacuum evaporation and coating: Used in optical and semiconductor thin film deposition.

- Metal and ceramic sintering: Supports high-temperature processes with exceptional oxidation resistance.

- Laboratory experiments: Provides uniform heating and melting of materials in research environments.

- Electronics and aerospace industries: Functions as a high-efficiency thermal container in controlled environments.

Be used in a wide range of industries.

Steel industry

Electronic devices

Furnace components

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

Our production process is based on precise control and advanced equipment:

- Raw material selection: Only high-purity molybdenum powder is used to ensure superior performance.

- Powder pressing and sintering: High-temperature sintering ensures a dense and uniform structure.

- Rolling and machining: The molybdenum sheet is rolled to exact dimensions and cut into required sizes.

- Forming: Boats are formed using CNC bending and shaping technology for precise geometry.

- Surface finishing: Mechanical polishing removes impurities and improves smoothness.

- Final inspection: Each piece undergoes strict dimensional and purity testing before shipment.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Quality assurance is the foundation of our production philosophy. Every batch of products is tested following ISO 9001:2015 quality management standards.

- Raw material inspection: Verification of purity and physical properties.

- Dimensional accuracy check: Micrometer and optical measurement for precision tolerance.

- Mechanical performance testing: Tensile and hardness testing to ensure strength.

- High-temperature resistance evaluation: Simulated performance under operational conditions.

R&D and Customization

Shaanxi Chuanghui Daye Metal Material Co., Ltd. maintains a strong R&D capability focused on developing high-performance refractory metal products. We provide customized designs for unique industrial requirements, including:

- Special shapes, sizes, and thicknesses for different vacuum systems.

- Surface treatment for enhanced oxidation resistance.

- Prototype development for experimental and research applications.

Our dedicated R&D team continuously refines production techniques to enhance performance and extend the service life of our molybdenum products.

Packaging & Global Logistics

We guarantee safe, efficient, and professional packaging and transportation for all molybdenum products.

- Packaging: Vacuum-sealed with moisture-proof protection, cushioned by foam and packed in export-grade wooden boxes.

- Marking: Each package is clearly labeled with grade, dimensions, and batch numbers for easy traceability.

- Logistics: Reliable delivery via air, sea, or express to over 50 countries, ensuring timely arrival in perfect condition.

Every shipment from Shaanxi Chuanghui Daye reflects our commitment to quality and safety during global transportation.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

We provide full OEM and ODM support for international customers.

- Custom production: Tailored according to drawings and technical requirements.

- Material guidance: Expert consultation on selecting suitable molybdenum grades.

- Prototype manufacturing: Small-batch trial production for performance validation.

- After-sales support: Technical assistance throughout the product’s service life.

Shaanxi Chuanghui Daye ensures flexibility, precision, and professionalism in every customized solution.

Inspection Process

To ensure that every product meets customer expectations, we implement a strict multi-stage inspection system:

- Material verification: Confirming purity and source authenticity.

- Dimensional inspection: Measuring shape, size, and thickness accuracy.

- Surface and defect check: Visual and microscopic analysis for surface smoothness.

- Performance validation: Thermal stability and deformation testing.

- Final approval: Independent QA department validation before shipment.

This detailed inspection process guarantees reliability and long-term performance in demanding applications.

Why Choose Us

- Over 30 years of rare metal expertise

- ISO 9001:2015 certified quality system

- Advanced manufacturing and R&D capability

- Global logistics and responsive service

- Competitive pricing and fast delivery

Choosing Shaanxi Chuanghui Daye means partnering with a trusted supplier committed to excellence, precision, and innovation in refractory metal solutions.

|

|

|

|

|

|

FAQs

Q1: What is the purity level of your molybdenum boats?

A1: Our molybdenum boats are made from 99.95% or higher purity molybdenum for superior thermal and mechanical performance.

Q2: Can you produce customized shapes and dimensions?

A2: Yes, we provide OEM customization according to technical drawings and customer specifications.

Q3: How do you ensure quality consistency?

A3: Each production stage follows ISO 9001 standards, with complete traceability and detailed inspection reports.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email