- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

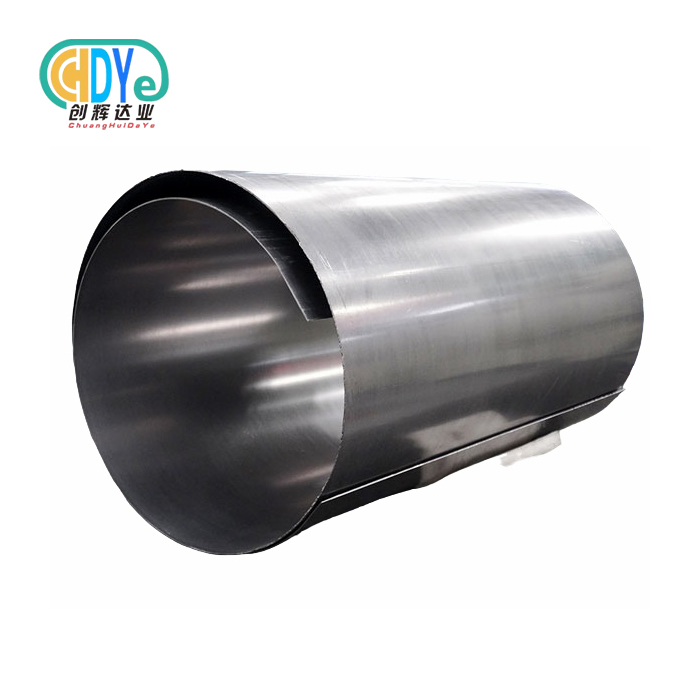

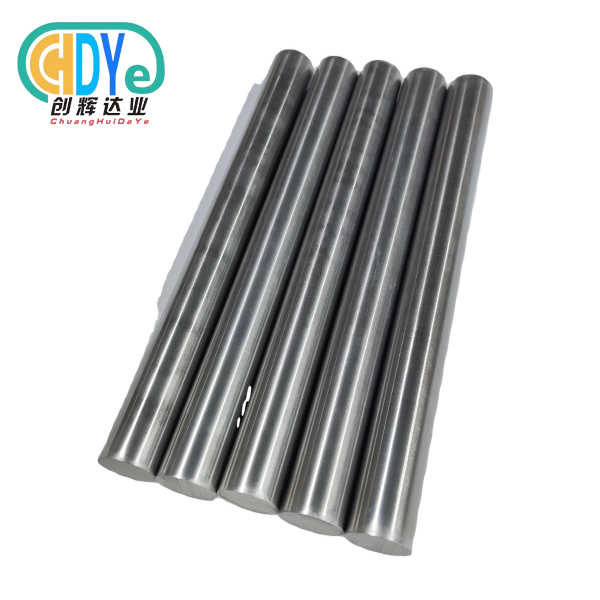

Grade 2 Titanium Round Bar

2.Standard: ASTMB348,ASTM F67,ASTM F136

3.Type: Round, Square, Hexagon

Products Description

Chdymetal is a global metal supplier of Grade 2 titanium round bar, we can provide various grade and type, As its unique combination of high strength, light weight, corrosion resistance, bio-compatibility, and higher temperature performance, Titanium round bar is widely used in aerospace, medical, industrial, and oil and gas industries.

We manufacture bars in accordance with international standards including ASTM B348, ASME SB348, and AMS 4921. Available in diameters ranging from 3 mm to 300 mm, our products can be supplied in hot-rolled, forged, or precision-ground finishes according to customer requirements.

Product Specifications

1. Grade: Gr2 and other grade gr5,gr7,gr9, gr12 can be customized

2. Size: Dia(6mm-350mm)*Length or Customized

3. Standard: ASTMB348,ASTM F67,ASTM F136

4. Type: Round, Square, Hexagon

5. Processing method: Forged and Rolled

6. Package Terms: Moisture-proof cloth, foam cotton inside, wooden case outside. 8.

7. Shipping Terms: Express,Air,Shipping or as your choice.

8.Payment terms: 30% TT prepayment ,70% balance before shipment or LC

| Property | Unit | Typical Value |

|---|---|---|

| Density | g/cm³ | 4.51 |

| Tensile Strength | MPa | ≥ 345 |

| Yield Strength | MPa | ≥ 275 |

| Elongation | % | ≥ 20 |

| Hardness | HB | ≤ 160 |

| Modulus of Elasticity | GPa | 105 |

Features of Grade 2 titanium round bar

* Low Density and High Specification Strength

* Excellent Corrosion Resistance

* Good Resistance to Effect of Heat

* Excellent Bearing to Cryogenics Property

* Nonmagnetic and Non-toxic

* Good Thermal Properties

* Low Modulus of Elasticity

Manufacturing & Processing Capability

Our production process integrates advanced melting, forging, rolling, and precision machining technologies. Using vacuum arc remelting (VAR) and hot isostatic pressing (HIP) ensures high material purity and structural uniformity. Each bar is straightened, descaled, and ultrasonically tested to meet strict dimensional and mechanical standards.

We also provide custom machining services, including centerless grinding, threading, drilling, and polishing, enabling the material to be delivered in a ready-to-use state for immediate fabrication or assembly.

|

|

|

|

|

|

|

|

Surface & Mechanical Performance

The Grade 2 Titanium Round Bar features a smooth surface with low roughness values (Ra ≤ 0.8 μm), enhancing fatigue strength and corrosion protection. Its mechanical properties remain stable across a wide temperature range.

Surface finishes are available in pickled, polished, ground, or machined forms according to customer requirements.

Quality Assurance

All titanium bars are produced under a strict ISO 9001-certified quality management system. Each step — from raw material sourcing to final inspection — is traceable and documented. Non-destructive tests such as ultrasonic testing (UT) and eddy current testing (ECT) are performed to ensure internal soundness. Chemical composition and mechanical properties are verified in accordance with ASTM and EN standards, and mill test certificates (MTC) are provided with every shipment.

Application Advantages

The Grade 2 Titanium Round Bar offers exceptional versatility across demanding industries. Its advantages include:

- Superior resistance to seawater, chlorides, and oxidizing acids

- Excellent weldability and cold-forming characteristics

- Non-toxic and biocompatible properties for medical use

- Long service life in high-corrosion or high-stress environments

- Lightweight structure that reduces overall equipment mass

Typical applications include heat exchangers, condenser tubing, marine fasteners, pressure vessels, chemical reactors, orthopedic implants, and aerospace fittings.

Be used in a wide range of industries.

Metallurgy and Special Steel

Electronics and Semiconductors

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

R&D and Customization

Our R&D team continuously develops process innovations to enhance material purity, consistency, and surface finish. We offer full OEM and customization support, including:

- Tailored chemical composition or grain structure for specific environments

- Dimensional customization (length, diameter, tolerance)

- Surface treatment and coating solutions

- Small-batch prototyping for specialized industries

Packaging & Logistics

Every bar is carefully protected to prevent mechanical damage or surface oxidation during transportation. Standard export packaging includes plastic film wrapping, foam protection, and wooden cases or pallets.

We cooperate with reliable international logistics partners to guarantee fast and safe global delivery. Custom labeling, palletization, and container loading plans are available according to customer or project needs.

|

|

|

|

|

|

|

|

|

|

|

|

Global Cooperation& Certification

Our Grade 2 Titanium Round Bar products are exported to over 40 countries, serving customers in Europe, North America, the Middle East, and Asia-Pacific. The company holds certifications including ISO 9001, ISO 13485, and CE compliance for medical and industrial titanium materials.

Long-term partnerships with aerospace, petrochemical, and medical enterprises demonstrate our commitment to quality, precision, and customer trust.

|

|

|

|

|

|

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email