- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

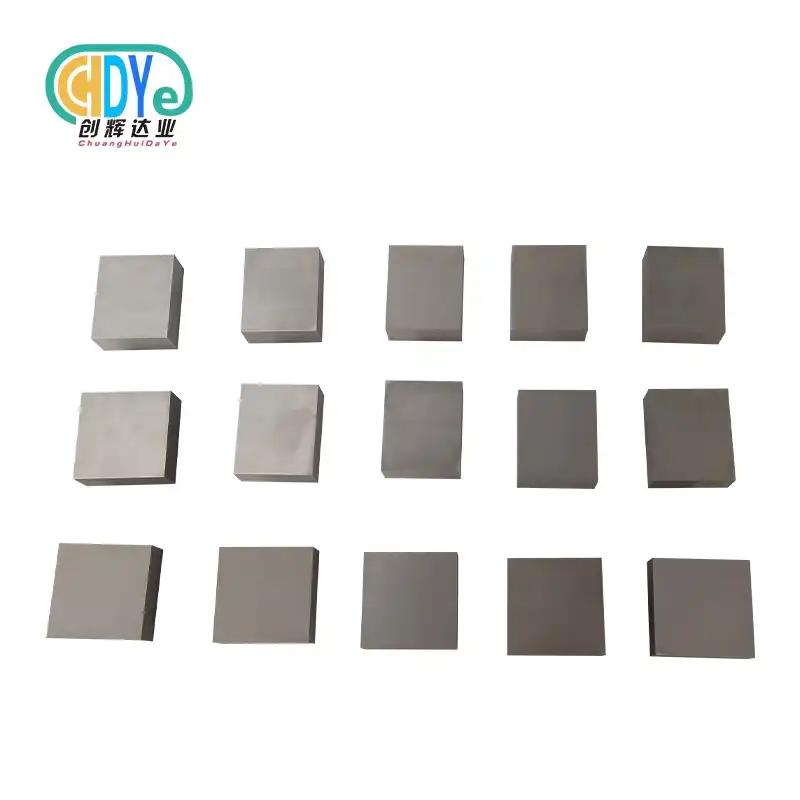

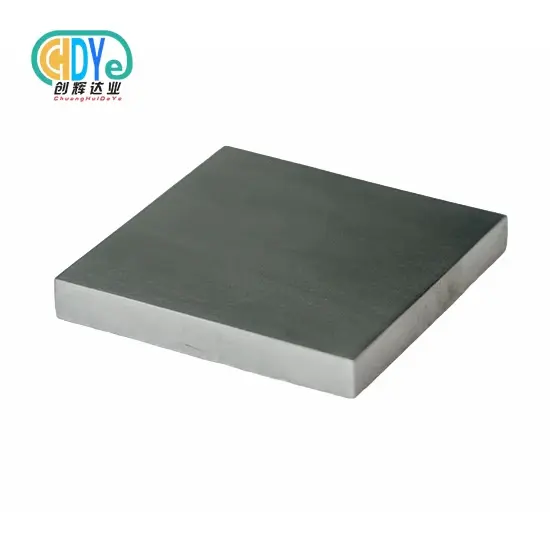

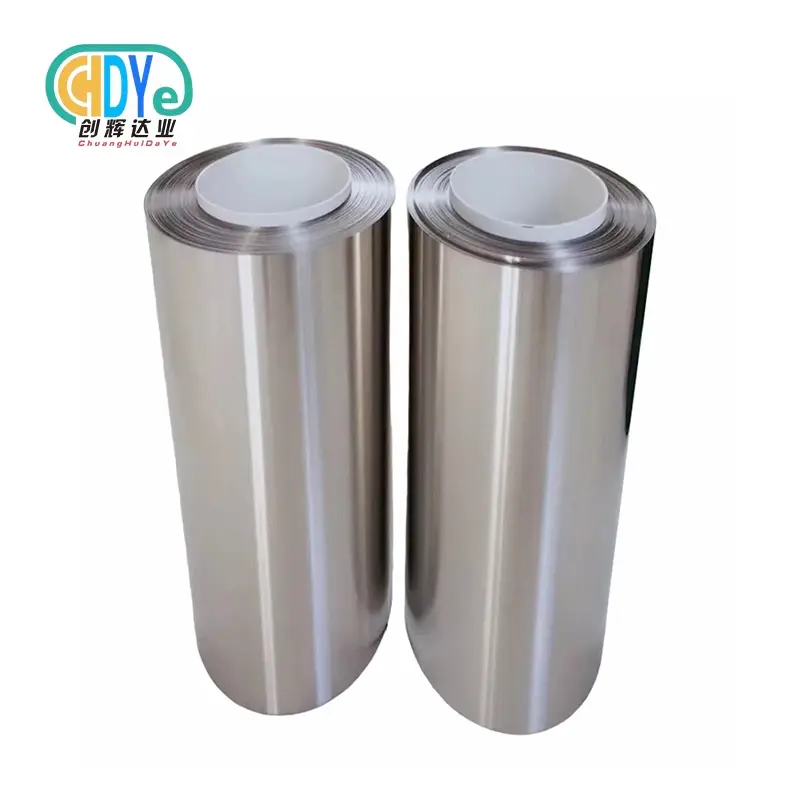

Pure Niobium Sheet

Product Introduction

The Pure Niobium Sheet offered by Shaanxi Chuanghui Daye Metal Material Co., Ltd. is crafted from high-purity niobium, providing exceptional corrosion resistance, thermal stability, and mechanical strength. Each Pure Niobium plate undergoes precision rolling and annealing processes to ensure uniform thickness, smooth surfaces, and optimal ductility. This makes the Pure Niobium plate an ideal choice for advanced industrial applications where reliability and performance are critical.

Pure niobium sheet is a high melting point, high strength metal material with good high temperature durability and thermoelectric stability.

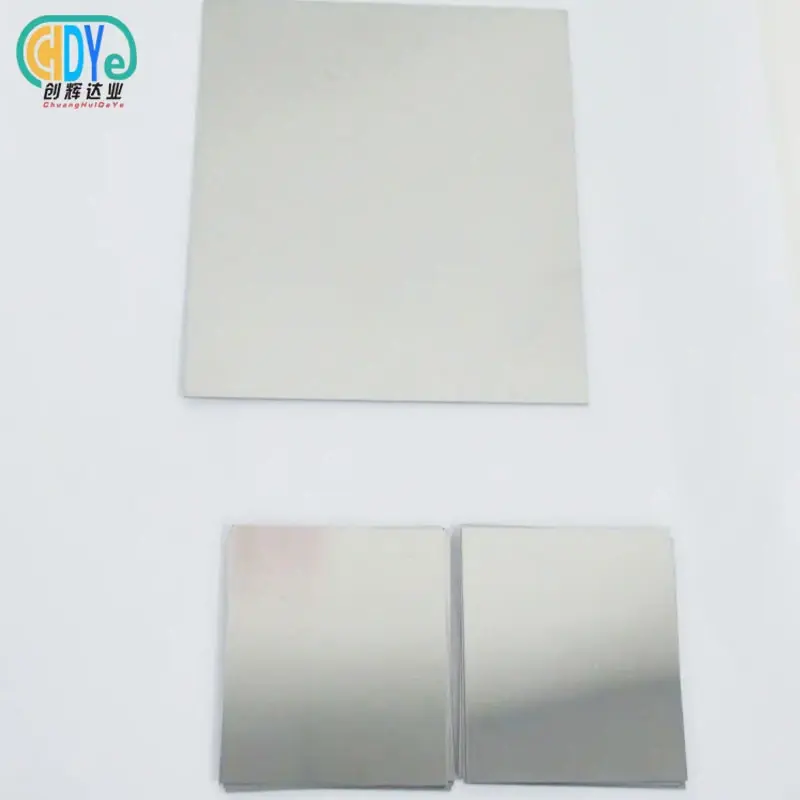

|

Purity |

99.9% |

|

Technics |

Cold rolled |

|

Standard |

ASTM B393 / ASME SB393 |

|

Density |

8.57g/cm3 |

|

Application |

Industrial |

|

Specification |

Customized |

|

Hardness |

Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. |

|

Certification |

ISO 9001:2015 |

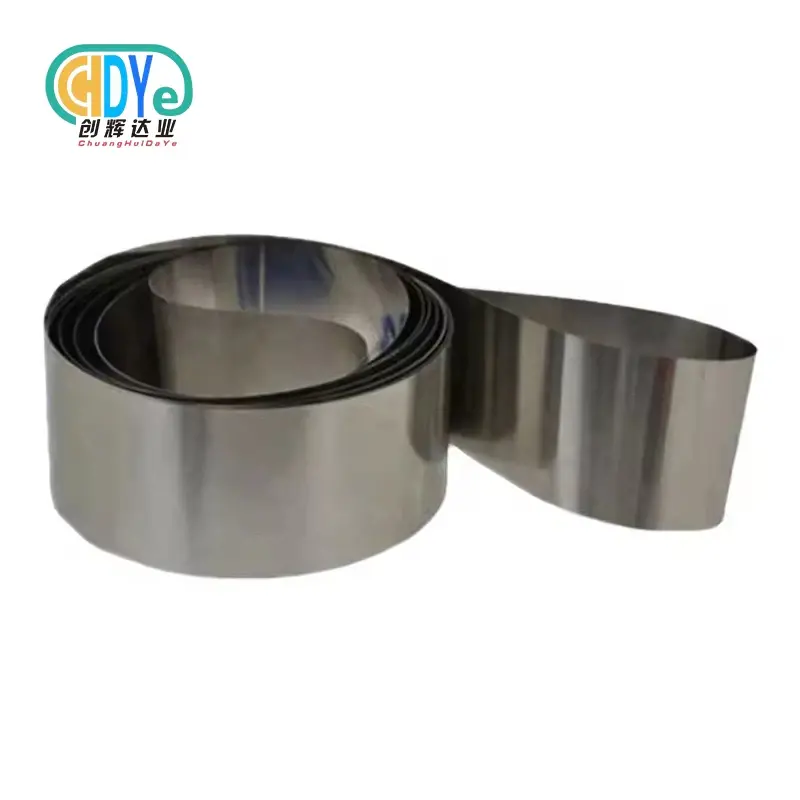

Pure niobium sheet features

Pure Niobium sheets are manufactured through a cold rolling process. As a result, it has a chemically pure surface for different reactive applications-high-end applications such as synthetic diamond manufacturing, sputtering targets for fibre optic use, and others.

UNS R04210 grade pure Niobium sheet is utilized in nuclear reactors as well as in particle accelerators. In addition, these are utilized in the manufacturing of nickel-based superalloy and superconductors. These alloy sheets can be available in different grades and specifications and are widely used in different industries, including:

Industrial Synthetic Diamonds processing

Superconductor

Thin Film Coatings for Glass and Fiber Optics

Nuclear Reactor unit

Jewelry industry

Nuclear reactors

Gas pipelines

Supercollider

Jet engines

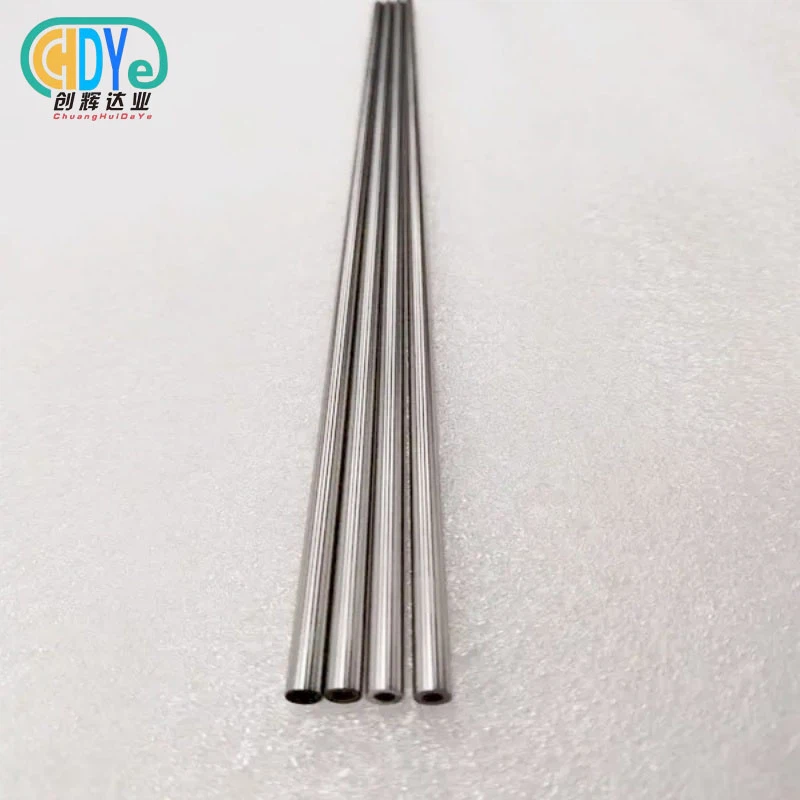

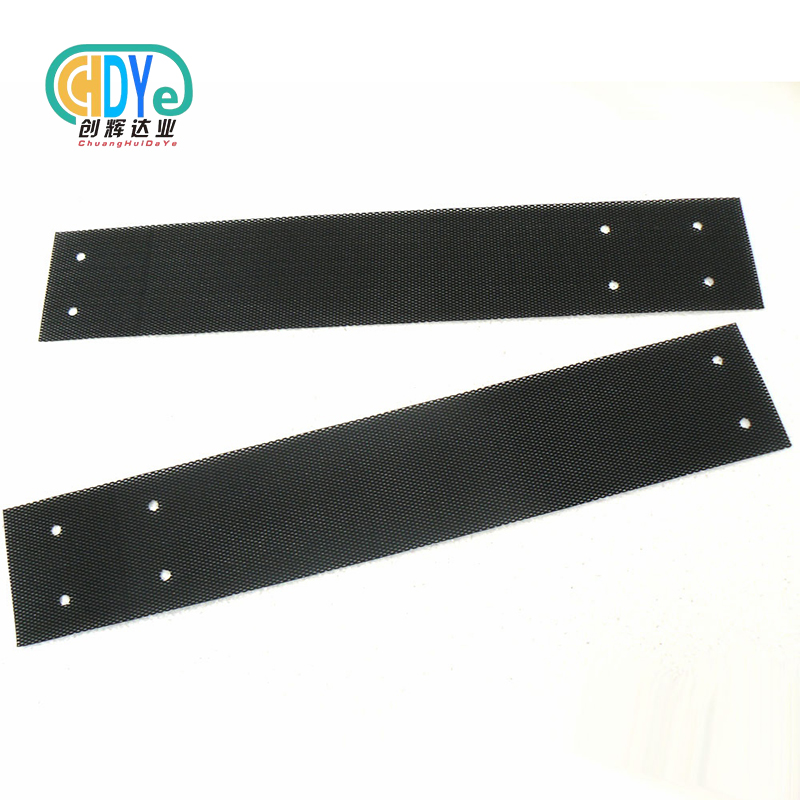

Related Niobium Products

Application Advantages

1. Aerospace: Niobium sheets are used to manufacture engine, combustion chamber, duct and other parts, taking advantage of their high melting point, corrosion resistance and high strength properties.

2. Electronic components: used in the manufacture of electronic components such as semiconductors, capacitors, resistors, etc., taking advantage of their good conductivity and plasticity.

3. Automobile manufacturing: used in engine parts, exhaust pipes and other parts that are subject to high temperature ablation

4. Chemical industry: manufacturing corrosion-resistant storage tanks, heat exchangers, reactors and other equipment

Medical devices: used in artificial joints, dental implants, pacemakers and other medical devices

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

The production of Pure Niobium Sheet follows a rigorous process:

- Raw Material Selection: High-purity niobium ingots are carefully chosen.

- Vacuum Melting: Ensures homogeneity and removes impurities.

- Hot Rolling & Forging: Converts ingots into preliminary sheet forms.

- Cold Rolling & Annealing: Enhances mechanical properties and surface finish.

- Precision Finishing: Achieves exact thickness tolerances and smooth surfaces.

- Final Inspection: Prepares the Pure Niobium Sheet for packaging and delivery.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Every Pure Niobium Sheet undergoes comprehensive quality control measures:

- Chemical Composition Analysis to ensure material purity

- Mechanical Testing including tensile strength and elongation

- Dimensional Checks for thickness, width, and flatness

- Surface Inspection to detect scratches, pits, or defects

- Non-Destructive Testing for internal flaws

These steps ensure that every Pure Niobium Sheet meets the highest industry standards.

R&D and Customization

Our R&D team provides tailored solutions for Pure Niobium Sheet, including:

- Custom sizes, thicknesses, and surface finishes

- Alloy optimization for specialized applications

- Prototype and small-batch production

- Material selection guidance and technical consultation

Continuous innovation allows us to deliver Pure Niobium Sheet that fits unique industry requirements.

Packaging & Global Logistics

The Pure Niobium Sheet is carefully packaged to prevent damage during transport:

- Wrapped in vacuum or anti-rust film

- Supported with foam or wooden braces to avoid deformation

- Secured in export-standard wooden crates with clear product labeling

- Shipped via reliable air, sea, or land logistics to over 50 countries

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Shaanxi Chuanghui Daye provides complete OEM and customization services for Pure Niobium Sheet:

- Tailored widths, thicknesses, and surface treatments

- Prototype, small-batch, or large-scale production

- Technical guidance and after-sales support

- Solutions for various industrial and high-tech applications

Every Pure Niobium Sheet is manufactured to meet exact customer specifications.

Inspection Process

The inspection workflow for Pure Niobium Sheet includes:

- Incoming Material Verification

- In-Process Monitoring during rolling, annealing, and finishing

- Intermediate Thickness & Surface Checks

- Mechanical & Chemical Testing

- Final Packaging Inspection

This ensures that each Pure Niobium Sheet is traceable and quality-assured.

Why Choose Us

- 30+ Years of Expertise in rare metal materials

- ISO 9001:2015 Certified quality management system

- Advanced Equipment including electron beam furnaces and rolling machines

- 7-Day Fast Delivery for standard specifications

- Global Export Network covering over 50 countries

- OEM & Technical Services for custom solutions

Choosing Chuanghui Daye guarantees reliable, high-performance Pure Niobium Sheet backed by professional support.

|

|

|

|

|

|

FAQs

Q1: What standards does Pure Niobium Sheet comply with?

A1: All sheets are produced according to ASTM, ISO, and international specifications.

Q2: Can I order custom sizes and thicknesses?

A2: Yes, we provide full customization for Pure Niobium Sheet.

Q3: How is quality ensured?

A3: Through chemical analysis, mechanical testing, surface inspection, and non-destructive testing.

Q4: What is the lead time for Pure Niobium Sheet?

A4: Standard sheets ship within 7 days; custom orders vary based on specifications.

Q5: Do you offer international shipping?

A5: Yes, reliable air, sea, and land logistics are available worldwide.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email