- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

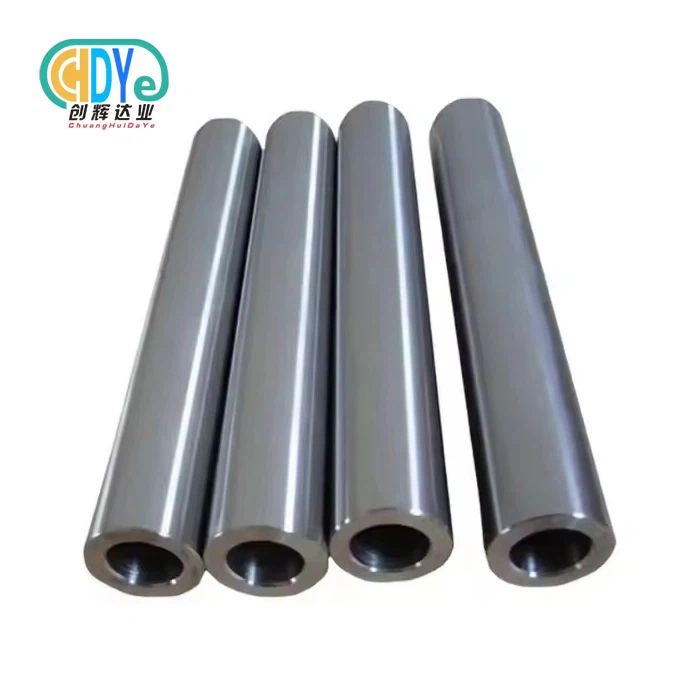

Tantalum alloy rod

2. Diameter: 1–50 mm

3. Length: 1000-3000 mm or customized

4. Density: 16.7–17.0 g/cm³

5. Tensile strength: 250–400 MPa

6. Applications: Aerospace, chemical

7. Corrosion resistant

Product Introduction

Our tantalum alloy rod delivers exceptional corrosion resistance and strength for critical industrial uses. Manufactured in China's "Titanium Capital," these precision-engineered rods combine tantalum with niobium or tungsten to create superior alloys. You'll find our products perfect for aerospace, chemical processing, and high-temperature applications where reliability matters most. With over 30 years of industry expertise, we ensure every rod meets the highest quality standards for your specific requirements.

Key Features and Benefits

Our tantalum alloy products offer outstanding advantages for your projects:

- Superior Corrosion Resistance: Outperforms stainless steel in harsh chemical environments

- High-Temperature Stability: Maintains strength and integrity at extreme temperatures

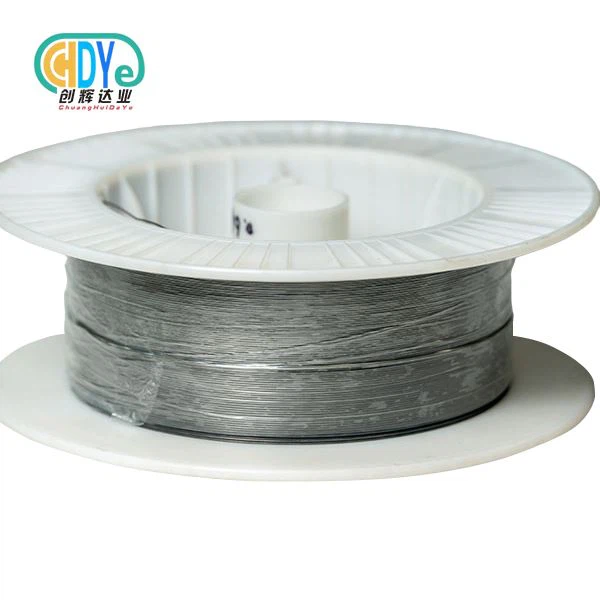

- Excellent Ductility: Can be drawn into fine wires or shaped for custom applications

- Biocompatibility: Safe for medical and surgical instrument manufacturing

- Long Service Life: Reduces maintenance costs and downtime

- Precision Manufacturing: Consistent quality and dimensional accuracy

Technical Specifications

| Property | Value |

|---|---|

| Alloy Types | Ta-Nb, Ta-W |

| Diameter Range | 1-50 mm |

| Maximum Length | 1000 mm |

| Density | 16.7-17.0 g/cm³ |

| Tensile Strength | 250-400 MPa |

| Melting Point | 2900-3000°C |

| Thermal Conductivity | 57 W/m·K |

Chemical Composition

|

Grade |

Chemical Composition (≤%) |

||||||||||||

|

Ta |

Fe |

Si |

Ni |

W |

Mo |

Ti |

Nb |

O |

C |

H |

N |

||

|

Ta1 |

Bal. |

0.005 |

0.005 |

0.002 |

0.01 |

0.01 |

0.002 |

0.03 |

0.015 |

0.01 |

0.0015 |

0.01 |

|

|

Ta2 |

Bal. |

0.03 |

0.02 |

0.005 |

0.04 |

0.03 |

0.005 |

0.1 |

0.02 |

0.01 |

0.0015 |

0.01 |

|

|

TaNb3 |

Bal. |

0.03 |

0.03 |

0.005 |

0.04 |

0.03 |

0.005 |

<3.5 |

0.02 |

0.01 |

0.0015 |

0.01 |

|

|

TaNb20 |

Bal. |

0.03 |

0.03 |

0.005 |

0.04 |

0.03 |

0.005 |

17.0-23.0 |

0.02 |

0.01 |

0.0015 |

0.01 |

|

|

Ta2.5W |

Bal. |

0.005 |

0.005 |

0.002 |

3.0 |

0.01 |

0.002 |

0.04 |

0.015 |

0.01 |

0.0015 |

0.01 |

|

|

Ta10W |

Bal. |

0.005 |

0.005 |

0.002 |

11 |

0.01 |

0.002 |

0.04 |

0.015 |

0.01 |

0.0015 |

0.01 |

|

Physical properties

|

Grade(UNS) |

Annealed |

||

|

Tensile strength min,psi (MPa) |

Yield strength min,psi (MPa)(2%) |

Elongation min,% (1 inch gage length) |

|

|

Pure Ta (RO5200,RO5400) |

30000 (207) |

20000 (138) |

20 |

|

Ta-10W (RO5255) |

70000 (482) |

60000 (414) |

15 |

|

Ta-2.5W (RO5252) |

40000 (276) |

30000 (207) |

20 |

Available Grades and Materials

We offer various tantalum alloy compositions to meet your specific needs:

- Ta-Nb Alloys: Enhanced ductility and workability

- Ta-W Alloys: Superior high-temperature strength

- Custom Compositions: Tailored to your application requirements

Each grade undergoes strict quality control to ensure consistent performance across all manufacturing batches.

Manufacturing Process

Our advanced production process ensures superior quality:

- Raw Material Selection: High-purity tantalum sourced from certified suppliers

- Alloying: Precise mixing with niobium or tungsten in controlled atmospheres

- Cold Working: Forging, rolling, and drawing to achieve desired dimensions

- Heat Treatment: Optimized annealing for enhanced properties

- Quality Testing: Comprehensive inspection and testing protocols

|

|

|

|

|

|

|

|

Applications and Industries

Your tantalum alloy rod finds applications across multiple industries:

- Aerospace: Jet engine components and missile parts

- Chemical Processing: Heat exchangers and reaction vessels

- Medical Devices: Surgical instruments and orthopedic implants

- Electronics: High-performance capacitor manufacturing

- Nuclear Industry: Reactor components and radiation shielding

- Oil & Gas: Corrosion-resistant equipment for harsh environments

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

We maintain strict dimensional control for all products:

- Diameter Tolerance: ±0.05mm for diameters under 10mm

- Length Tolerance: ±2mm for standard lengths

- Straightness: Better than 0.5mm per meter

- Surface Finish: Ra 0.8-1.6 μm standard

Custom tolerances available upon request to meet your specific requirements.

Product Features in Detail

The exceptional properties of our tantalum alloys make them ideal for challenging applications. The naturally occurring oxide film provides unmatched corrosion resistance, similar to glass in most environments. You'll appreciate the material's ability to withstand sulfuric acid, hydrochloric acid, and various organic compounds without degradation.

Temperature resistance sets our tantalum alloy rod apart from conventional materials. While maintaining structural integrity at extreme temperatures, these rods offer reliable performance in thermal cycling applications. The ductile nature allows for complex forming operations without cracking or failure.

Quality Assurance and Testing

Every product undergoes comprehensive testing:

- Chemical Analysis: Verified composition using spectroscopy

- Mechanical Testing: Tensile strength and hardness verification

- Dimensional Inspection: Precise measurement of all critical dimensions

- Surface Quality: Visual and microscopic examination

- Certification: Material certificates provided with each shipment

|

|

|

OEM & Customization Services

We understand your unique requirements. Our engineering team works closely with you to develop custom solutions including:

- Special alloy compositions

- Non-standard dimensions

- Custom surface treatments

- Specialized packaging requirements

- Technical support and consultation

Packaging and Shipping

Your orders receive careful handling throughout the shipping process:

- Protective Packaging: Foam padding and wooden crates for safe transport

- Global Shipping: Delivered to over 50 countries worldwide

- Documentation: Complete shipping and material certificates

- Insurance: Full coverage for international shipments

- Tracking: Real-time shipment monitoring available

|

|

|

|

|

|

|

|

|

Why Choose Us

With three decades of rare metal industry experience, we bring unmatched expertise to every project. Located in Baoji High-tech Development Zone, our facility benefits from China's premier titanium and rare metal infrastructure. You'll receive competitive pricing, on-time delivery, and personalized service from our dedicated team.

Our commitment to quality and customer satisfaction has earned trust from clients across the United States, Germany, South Korea, Singapore, and beyond. We focus on building long-term partnerships through reliability, honesty, and continuous improvement.

|

|

|

|

|

|

FAQs

Q: What's the minimum order quantity?

A: We accommodate both small prototype orders and large production runs.

Q: Can you provide material certificates?

A: Yes, complete chemical and mechanical property certificates accompany each shipment.

Q: What's the typical lead time?

A: Standard products ship within 1-2weeks; custom specifications may require 2-3weeks.

Q: Do you offer technical support?

A: Our experienced engineers provide comprehensive technical assistance throughout your project.

Contact Us

Ready to discuss your tantalum alloy rod requirements? Our expert team stands ready to help you select the perfect solution for your application.

Email: info@chdymetal.com

Mobile./what's app: 86-18049386902

Contact us today for competitive pricing, technical specifications, and delivery information. Let's work together to bring your project to success with our premium tantalum alloy solutions.

Learn about our latest products and discounts through SMS or email