- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

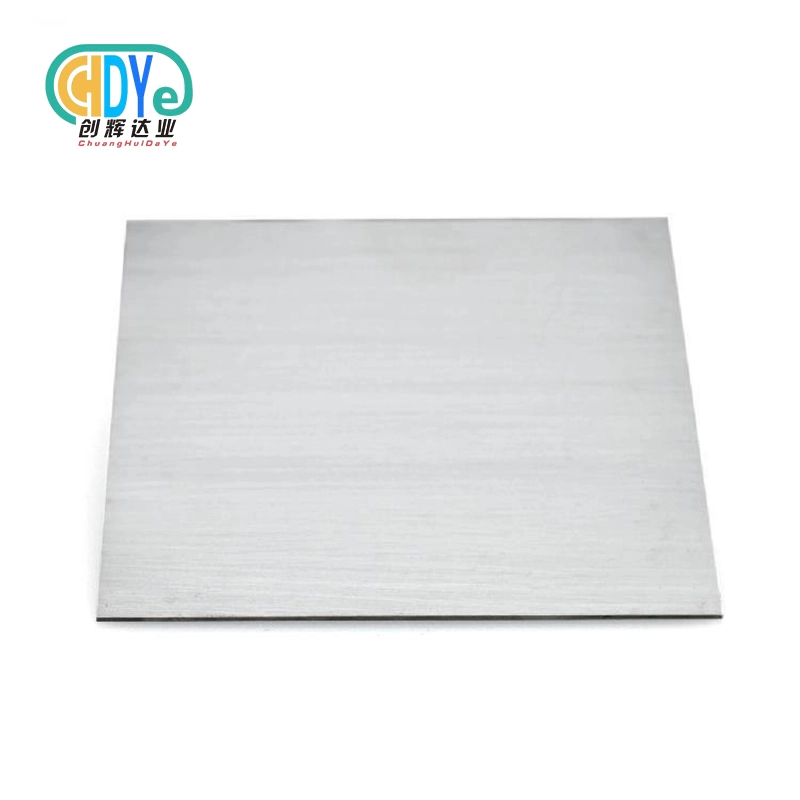

tantalum sheet and plate

2.Size: Thickness 0.5-20mm*width50-1200*Length30-2500mm

3.Standard: ASTM B708

4.Type: foil strip shape are all available

Product Introduction

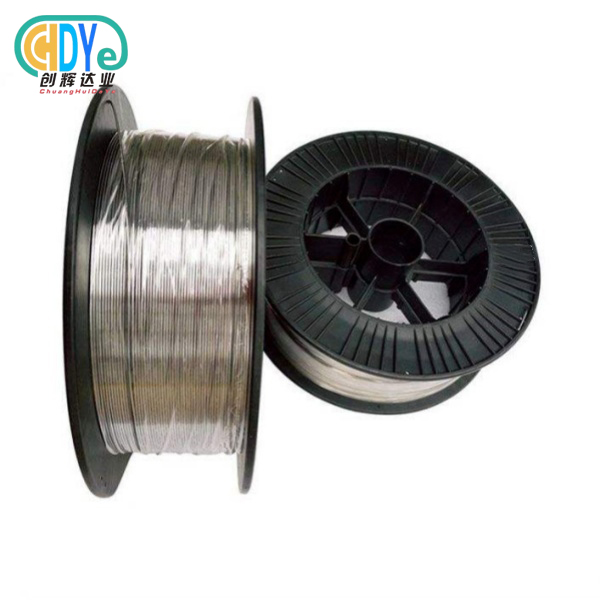

Looking for superior corrosion resistance and exceptional durability? Our tantalum sheet and plate products deliver unmatched performance across industrial applications. Manufactured with over 99.9% pure tantalum, these dark blue-gray metal sheets offer outstanding chemical inertness and high-temperature stability. Whether you need precision components for chemical processing equipment or specialized parts for aerospace applications, our tantalum products meet the most demanding specifications. Each sheet undergoes rigorous quality control to ensure consistent performance and reliability for your critical projects.

Key Features and Benefits

Our tantalum products stand out in the market for several compelling reasons. The exceptional corrosion resistance makes them ideal for harsh chemical environments. You'll appreciate the high melting point that enables use in extreme temperature conditions. The biocompatibility ensures safe use in medical applications. Plus, the excellent ductility allows for complex forming operations without cracking or failure.

Technical Specifications

| Property | Specification |

|---|---|

| Alloy Composition | Ta >99.9% |

| Thickness Range | 0.1–50 mm |

| Maximum Width | up to 1000 mm |

| Maximum Length | up to 3000 mm |

| Density | 16.65 g/cm³ |

| Tensile Strength | 200–300 MPa |

| Melting Point | 3017°C |

| Surface Finish | Bright, pickled, or as-rolled |

| Certificate | ISO 9001:2015 |

|

Standard |

ASTM B708 |

| Condition | Annealed |

| Delivery time | normal production time need 10-15 days |

| Payment term | 30%TT in advance, 70% balance before shipment |

Chemical Composition

|

Content, Max, Weight % |

||||

|

Element |

R05200 Uanlloyed Tantalum |

R05255 90% Tantalum 10% Tungsten |

R05252 97.5% Tantalum 2.5% Tungsten |

R05240 60% Tantalum 40% Niobium |

|

C |

0.010 |

0.010 |

0.010 |

0.010 |

|

O |

0.015 |

0.015 |

0.015 |

0.020 |

|

N |

0.010 |

0.010 |

0.010 |

0.010 |

|

H |

0.0015 |

0.0015 |

0.0015 |

0.0015 |

|

Fe |

0.010 |

0.010 |

0.010 |

0.010 |

|

Mo |

0.020 |

0.020 |

0.020 |

0.020 |

|

Nb |

0.100 |

0.100 |

0.50 |

35.0~42.0 |

|

Ni |

0.010 |

0.010 |

0.010 |

0.010 |

|

Si |

0.005 |

0.005 |

0.005 |

0.005 |

|

Ti |

0.010 |

0.010 |

0.010 |

0.010 |

|

W |

0.05 |

9.1~11.0 |

2.0~3.5 |

0.050 |

|

Ta |

Remainder |

Remainder |

Remainder |

Remainder |

Available Grades and Materials

We supply various tantalum grades to meet your specific requirements. Our standard offering includes commercial pure tantalum with 99.9% minimum purity. For specialized applications, we can provide tantalum-tungsten alloys that offer enhanced strength properties. All materials comply with international standards including ASTM B708 and ASTM B365.

Manufacturing Process

Our production process begins with high-quality tantalum ingots. We use advanced rolling techniques to achieve precise thickness control. The material undergoes controlled annealing to optimize mechanical properties. Each step includes careful temperature monitoring and contamination prevention. Final inspection ensures dimensional accuracy and surface quality meet your specifications.

|

|

|

|

|

|

|

|

Applications and Industries

Tantalum sheet and plate find extensive use across multiple industries. Chemical processing plants rely on tantalum for reactor vessels and heat exchangers. The electronics industry uses these materials for sputtering targets and capacitor components. Medical device manufacturers choose tantalum for implants and surgical instruments. Aerospace companies incorporate tantalum into high-temperature engine components.

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

We maintain tight dimensional tolerances to ensure your components fit perfectly. Thickness tolerance is typically ±0.02mm for sheets under 1mm thick. Width and length tolerances are ±2mm for standard sizes. Custom dimensions are available with specific tolerance requirements upon request. Our precision cutting capabilities ensure clean edges and accurate dimensions.

Product Features in Detail

The unique properties of tantalum make it exceptional for demanding applications. Its corrosion resistance surpasses most metals, including resistance to acids, alkalis, and organic compounds. The high density provides excellent radiation shielding properties. Tantalum maintains strength at elevated temperatures where other metals fail. The material exhibits excellent thermal conductivity for heat transfer applications.

Quality Assurance and Testing

Every batch undergoes comprehensive testing to verify composition and properties. We perform chemical analysis using advanced spectroscopic methods. Mechanical testing includes tensile strength and hardness measurements. Surface quality inspection ensures defect-free products. All testing results are documented and provided with material certificates.

|

|

|

OEM & Customization Services

We understand that standard sizes don't always meet your needs. Our customization services include precision cutting to your exact dimensions. We offer various surface treatments including polishing and chemical etching. Special packaging requirements can be accommodated for sensitive applications. Our technical team works closely with you to develop optimal solutions.

Packaging and Shipping

Your tantalum sheet and plate products receive careful packaging to prevent damage during transit. We use protective wrapping and rigid containers for larger pieces. International shipping documentation is handled professionally. Our logistics team coordinates delivery timing to meet your project schedules. Special handling requirements are accommodated as needed.

Transaction Process

First contact us to confirm the grade, size quantity and standard you need, we check the stock size if we have then will provide you formal invoice to confirm, meanwhile you should arrange 30% prepayment and we preparing for the quick delivery, then we will take a photo of the actual weight of tantalum plate, you arrange the balance payment,when we receive your full payment the good will be picked up by express After 5-7 days you will receive them. And for the important the material certificate will be provided to you.

Why Choose Us

Shaanxi Chuanghui Daye Metal Material brings over 30 years of rare metal expertise to every order. Located in China's "Titanium Capital," we have access to premium raw materials and advanced processing facilities. Our products serve customers in over 50 countries worldwide. We combine competitive pricing with reliable quality and on-time delivery.

1. Rich experience in metal industry and we can give you professional advice when you choose in your application

2. Chdymetal can cut to precise dimensions with very tight tolerances. Rather than ordering big sheets and cutting the material yourself, let us do the cutting for you and reduce your risk and scrap.

3. Stock products with various grade and size, we can arrange quick delivery.

|

|

|

|

|

|

FAQs

Q: What is the minimum order quantity?

A: We accommodate both small prototype quantities and large production runs.

Q: Can tantalum be welded?

A: Yes, tantalum can be welded using appropriate techniques in controlled atmospheres.

Q: How does tantalum compare to stainless steel?

A: Tantalum offers superior corrosion resistance and higher temperature capability than stainless steel.

Q: What lead times should I expect?

A: Standard products typically ship within 1-2 weeks, custom orders may require 2-3 weeks.

Contact Us

Ready to discuss your tantalum requirements? Our technical team is here to help you select the right tantalum sheet and plate specifications for your application. Contact us today at info@chdymetal.com for detailed quotations and technical support. We look forward to becoming your trusted partner for high-quality tantalum solutions.

Learn about our latest products and discounts through SMS or email