- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

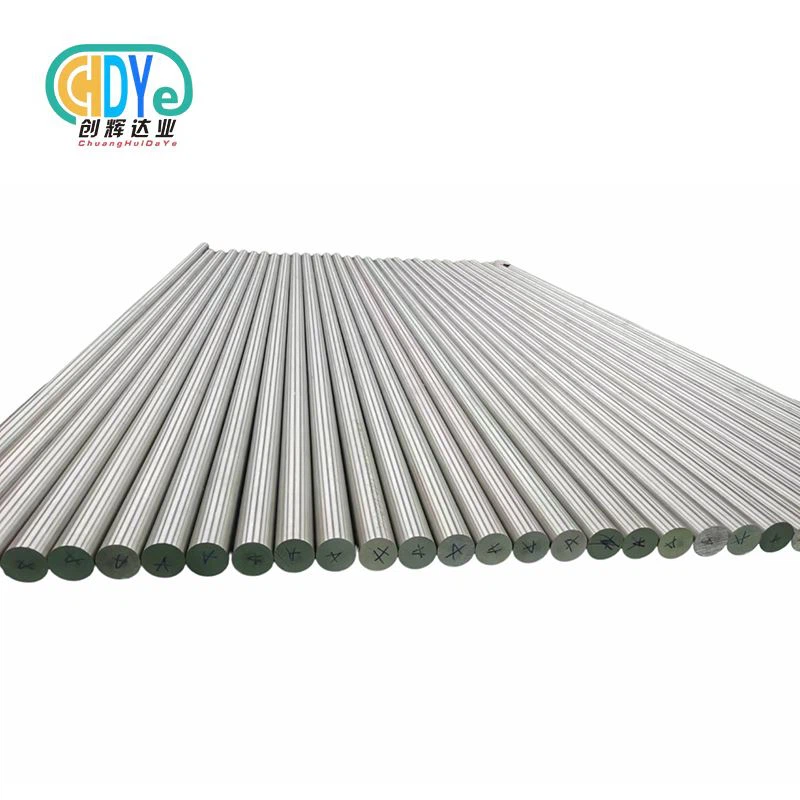

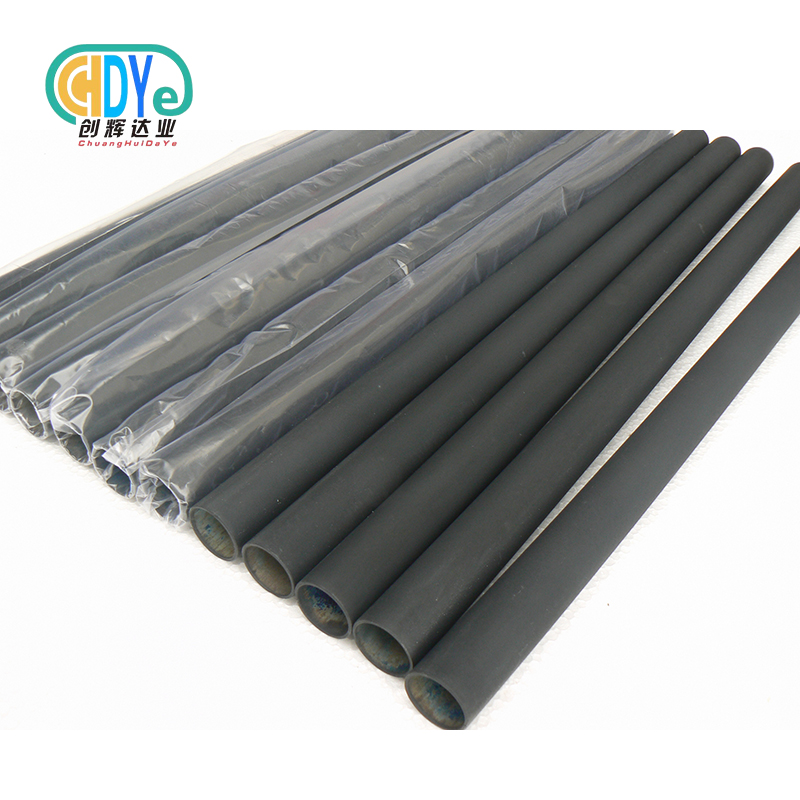

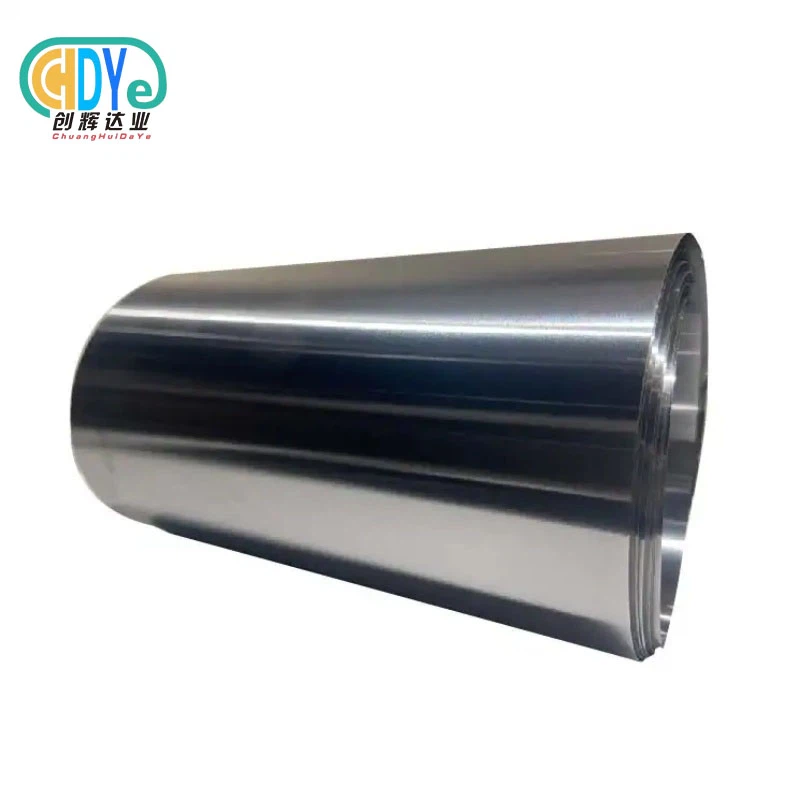

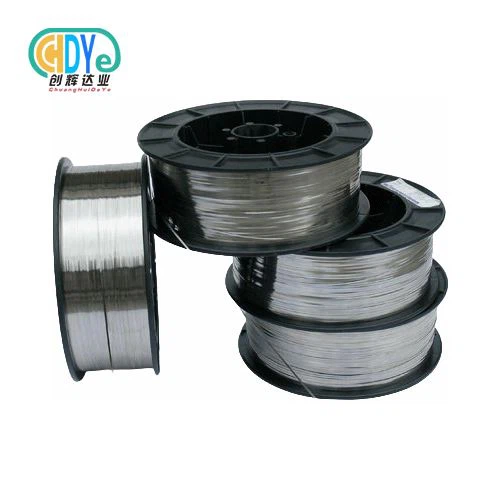

Molybdenum Wire And Rod

Product Introduction

The Molybdenum Wire And Rod supplied by Shaanxi Chuanghui Daye Metal Material Co., Ltd. is a premium refractory material product designed for applications requiring exceptional strength, thermal stability, and electrical conductivity. Produced using high-purity molybdenum powder, the wire and rod exhibit outstanding resistance to high temperatures, corrosion, and wear. With precise dimensions and uniform microstructure, Molybdenum Wire And Bar products are widely used in metallurgical, electronic, and aerospace industries. We manufacture both standard and custom specifications according to ASTM, ISO, and GB standards, ensuring superior quality and performance for critical industrial processes.

Molybdenum is silvery with a gray cast, has the sixth-highest melting point of any element. It freely forms stable hard carbides in alloys, and for this reason most of world production of the element (about 80%) is in making many types of steel alloys, including high strength alloys and super-alloys.Molybdenum wire and bar principally differ in gauge, or diameter and manufactured in the same techniques.Chdymetal provides high purity molybdenum wire and rod in many different elements.

Diameter: 0.1-3.0mm and customized

Features

High melting point

Good thermal conductivity and low thermal expansion performance

High intensity

Good conductivity and corrosion resistance

Application

Molybdenum wire can withstand high temperature and corrosion, it is used as heating materials of high-temperature resistance furnace, heating elements, automotive, aerospace, wire cutting machine;

With good electrical conductivity, molybdenum wire also can be applied to electronic tube socket, stent filament incandescent lamp, halogen lamps, discharge tube sealing material, lead-wire, tungsten filament with the mandrel, the grid.

There are some other common uses for molybdenum wire such as cathode, spray material.

Be used in a wide range of industries.

Steel industry

Electronic devices

Furnace components

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

The production of Molybdenum Wire And Rod involves multiple precision-controlled stages to ensure consistent quality and high performance:

Raw Material Preparation: Selection of high-purity molybdenum powder.

Isostatic Pressing: Compacting the powder to achieve uniform density.

Sintering: Conducted in a hydrogen or vacuum furnace to ensure purity and strength.

Hot Rolling & Forging: Enhances density and grain refinement for superior mechanical properties.

Drawing or Machining: Wire drawing or rod shaping to required dimensions.

Annealing: Stress relief to improve ductility and stability.

Final Inspection: Comprehensive testing before shipment.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Quality is at the heart of our production philosophy. All Molybdenum Wire And Rod products undergo rigorous testing to ensure consistency and performance:

Chemical Composition Test: Ensuring molybdenum purity ≥99.95%.

Mechanical Property Test: Evaluating tensile strength and elongation.

Dimensional & Surface Inspection: Confirming tolerance accuracy and surface smoothness.

Ultrasonic & Visual Examination: Detecting any internal or external defects.

Our ISO 9001:2015-certified quality management ensures every product delivered is 100% inspected and traceable.

R&D and Customization

Our R&D team focuses on continuous improvement and technical innovation in molybdenum-based materials. We provide customized Molybdenum Wire And Rod products in different diameters, lengths, surface finishes, and mechanical properties. Research areas include enhancing oxidation resistance, improving machinability, and developing new molybdenum alloys for specific environments. Custom machining, prototyping, and technical support services are available to meet diverse industry needs.

Packaging & Global Logistics

Each Molybdenum Wire And Rod is securely packaged to ensure safe transportation and storage:

Packaging Materials: Vacuum-sealed or anti-rust film wrapping, foam protection, and export-standard wooden boxes.

Labeling: Includes detailed specifications, grade, batch number, and inspection certificate.

Transportation Options: Reliable global logistics via air, sea, or land freight.

With more than 50 export markets, we guarantee safe, timely, and efficient delivery worldwide.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Shaanxi Chuanghui Daye offers comprehensive OEM and ODM services for Molybdenum Wire And Rod production. We provide:

Custom design and dimension support.

Prototype development and small-batch manufacturing.

Surface treatment and coating options.

Technical consultation and quality certification assistance.

With our flexible production and advanced equipment, we ensure fast lead times and competitive pricing for global clients.

Inspection Process

To maintain consistent product quality, every Molybdenum Wire And Rod passes through a strict inspection process:

Raw Material Inspection: Verify purity and grain uniformity.

Process Monitoring: Control temperature, pressure, and environment throughout production.

Final Testing: Physical, chemical, and mechanical evaluation before packaging.

Third-Party Verification: Available upon request for international clients.

This ensures that every delivery meets international standards and customer expectations.

Why Choose Us

30+ Years of Manufacturing Experience: Deep industry expertise in rare metal production.

ISO 9001:2015 Certification: Guaranteeing consistent and reliable product quality.

Advanced Equipment: Equipped with electron beam furnaces, rolling mills, and CNC machines.

Customization Flexibility: Tailored solutions for complex technical requirements.

Global Market Reach: Trusted by clients in over 50 countries for quality and service.

Choosing Chuanghui Daye means choosing excellence, reliability, and partnership in molybdenum products.

|

|

|

|

|

|

FAQs

Q1: What is the purity of your Molybdenum Wire And bar?

A1: The standard purity is ≥99.95%, with higher grades available upon request.

Q2: Can you provide customized dimensions?

A2: Yes, we produce molybdenum wire and bar in various diameters and lengths according to client drawings or standards.

Q3: What is the typical lead time?

A3: Standard production time is 7–10 days, depending on order volume and specifications.

Q4: Do you provide material certificates?

A4: Yes, each shipment includes test reports and certificates of conformity.

Q5: How do you ensure safe delivery?

A5: All products are securely packed in vacuum-sealed or wooden export boxes for global transportation.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email