- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Product Introduction

MMO anode tubular is a high-performance electrochemical anode material, using mixed metal oxide (MMO) coating technology, with excellent electrocatalytic activity, corrosion resistance and long life. It is widely used in cathodic protection, electrolysis industry, water treatment and chemical corrosion protection, and is an ideal choice to replace traditional anode materials.

Common size: Dia 19mm,25mmand 32mm Length: 1000mm/1200mm/1500mm customized

Production time: need about 7-15 days

Mmo anode tubular Product Features

1. High-efficiency electrocatalytic performance: MMO coating has high catalytic activity and significantly reduces electrolysis energy consumption.

2. Excellent corrosion resistance: Excellent performance in strong acid, strong alkali and high chloride ion environment, long service life.

3. Low consumption rate: extremely low coating consumption rate, reducing maintenance costs.

4. Lightweight design: titanium-based material is light in weight and easy to install and transport.

5. Environmental protection and energy saving: no pollution, low energy consumption, in line with green environmental protection requirements.

Application Advantages

The MMO Anode Tubular provides long-term corrosion resistance and superior electrochemical stability for cathodic protection systems. It is ideal for underground pipelines, storage tanks, marine structures, and reinforced concrete applications.

Cathode protection: used for corrosion protection of offshore platforms, ships, underground pipelines and storage tanks.

Electrolysis industry: chlor-alkali industry, electrolysis of water to produce hydrogen, electroplating and metal extraction.

Water treatment: sewage treatment, swimming pool disinfection and drinking water purification.

Chemical corrosion protection: used for anti-corrosion anodes in electrolytic cells, reactors and chemical equipment.

Be used in a wide range of industries.

Seawater electrolysis

Marine aquaculture

Chlor-alkali industry

Cathodic protection

Electroplating industry

Non-ferrous metal electrolytic extraction

Manufacturing & Process Flow

Shaanxi Chuanghui Daye adopts advanced production processes and precision coating technology to ensure optimal coating adhesion and uniformity.

Manufacturing Flow:

- Titanium Tube Selection: High-purity Gr1 or Gr2 titanium selected for dimensional accuracy and corrosion resistance.

- Surface Treatment: Degreasing, sandblasting, and chemical cleaning to ensure optimal surface activation.

- MMO Coating Application: Ruthenium–Iridium mixed metal oxide applied via thermal decomposition.

- Sintering Process: High-temperature sintering to form a dense, adherent coating layer.

- Inspection & Testing: Comprehensive quality checks for coating thickness, adhesion, and electrochemical performance.

- Final Assembly & Packaging: Anodes cut, welded, or pre-assembled according to customer requirements.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Every MMO Tubular Anode produced by Chuanghui Daye undergoes rigorous testing to meet ISO 9001:2015 standards.

Inspection Scope Includes:

- Raw material verification (titanium purity, surface integrity)

- Coating composition and adhesion testing

- Accelerated life testing in simulated electrolytic environments

- Electrical performance validation (potential and consumption rate)

- Final dimensional and visual inspection before packaging

Strict quality control ensures every MMO Tubular Anode meets global engineering standards.

R&D and Customization

Our R&D team continuously innovates in coating formulation, tubular geometry optimization, and anode performance enhancement.

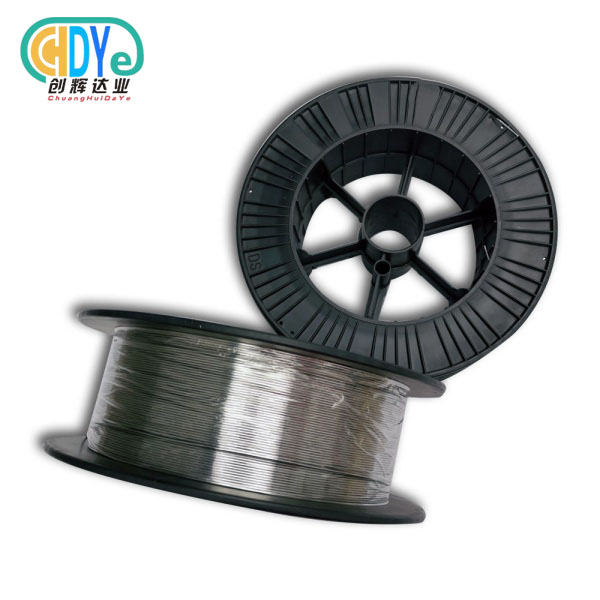

We offer full customization services including:

- Tailored tube dimensions (OD, length, wall thickness)

- MMO coating composition (Ru-Ir, Ir-Ta, or customized)

- Connection type (threaded, welded, or flanged)

- Current output and service life optimization

We also collaborate with global research partners to develop next-generation MMO anodes for renewable energy and advanced electrochemical systems.

Packaging & Global Logistics

To ensure product integrity during transport, all anodes are packaged according to international export standards.

Packaging Details:

- Vacuum-sealed or anti-rust film wrapping

- Foam and wooden crate protection

- Clear product labeling with specifications and batch numbers

Logistics Options:

- Air freight for urgent delivery

- Sea freight for bulk shipments

- Door-to-door express options for small orders

With partnerships in over 50 global markets, Shaanxi Chuanghui Daye guarantees safe and efficient delivery.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

We provide OEM and ODM support for global engineering firms, system integrators, and equipment manufacturers.

Our OEM Capabilities:

- Custom electrode assemblies and mounting designs

- Private labeling and branding

- Technical documentation and performance certification

- Flexible batch sizes and rapid production turnaround

Our engineering experts ensure all anodes are precisely tailored to meet system design and environmental conditions.

Inspection Process

Each anode is subjected to a strict multi-step inspection protocol before leaving the factory:

- Material Inspection – Verify titanium grade and chemical purity.

- Surface Pretreatment Inspection – Ensure complete cleanliness and activation.

- Coating Uniformity Test – Measure coating thickness and visual uniformity.

- Adhesion & Bonding Strength Test – Confirm coating stability after sintering.

- Electrochemical Performance Evaluation – Test current density, potential, and efficiency.

- Final Review & Packaging Inspection – Ensure all labeling and documentation are correct.

Why Choose Us

- 30+ Years of Rare Metal Expertise: Deep technical background and mature production system.

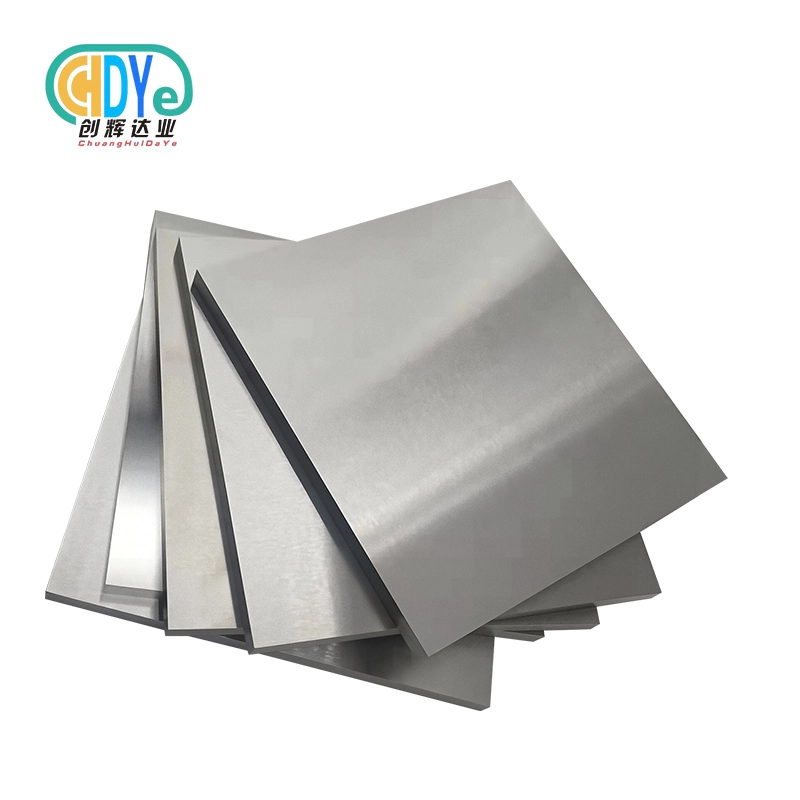

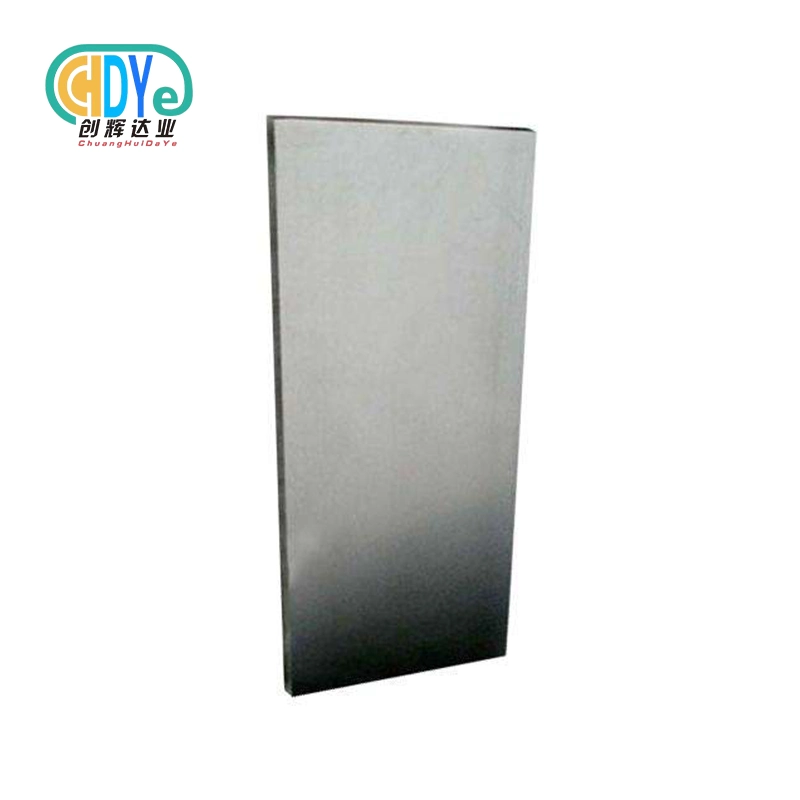

- Comprehensive Product Range: From titanium, niobium, tantalum to tungsten and molybdenum.

- Certified Quality: ISO 9001:2015 certified, full traceability in every batch.

- Global Export Experience: Supplying over 50 countries across Europe, America, and Asia.

- Strong Technical Support: Experienced engineers providing design and installation guidance.

- Fast Production & Delivery: Standard lead time within 7 days for common sizes.

|

|

|

|

|

|

FAQs

Q1: What is the expected service life of an MMO tubular anode?

A1: Typically 20–30 years, depending on coating type, current density, and environment.

Q2: Can you supply custom tube dimensions and coatings?

A2: Yes, we can produce according to customer drawings and required electrochemical performance.

Q3: What is the maximum operating temperature for the anode?

A3: Standard MMO tubular anodes can operate continuously up to 60–80°C.

Q4: What type of titanium substrate is used?

A4: Usually ASTM B338 Grade 1 or Grade 2 titanium, depending on mechanical requirements.

Q5: What industries use your MMO Anode Tubular products?

A5: Commonly used in oil & gas pipelines, offshore platforms, seawater intake systems, and concrete structures.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email