- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

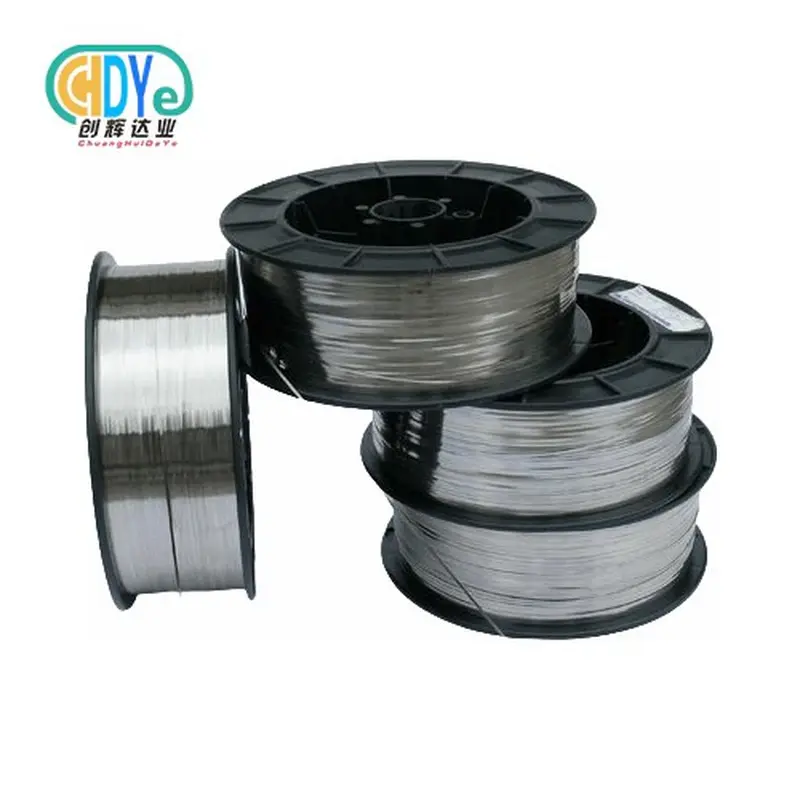

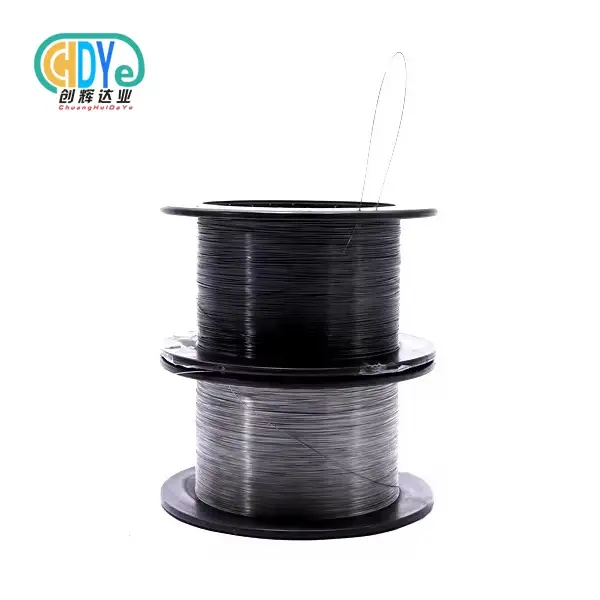

High Purity Niobium Wire

Product Introduction

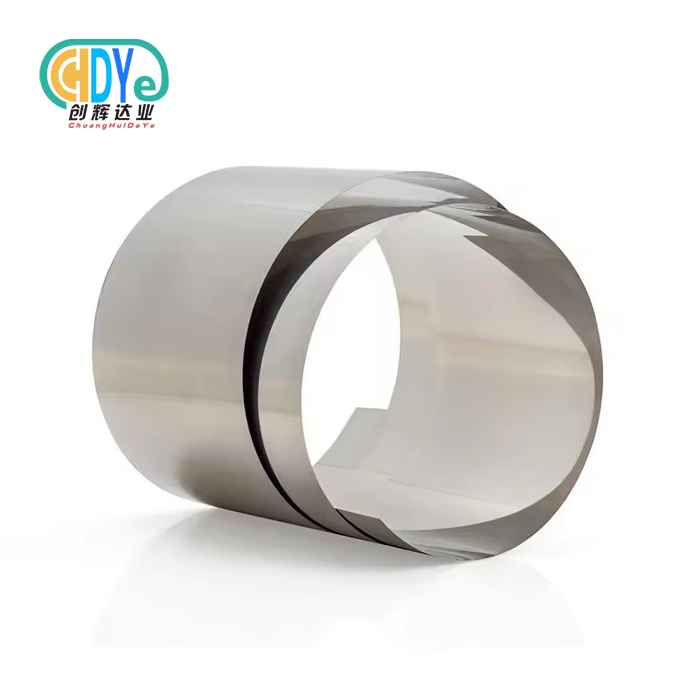

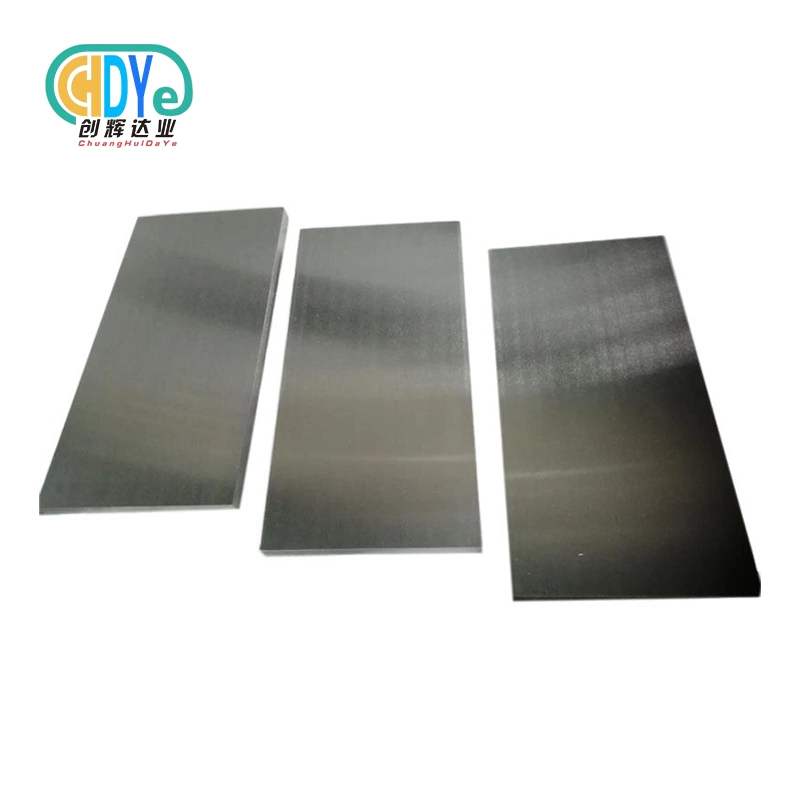

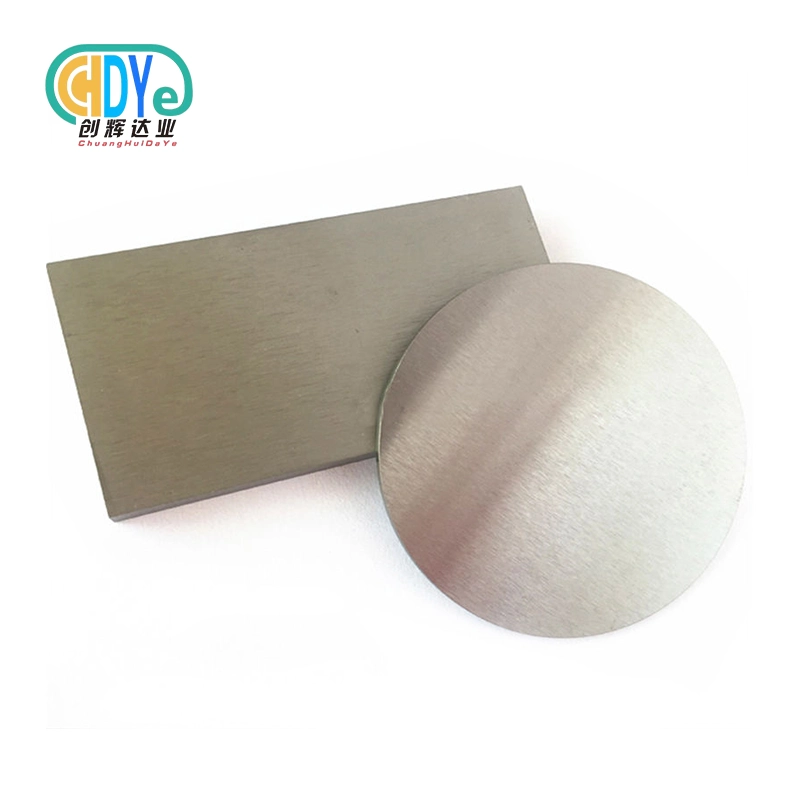

The High Purity Niobium Wire from Shaanxi Chuanghui Daye Metal Material Co., Ltd. is manufactured from premium-grade niobium, ensuring exceptional chemical purity and mechanical properties. With excellent corrosion resistance, high melting point, and outstanding ductility, this wire is ideal for applications in demanding industrial and high-tech environments. Each product is produced to meet ASTM, AMS, ISO, and GB standards, guaranteeing consistent quality and reliable performance. Our advanced production techniques ensure uniform diameter, smooth surface, and flexibility for both standard and custom specifications.

Chdymetal can offer high purity niobium wire with various purities and sizes. Niobium Wire, drawn from high-purity niobium rods, They have excellent properties such as high melting point, high strength, high electrical conductivity, high superconductivity, and high corrosion resistance.

|

Product Name |

High purity niobium wire |

|

Material |

RO4200, RO4210 |

|

Standard |

ASTM B362 |

|

Size |

0.3-3mm |

|

Service |

Customized OEM, OEM/ODM/Customized, ODM Available |

|

Packing |

Wooden box |

|

Delivery time |

Stock size will be 1-5 days,normal production time is about 15 days |

|

Payment terms |

30%TT in advance,70% balance before shipment |

|

Condition |

Annealed / unannealed |

|

Surface |

Cold rolling Bright |

Niobium and Niobium Alloy UNS Grade

UNS R04200 Reactor grade unalloyed niobium

UNS R04210 Commercial grade unalloyed niobium

UNS R04251 Reactor grade Niobium-1% zirconium

UNS R04261 Commercial grade Niobium-1% zirconium

High purity Niobium wire Application

1. Superconducting materials

2. Electronic components

3. High-temperature materials

4. Chemical industry

5. Laboratory and research

High purity Niobium wire Packing

Niobium wire wrapped in woven bag, and the external wooden packing cable ties are tightened to ensure safety during transportation.

Why choose us

1. Rich experience in metal industry and we can give you professional advice when you choose in your application

2. Stock products with various grade and size, we can arrange quick delivery.

3. We offer FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

Application Advantages

The High Purity Niobium Wire is widely used in a variety of industries:

- Aerospace & Defense: Components for high-temperature applications, rocket propulsion, and structural parts.

- Electronics & Semiconductors: Vacuum tubes, sputtering targets, and other high-purity electronic components.

- Medical Equipment: Biocompatible surgical instruments, implants, and specialized medical devices.

- Chemical Processing: Ideal for high-corrosion environments, including reactors, pipelines, and chemical transfer systems.

- Energy & Environmental Engineering: Applications in high-temperature reactors, heat exchangers, and corrosion-resistant installations.

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

The production process of High Purity Niobium Wire involves multiple controlled steps:

- Raw Material Inspection: High-purity niobium ingots undergo chemical and mechanical analysis.

- Vacuum Melting: Produces a contaminant-free niobium melt.

- Hot Extrusion & Forging: Forms the ingots into preliminary wire shapes.

- Cold Drawing & Annealing: Enhances mechanical properties, dimensional accuracy, and surface finish.

- Precision Sizing: Ensures exact diameter and tolerance requirements.

- Final Inspection & Cleaning: Verifies quality and readiness for shipment.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Every High Purity Niobium Wire is subject to rigorous quality control procedures:

- Chemical Composition Testing to confirm material purity.

- Dimensional Accuracy Checks for diameter consistency.

- Mechanical Testing including tensile strength, elongation, and hardness.

- Surface Finish Examination to ensure smooth, defect-free wire.

- Non-Destructive Testing for internal flaws.

- These quality assurance measures ensure our wire consistently meets international standards.

R&D and Customization

Our R&D team focuses on developing and optimizing High Purity Niobium Wire for specific industrial needs. Services include:

- Custom wire diameters, lengths, and tolerances

- Surface treatments and coating options

- Alloy adjustments for special applications

- Prototype and small-batch production for research or pilot projects

- Continuous innovation allows us to provide high-performance, tailored wire solutions.

Packaging & Global Logistics

Each High Purity Niobium Wire is carefully packaged to ensure safe transport:

- Wrapped in anti-rust film or vacuum packaging to prevent oxidation

- Foam padding or protective reels to avoid deformation

- Placed in export-standard wooden boxes with clear labels indicating specifications and batch numbers

We provide reliable global shipping solutions via air, sea, and land to ensure timely delivery to more than 50 countries worldwide.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Chuanghui Daye offers complete OEM and customization services for High Purity Niobium Wire, including:

- Custom lengths, diameters, and grades

- Wire drawing and surface finishing per client specifications

- Small-batch or large-scale production

- Technical consultation for material selection and application optimization

Our team ensures each wire meets exact requirements with consistent quality.

Inspection Process

The High Purity Niobium Wire undergoes a strict inspection workflow:

- Incoming Material Verification

- Process Control Monitoring

- Intermediate Diameter & Surface Checks

- Mechanical & Chemical Testing

- Final Packaging Verification

This process guarantees traceable, reliable, and high-quality wire for all customers.

Why Choose Us

- 30+ Years of Industry Experience in rare metals

- ISO 9001:2015 Certified Quality Management System

- Advanced Production Facilities including electron beam furnaces and drawing machines

- 7-Day Fast Delivery for standard specifications

- Global Export Experience to over 50 countries

- Professional OEM & Customization Services tailored to your specific needs

Chuanghui Daye is your trusted supplier for High Purity Niobium Wire, delivering superior performance, precise dimensions, and dependable supply.

|

|

|

|

|

|

FAQs

Q1: What standards do your High Purity Niobium Wires comply with?

A1: All wires meet ASTM, AMS, ISO, and GB standards.

Q2: Can you provide custom diameters and lengths for High Purity Niobium Wire?

A2: Yes, we offer full customization according to client specifications.

Q3: How do you ensure wire quality?

A3: Through chemical analysis, mechanical testing, surface inspection, and non-destructive testing.

Q4: What is the typical lead time for orders?

A4: Standard wires ship within 7 days; customized orders vary based on size and quantity.

Q5: Do you ship internationally?

A5: Yes, we provide air, sea, and land shipping solutions worldwide.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email