- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

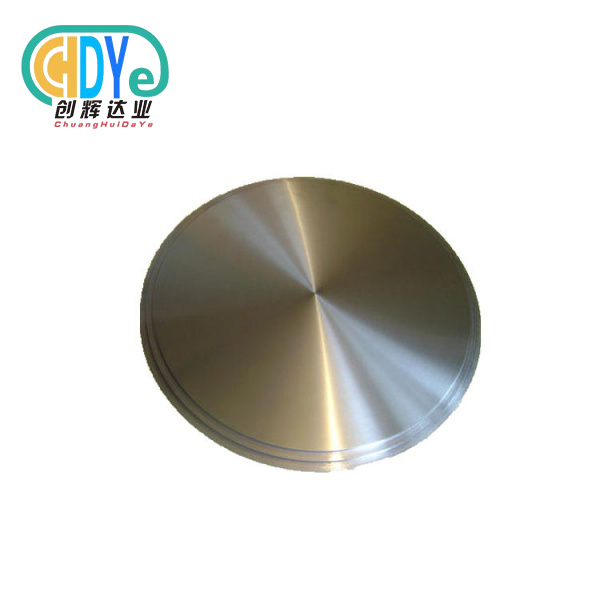

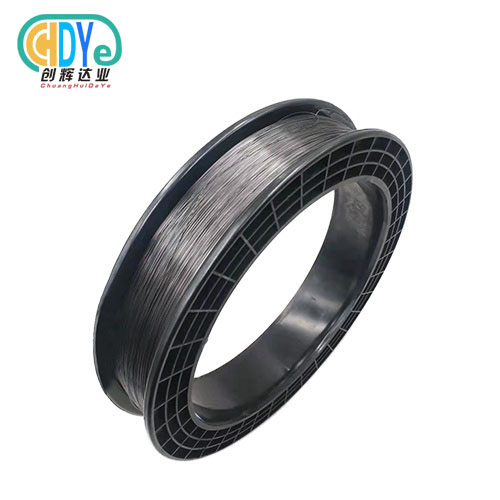

Molybdenum Wire For Edm

2.Surface: Black or alkali washing

3.Certificate: ISO9001:2015

4.Standard:ASTM B 387

Product Introduction

The Molybdenum Wire For Edm supplied by Shaanxi Chuanghui Daye Metal Material Co., Ltd. is a high-purity molybdenum product designed specifically for Electrical Discharge Machining (EDM) applications. Manufactured with advanced drawing and annealing processes, this wire offers outstanding mechanical strength, excellent electrical conductivity, and exceptional resistance to high-temperature oxidation.

With more than 30 years of expertise in rare metal production, our company ensures that every molybdenum wire meets strict international standards such as ASTM B387 and GB/T 4182. The product is available in various diameters and spool sizes, offering consistent performance in high-precision cutting of conductive materials like steel, copper, and tungsten carbide. It ensures stable discharge, high cutting accuracy, and extended operational life for all EDM machines.

Molybdenum wire has high strength, high melting point, corrosion resistance, and wear resistance. Specifically, molybdenum wire in online cutting processing exhibits characteristics such as high strength, good discharge performance, high surface smoothness, fast cutting speed, and long service life. In addition, molybdenum wire also has good conductivity and is commonly used as the filament and lead wire of light bulbs.

Size: Dia 0.18*2000M

Surface: Black or alkali washing

Certificate: ISO9001:2015

Standard:ASTM B 387

Features

• High melting point, Low density and Thermal coefficients

• Good thermal conductivity properties and Resistance of high-temperature

• High tensile strength and Low elongation

• Good stability and High precision of cutting

• High speed and Long stable time of processing

• Long lifetime and Non-poisonous

Application

• Electric light source, Electrode

• Heating elements, High-temperature components

• Wire-electrode cutting

• Spraying for auto parts

Be used in a wide range of industries.

Steel industry

Electronic devices

Furnace components

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

Our Molybdenum Wire For Edm is produced using advanced metallurgical techniques and controlled environments to guarantee purity, strength, and consistency:

- Raw Material Selection: High-purity molybdenum powder (≥99.95%) is sourced and inspected to ensure chemical stability.

- Powder Pressing: The powder is compacted under isostatic pressure to achieve uniform density.

- Vacuum Sintering: High-temperature sintering in a vacuum furnace enhances grain structure and mechanical strength.

- Hot and Cold Drawing: Multiple precision drawing steps refine wire diameter and improve surface finish.

- Annealing Treatment: Controlled thermal processing relieves stress and enhances ductility.

- Surface Cleaning: Electrochemical and chemical polishing ensure a bright, oxidation-free finish.

- Spooling and Packaging: The wire is wound on spools under controlled tension for smooth and consistent unwinding.

Each stage is monitored by experienced technicians to ensure dimensional precision, surface integrity, and mechanical performance.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Shaanxi Chuanghui Daye maintains a strict ISO 9001:2015-certified quality management system to ensure every wire meets or exceeds specifications. Quality assurance includes:

- Chemical Composition Analysis: Confirms molybdenum purity and impurity control below 0.05%.

- Dimensional Inspection: Wire diameter tolerance controlled within ±0.002 mm.

- Mechanical Testing: Verification of tensile strength, elongation, and straightness.

- Surface Examination: Microscopic and visual inspection for cracks, bends, or oxidation.

- Electrical Conductivity Test: Ensures optimal discharge stability during EDM cutting.

- Coating and Oxidation Resistance Check: Tests for durability under repeated thermal exposure.

Through rigorous inspection and documentation, we guarantee consistent quality across all batches.

R&D and Customization

With a dedicated R&D team and advanced facilities, Shaanxi Chuanghui Daye continually develops innovative molybdenum wire solutions to meet evolving industrial demands. We provide customization in:

- Wire Diameter: Ranging from 0.10 mm to 0.35 mm or per customer specifications.

- Spool Length and Packaging: Adjustable according to machine type or project requirement.

- Wire Type: Options for pure molybdenum or doped alloys for improved wear resistance.

- Surface Treatment: Clean, lubricated, or coated finishes to suit specific cutting applications.

- Performance Optimization: Tailored electrical and tensile properties for different EDM systems.

Our customization service ensures seamless compatibility with various domestic and imported EDM machines.

Packaging & Global Logistics

Every Molybdenum Wire For Edm is packed and delivered with utmost care to ensure quality preservation during transit:

- Packaging: Anti-static spools wrapped in vacuum-sealed or moisture-proof film.

- Protection: Foam-lined boxes and anti-corrosion layers prevent mechanical damage.

- Marking: Each spool labeled with product specifications, batch number, and production date.

- Shipping: Flexible delivery by air, sea, or express courier with full tracking service.

- Storage: Recommended to store in a dry, clean environment to prevent oxidation.

With over 50 global export markets, including Europe, North America, and Asia, we ensure on-time and safe delivery to all customers.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Our OEM and ODM capabilities enable customers to receive fully customized molybdenum wire products, whether for industrial supply, private labeling, or specialized cutting applications.

We offer:

- Custom diameter and tensile strength requirements

- Label and logo customization

- Prototype and small-batch manufacturing

- Technical support for EDM parameter optimization

- Comprehensive after-sales consultation

Our goal is to help clients improve EDM efficiency while reducing consumable costs.

Inspection Process

Every production batch undergoes a comprehensive inspection process before shipment:

- Raw Material Testing – Chemical purity and density verification.

- Wire Drawing Inspection – Check for uniform diameter and straightness.

- Surface Quality Review – Detect surface oxidation or contamination.

- Tensile Testing – Measure strength and elongation rate.

- Electrical Conductivity Test – Verify consistent discharge performance.

- Final Visual & Packaging Inspection – Ensure defect-free presentation and labeling accuracy.

Only after passing all tests does each spool proceed to final packaging and delivery.

Why Choose Us

- Over 30 years of manufacturing experience in refractory metals.

- Advanced electron beam and vacuum sintering furnaces for superior product quality.

- ISO 9001:2015 certified quality system ensuring full traceability.

- Strong export record across 50+ countries.

- Rapid delivery within 7 working days for standard specifications.

- Professional OEM/ODM and technical support.

- Commitment to reliability, precision, and long-term customer success.

We deliver not only materials—but trust, performance, and partnership.

|

|

|

|

|

|

FAQs

Q1: What advantages does molybdenum wire offer for EDM compared to brass or copper wire?

A1: Molybdenum wire offers superior tensile strength, higher melting point, and longer lifespan, reducing wire consumption and downtime.

Q2: What is the typical diameter range available?

A2: Standard diameters range from 0.10 mm to 0.35 mm, with custom options available upon request.

Q3: Can you supply molybdenum wire compatible with different EDM machines?

A3: Yes, our products are compatible with most global EDM brands, including Sodick, Mitsubishi, and Charmilles.

Q4: How is quality ensured before shipping?

A4: Each spool undergoes multiple inspections including dimensional, mechanical, and surface quality testing.

Q5: What are the delivery and payment terms?

A5: Standard orders are shipped within 7 days, with flexible payment options including T/T and L/C.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email