- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

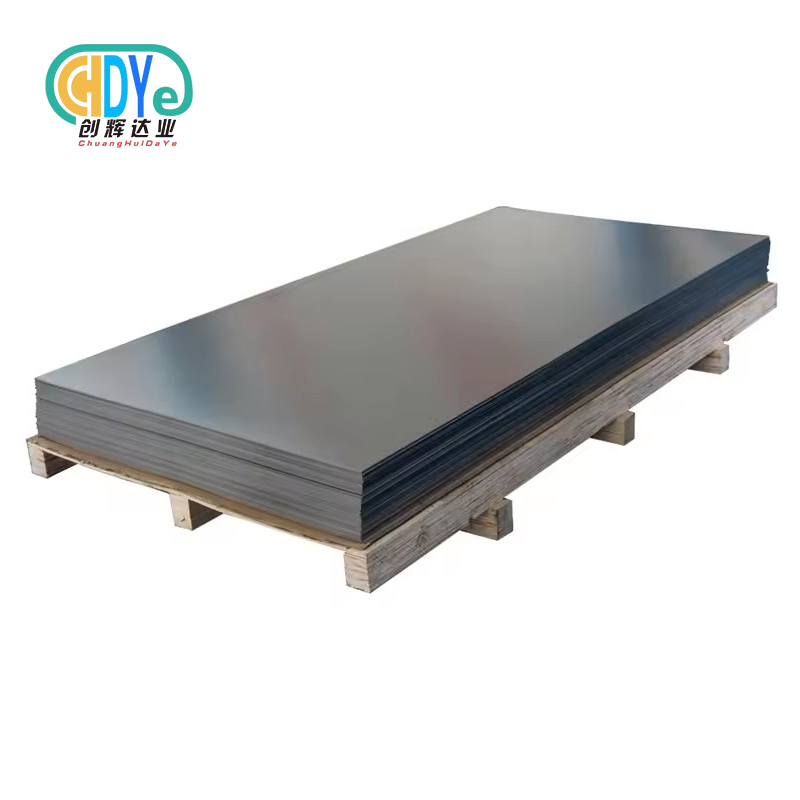

cold rolling niobium sheet

2. Thickness: 0.2–20 mm

3. Width: 1000 mm

4. Length: 3000 mm, customized

5. Density: 8.57 g/cm³

6. Process: Cold rolled

7. Applications: Electronics, chemical

Looking for high-performance cold rolling niobium sheets for your industrial applications? At Shaanxi Chuanghui Daye Metal Material Co., Ltd., we specialize in manufacturing premium-grade niobium plates using advanced cold rolling technology. Our plates offer exceptional purity levels exceeding 99.9%, making them ideal for demanding applications in electronics, chemical processing, and specialized industrial uses. With over 30 years of expertise in rare metal manufacturing, we deliver reliable solutions that meet your exact specifications and quality requirements.

Key Features and Benefits

Our niobium plates deliver outstanding performance across multiple applications. The cold rolling process ensures superior surface finish and dimensional accuracy. You'll benefit from excellent corrosion resistance and biocompatibility. The high melting point of 2,477°C makes these plates perfect for high-temperature environments. Low thermal neutron capture cross-section provides advantages in nuclear applications.

Technical Specifications

| Property | Specification |

|---|---|

| Alloy Composition | Nb >99.9% |

| Thickness Range | 0.2–20 mm |

| Width | Up to 1000 mm |

| Length | Up to 3000 mm |

| Density | 8.57 g/cm³ |

| Processing Method | Cold Rolled |

| Melting Point | 2,477°C |

| Surface Finish | Bright, smooth |

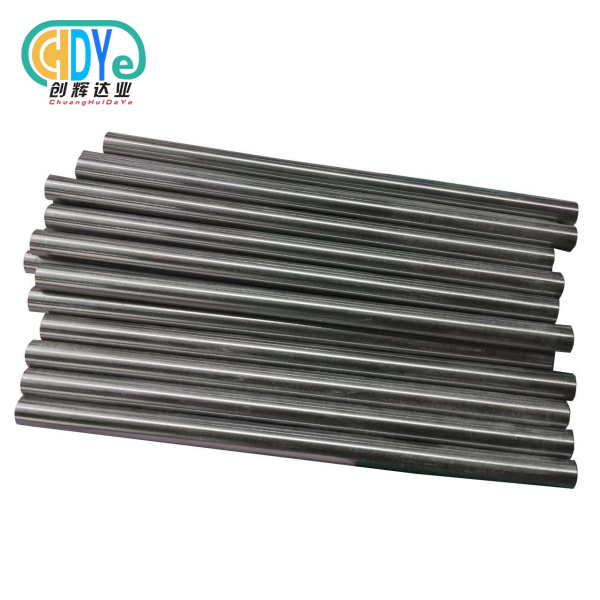

| Shape type | Plate/Sheet/Foil/Strip, round, block, cube, ingot etc. |

| Payment terms | 30%TT in advance,70% balance payment before delivery according to the actual weight |

|

Chemical Composition |

||||

|

Element |

Type1 (Reactor Grade Unalloyed Nb) R04200 |

Type2 (Commercial Grade Unalloyed Nb) R04210 |

Type3 (Reactor Grade Nb-1%Zr) R04251 |

Type4 (Commercial Grade Nb-1%Zr) R04261 |

|

Max Weight % (Except Where Otherwise Specified) |

||||

|

C |

0.01 |

0.01 |

0.01 |

0.01 |

|

N |

0.01 |

0.01 |

0.01 |

0.01 |

|

O |

0.015 |

0.025 |

0.015 |

0.025 |

|

H |

0.0015 |

0.0015 |

0.0015 |

0.0015 |

|

Zr |

0.02 |

0.02 |

0.8-1.2 |

0.8-1.2 |

|

Ta |

0.1 |

0.3 |

0.1 |

0.5 |

|

Fe |

0.005 |

0.01 |

0.005 |

0.01 |

|

Si |

0.005 |

0.005 |

0.005 |

0.005 |

|

W |

0.03 |

0.05 |

0.03 |

0.05 |

|

Ni |

0.005 |

0.005 |

0.005 |

0.005 |

|

Mo |

0.01 |

0.02 |

0.01 |

0.05 |

|

Hf |

0.02 |

0.02 |

0.02 |

0.02 |

|

Ti |

0.02 |

0.03 |

0.02 |

0.03 |

Mechanical Requirement (Annealed condition):

|

Grade |

Tensile strength δbpsi (MPa), ≥ |

Yield strength δ0.2, psi (MPa),≥ |

Elongation in 1"/2" gage length, %, ≥ |

|

RO4200-1 |

18000 (125) |

12000 (85) |

25 |

|

RO4210-2 |

Plate Size(0.1~6.0)*(120~420)*(50~3000)mm:

|

Thickness |

The allowable deviation thickness |

Width |

The allowable deviation Width |

Length |

|

|

Width>120~300 |

Width>300 |

||||

|

0.1~0.2 |

±0.015 |

±0.02 |

>300~420 |

±2.0 |

>100 |

|

>0.2~0.3 |

±0.02 |

±0.03 |

>200~420 |

±2.0 |

>100 |

|

>0.3~0.5 |

±0.03 |

±0.04 |

>200~420 |

±2.0 |

50~3000 |

|

>0.5~0.8 |

±0.04 |

±0.06 |

>200~420 |

±2.0(±5.0) |

50~3000 |

|

>0.8~1.0 |

±0.06 |

±0.08 |

>200~420 |

±2.0(±5.0) |

50~3000 |

|

>1.0~1.5 |

±0.08 |

±0.10 |

>200~420 |

±3.0(±5.0) |

50~3000 |

|

>1.5~2.0 |

±0.12 |

±0.14 |

>200~420 |

±3.0(±5.0) |

50~3000 |

|

>2.0~3.0 |

±0.16 |

±0.18 |

>200~420 |

±5.0 |

50~3000 |

|

>3.0~4.0 |

±0.18 |

±0.20 |

>200~420 |

±5.0 |

50~3000 |

|

>4.0~6.0 |

±0.20 |

±0.24 |

>200~420 |

±5.0 |

50~3000 |

Available Grades and Materials

We offer various grades of niobium materials to suit your specific needs. Pure niobium grades provide maximum corrosion resistance. Commercial purity grades balance performance with cost-effectiveness. Custom alloy compositions are available upon request. All materials meet international quality standards and specifications.

Manufacturing Process

Our cold rolling process begins with premium-grade niobium ingots. Multiple rolling passes achieve desired thickness and surface quality. Intermediate annealing ensures optimal mechanical properties. Quality control inspections occur at every stage. Final products undergo comprehensive testing before shipment.

|

|

|

|

|

|

|

|

Applications and Industries

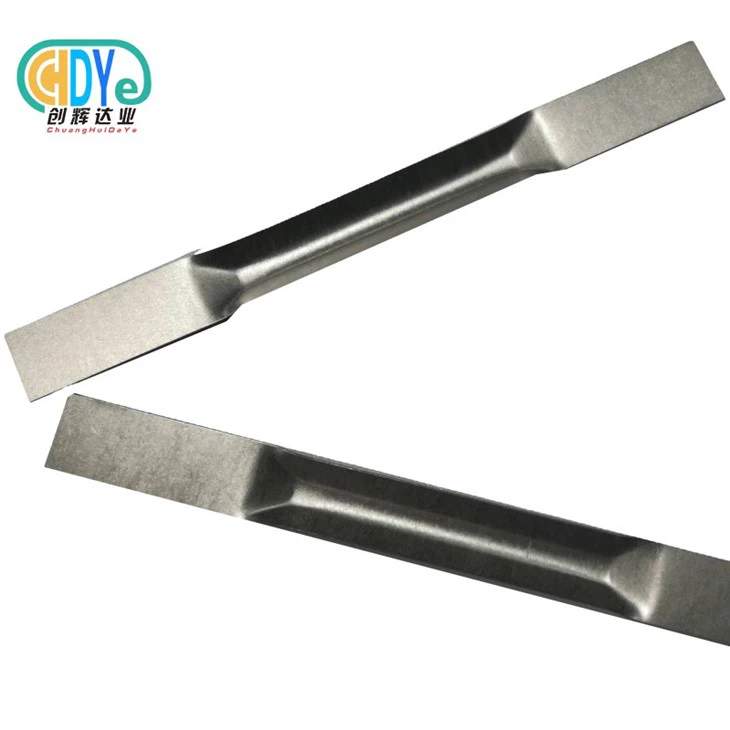

Cold rolling niobium sheets serve diverse industrial sectors effectively. Electronics industry uses them for capacitor manufacturing and semiconductor applications. Chemical processing plants rely on their corrosion resistance for reactor components. Medical device manufacturers value their biocompatibility for implant applications. Aerospace industry utilizes them for high-temperature components.

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

We maintain strict dimensional tolerances across all products. Thickness tolerance: ±0.05mm for thin plates. Width tolerance: ±2mm for standard dimensions. Length tolerance: ±5mm for cut-to-length pieces. Custom dimensions available to meet your specific requirements.

Product Features in Detail

Our plates exhibit exceptional ductility for easy forming operations. Superior weldability enables complex fabrication processes. Excellent thermal conductivity ensures efficient heat transfer. Low work hardening rate facilitates multiple forming operations. Consistent grain structure provides uniform mechanical properties throughout.

Quality Assurance and Testing

Every batch undergoes rigorous quality testing procedures. Chemical composition analysis confirms purity levels. Mechanical property testing validates strength characteristics. Surface quality inspection ensures defect-free products. Dimensional verification confirms specification compliance. All testing follows international standards and protocols.

|

|

|

OEM & Customization Services

We provide comprehensive customization services for unique applications. Custom alloy compositions developed for specific requirements. Specialized surface treatments available upon request. Precision cutting and forming services offered. Technical support throughout the development process ensures optimal results.

Packaging and Shipping

Products receive protective packaging to prevent damage during transport. Moisture-resistant wrapping protects against contamination. Wooden crates provide secure shipping for larger orders. International shipping available to over 50 countries worldwide. Tracking information provided for all shipments.

|

|

|

|

|

|

|

|

|

Why Choose Us

Located in China's "Titanium Capital," we leverage decades of rare metal expertise. Our founder's 30+ years experience ensures superior product quality. State-of-the-art facilities enable consistent manufacturing excellence. Competitive pricing without compromising quality standards. Reliable delivery schedules meet your project timelines effectively.

|

|

|

|

|

|

Contact Us

Ready to discuss your niobium sheet requirements? Our technical team stands ready to assist with product selection and specification development. Contact us today for detailed quotations, technical specifications, or application guidance. We're committed to providing exceptional service and premium-quality cold rolling niobium sheets that exceed your expectations.

E-mail: info@chdymetal.com

Mobole/what's app.: 86-18049386902

Learn about our latest products and discounts through SMS or email