- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

polishing tantalum rod

2. Diameter: 1–50 mm

3. Length: As your reqest

4. Density: 16.65 g/cm³

5. Tensile strength: 200–300 MPa

6. Applications: Chemical, lab

7. Surface: Polished

Product Introduction

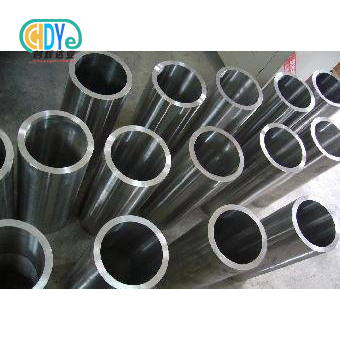

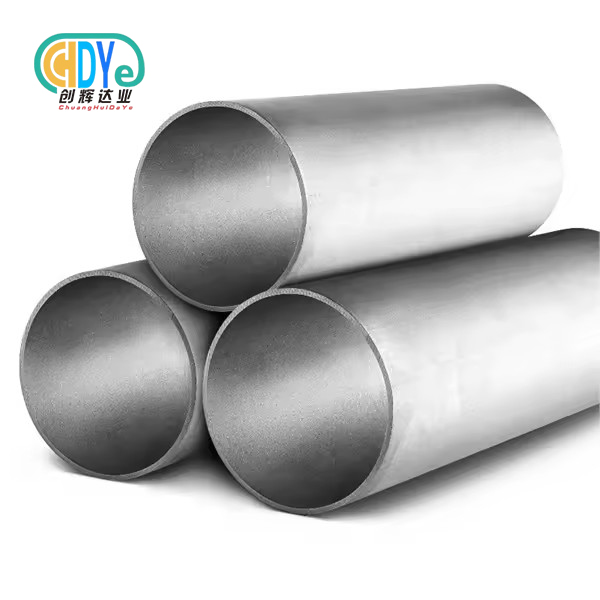

Looking for superior quality polishing tantalum rod for your industrial needs? Shaanxi Chuanghui Daye Metal Material Co., Ltd. offers premium tantalum rods with exceptional surface finish and outstanding performance characteristics. Our tantalum rods feature high purity levels exceeding 99.9%, making them ideal for demanding applications in chemical processing, laboratory equipment, and high-temperature environments. Each rod undergoes precise manufacturing processes to ensure consistent quality and reliability you can trust.

Key Features and Benefits

Our tantalum rods deliver exceptional value through superior corrosion resistance and thermal stability. You'll benefit from their outstanding chemical inertness, making them perfect for harsh environments. The polished surface finish provides excellent aesthetics and functional performance. These rods maintain structural integrity even under extreme conditions, ensuring long-lasting performance for your applications.

Technical Specifications

| Property | Specification |

|---|---|

| Alloy Composition | Ta >99.9% |

| Diameter Range | 1–50 mm |

| Maximum Length | 1000 mm |

| Density | 16.65 g/cm³ |

| Tensile Strength | 200–300 MPa |

| Surface Finish | Polished |

| Melting Point | 3017°C |

| Certificate | ISO 90001:2015 |

| Delivery time | Normal size 7-15 days |

| Payments terms | 30%TT in advance,70%TT balance before delivery |

| Features |

1. Good ductility, good machinability 2.Good plasticity3. Excellent corrosion resistance 4. High melting point, high boiling point 5. Very small coefficients of thermal expansion 6. Good capability of absorbing and releasing hydrogen 7. Good biocompatibility |

Chemcial composition

|

Grade |

Chemical Composition (≤%) |

||||||||||||

|

Ta |

Fe |

Si |

Ni |

W |

Mo |

Ti |

Nb |

O |

C |

H |

N |

||

|

Ta1 |

Bal. |

0.005 |

0.005 |

0.002 |

0.01 |

0.01 |

0.002 |

0.03 |

0.015 |

0.01 |

0.0015 |

0.01 |

|

|

Ta2 |

Bal. |

0.03 |

0.02 |

0.005 |

0.04 |

0.03 |

0.005 |

0.1 |

0.02 |

0.01 |

0.0015 |

0.01 |

|

|

Ta2.5W |

Bal. |

0.005 |

0.005 |

0.002 |

3.0 |

0.01 |

0.002 |

0.04 |

0.015 |

0.01 |

0.0015 |

0.01 |

|

|

Ta10W |

Bal. |

0.005 |

0.005 |

0.002 |

11 |

0.01 |

0.002 |

0.04 |

0.015 |

0.01 |

0.0015 |

0.01 |

|

Physical properties

|

Grade(UNS) |

Annealed |

||

|

Tensile strength min,psi (MPa) |

Yield strength min,psi (MPa)(2%) |

Elongation min,% (1 inch gage length) |

|

|

Pure Ta (RO5200,RO5400) |

30000 (207) |

20000 (138) |

20 |

|

Ta-10W (RO5255) |

70000 (482) |

60000 (414) |

15 |

|

Ta-2.5W (RO5252) |

40000 (276) |

30000 (207) |

20 |

Available Grades and Materials

We offer high-purity tantalum grades suitable for various industrial requirements. Our standard grade features tantalum content exceeding 99.9%, ensuring optimal performance in critical applications. Custom alloy compositions are available upon request to meet your specific project requirements.

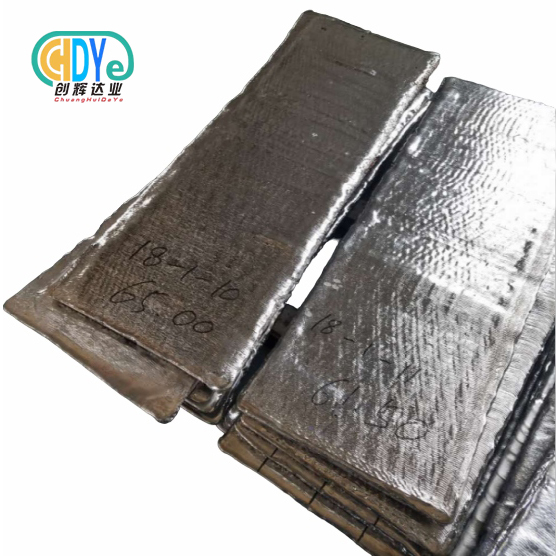

Manufacturing Process

Our polishing tantalum rod production follows strict quality protocols. The process begins with high-grade tantalum ingots, followed by cold working techniques including forging, rolling, and drawing. Each rod undergoes precision machining and polishing to achieve the desired surface finish. Final inspection ensures dimensional accuracy and surface quality meet your specifications.

|

|

|

|

|

|

|

|

Applications and Industries

Tantalum rods serve critical roles across multiple industries. Chemical processing plants rely on their corrosion resistance for reactor components. Laboratory equipment manufacturers value their inert properties for analytical instruments. Aerospace applications utilize their high-temperature stability in turbine components. Electronic industries depend on their excellent dielectric properties for capacitor manufacturing.

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

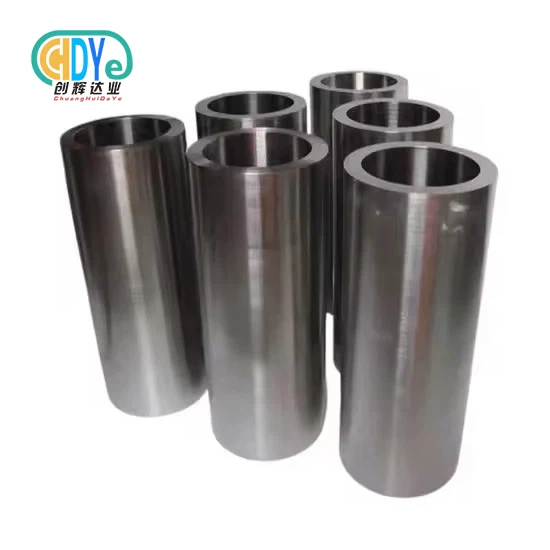

Product Dimensions and Tolerances

Standard diameter tolerances are maintained at ±0.1mm for optimal fit and function. Length specifications can be customized from 10mm to 1000mm based on your requirements. Surface roughness values typically range from Ra 0.8 to Ra 1.6 micrometers, providing excellent finish quality for demanding applications.

Product Features in Detail

The polished surface of our tantalum rods offers both functional and aesthetic advantages. You'll appreciate the smooth finish that reduces friction and wear in moving applications. The high-purity composition ensures minimal impurities that could affect performance. Excellent machinability allows for secondary operations when needed. Superior thermal conductivity enables efficient heat transfer in high-temperature applications.

Quality Assurance and Testing

Every batch undergoes comprehensive testing to verify chemical composition and mechanical properties. Dimensional inspections ensure conformance to specifications. Surface quality checks guarantee consistent finish standards. Material certificates accompany each shipment, providing complete traceability for your quality records.

|

|

|

OEM & Customization Services

We understand that your projects may require specific dimensions or properties. Our engineering team works closely with you to develop custom solutions. Whether you need special lengths, diameters, or surface treatments, we can accommodate your requirements. Prototype quantities are available for testing and validation before full production runs.

Packaging and Shipping

Your polishing tantalum rod orders receive careful packaging to prevent damage during transit. Individual rods are wrapped in protective materials and secured in rigid containers. International shipping options ensure timely delivery to your location. Proper documentation accompanies each shipment for smooth customs clearance.

|

|

|

|

|

|

|

|

|

Why Choose Us

With over 30 years of experience in rare metal processing, we bring unmatched expertise to every project. Our location in China's "Titanium Capital" provides access to premium raw materials and advanced manufacturing capabilities. We've successfully served customers in more than 50 countries, building a reputation for quality and reliability. Our commitment to customer satisfaction drives continuous improvement in our products and services.

|

|

|

|

|

|

FAQs

Q: What is the minimum order quantity?

A: We accommodate orders from small prototype quantities to large production runs.

Q: Can you provide material certificates?

A: Yes, complete material certificates accompany every shipment.

Q: What surface finishes are available?

A: Standard polished finish is available, with custom surface treatments upon request.

Q: How do you ensure dimensional accuracy?

A: Our precision manufacturing equipment and quality control processes maintain tight tolerances.

Contact Us

Ready to discuss your polishing tantalum rod requirements? Our technical team is standing by to assist with product selection and custom solutions. Contact us today for quotes, technical specifications, or application guidance. We look forward to becoming your trusted partner for premium tantalum products.

E-mail: info@chdymetal.com

Mob./what's app: 86-18049386902

Learn about our latest products and discounts through SMS or email