- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

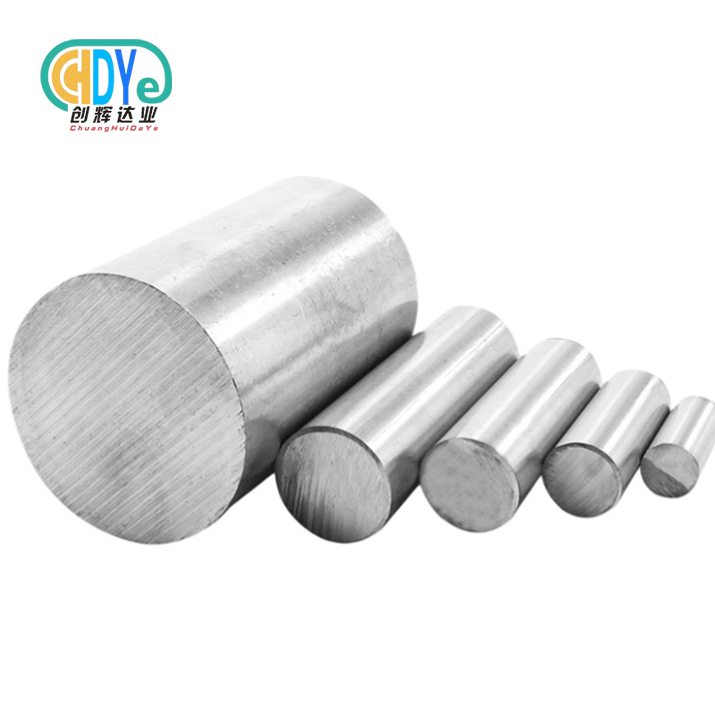

99.99% high purity niobium granule

2.Grade: R04200, R04210, R04251, R04261, R04295

3.Purity: 99.95% and 99.99%

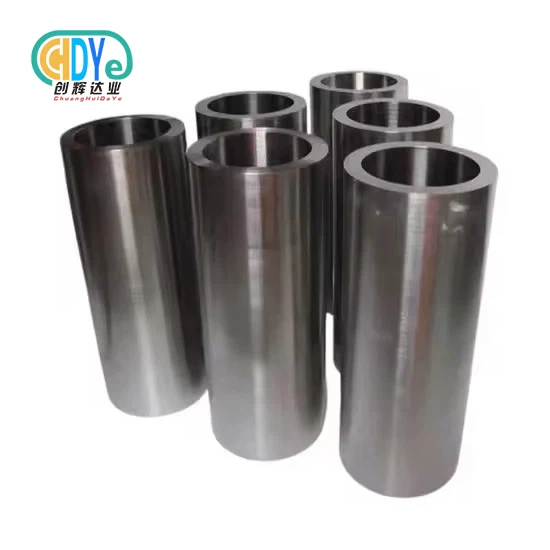

Product Introduction

Our high purity niobium granule represent the pinnacle of refractory metal engineering. These versatile products combine exceptional corrosion resistance with superior mechanical properties. You'll find them perfect for high-temperature applications where other metals fail.

Each product undergoes rigorous quality control. We ensure every piece meets your exact specifications. Our manufacturing process guarantees consistent quality across all dimensions and grades.

Key Features and Benefits

- Superior Corrosion Resistance: Withstands most acids and alkaline solutions at room temperature

- Excellent Ductility: Easy to form and machine for complex applications

- High-Temperature Stability: Maintains properties at elevated temperatures

- Biocompatibility: Safe for medical and body jewelry applications

- Superconducting Properties: Becomes superconducting at 9.15°K

- Chemical Inertness: Unaffected by most chemicals at ordinary temperatures

Technical Specifications

Packing

Foam material inside, wooden box outside

|

Chemcal composition% |

||||||||||||

|

Grade |

MAIN COMPONENT |

Other impurities: Maximum | ||||||||||

|

Nb |

Fe |

Si |

Ni |

W |

Mo |

Ti |

Ta |

O |

C |

H |

N |

|

|

Nb1 |

Balance |

0.004 |

0.004 |

0.002 |

0.005 |

0.005 |

0.002 |

0.05 |

0.012 |

0.0035 |

0.0012 |

0.003 |

|

Nb2 |

Balance |

0.01 |

0.01 |

0.005 |

0.02 |

0.01 |

0.004 |

0.07 |

0.015 |

0.0050 |

0.0015 |

0.005 |

|

If there are any special requirements, they shall be agreed upon by both parties. |

||||||||||||

Available Grades and Materials

We offer various grades to meet your specific requirements:

- R04200: Commercial pure niobium (99.9% min)

- R04210: High-purity niobium (99.95% min)

Each grade comes with complete material certifications. You can trust our documentation for your quality assurance needs.

Manufacturing Process

Our advanced manufacturing process ensures optimal product quality:

- Raw Material Selection: We source only the highest purity niobium

- Vacuum Melting: Maintains purity and eliminates contamination

- Hot Rolling: Achieves desired thickness with excellent surface finish

- Annealing: Optimizes mechanical properties and stress relief

- Cold Rolling: Provides precise dimensional control

- Final Processing: Cutting, polishing, and quality inspection

|

|

|

|

|

|

|

|

Applications and Industries

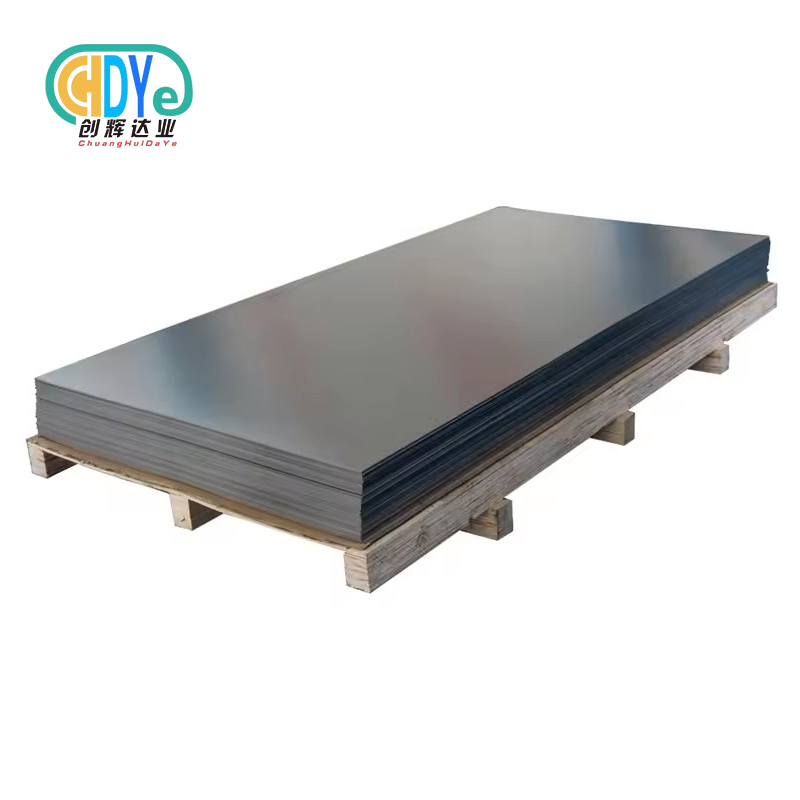

Our pure niobium plate/sheet serves numerous critical applications:

- Aerospace: Rocket nozzles and heat shields

- Chemical Processing: Reactor vessels and heat exchangers

- Electronics: Capacitors and superconducting devices

- Medical: Implants and surgical instruments

- Nuclear Industry: Reactor components

- Jewelry: High-end body jewelry and decorative items

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

We maintain strict tolerances for all dimensions:

- Thickness Tolerance: ±0.1 mm for sheets under 10 mm

- Width Tolerance: ±2 mm for standard widths

- Length Tolerance: ±5 mm for standard lengths

- Flatness: Less than 2 mm per meter

- Surface Roughness: Ra 0.8 μm or better

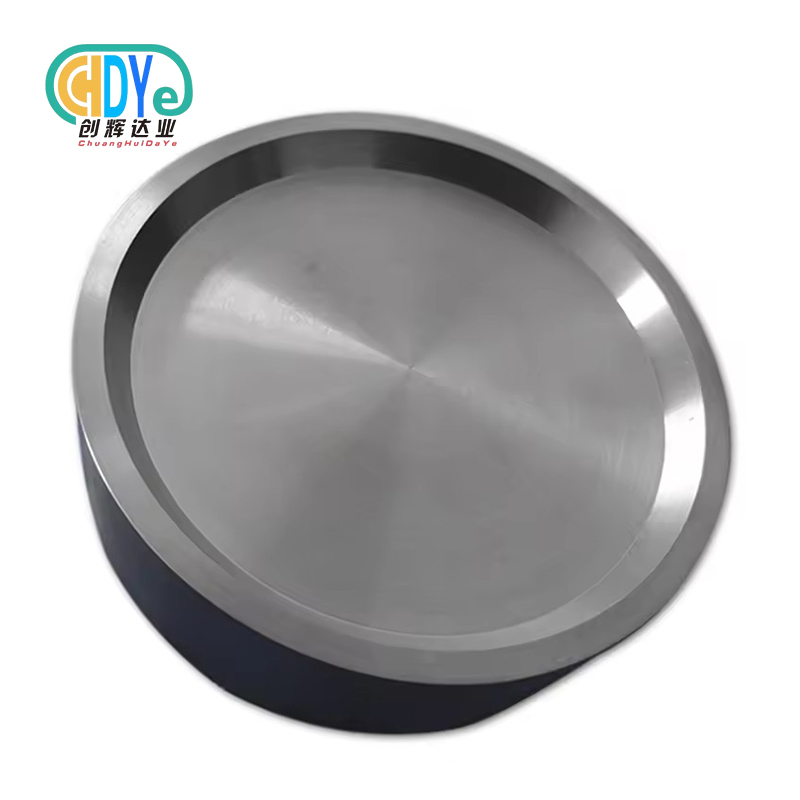

Product Features in Detail

Our niobium products excel in challenging environments. The material's unique properties make it ideal for applications requiring both strength and corrosion resistance.

The polished surface finish provides excellent appearance and cleanability. This makes our products perfect for medical and food processing applications.

Temperature cycling doesn't affect our niobium's performance. You can rely on consistent properties across wide temperature ranges.

Quality Assurance and Testing

Every batch undergoes comprehensive testing:

- Chemical Analysis: Verifies purity and composition

- Mechanical Testing: Confirms strength and ductility

- Dimensional Inspection: Ensures precise tolerances

- Surface Quality: Checks for defects and finish quality

- Documentation: Complete traceability records

|

|

|

OEM & Customization Services

We specialize in custom solutions for your unique requirements. Our engineering team works with you to develop optimized products. Whether you need special dimensions, surface treatments, or packaging, we deliver.

Custom machining services are available. We can provide finished components ready for your assembly processes.

Packaging and Shipping

Protective packaging ensures your products arrive in perfect condition:

- Individual Wrapping: Prevents surface damage during transport

- Wooden Crates: Secure packaging for international shipping

- Foam Padding: Additional protection for delicate surfaces

- Moisture Control: Prevents oxidation during storage

We ship worldwide with reliable logistics partners. Tracking information keeps you informed throughout delivery.

Why Choose Us

With over 30 years of rare metal expertise, we understand your needs. Our location in China's "Titanium Capital" provides access to the best raw materials and manufacturing facilities.

We've successfully served customers in over 50 countries. Our commitment to quality and customer service sets us apart from competitors.

Competitive pricing doesn't mean compromising quality. We deliver exceptional value through efficient manufacturing and direct sales.

|

|

|

|

|

|

FAQs

Q: What's the minimum order quantity?

A: We accommodate orders from small prototype quantities to large production runs.

Q: Can you provide material certificates?

A: Yes, complete material certificates accompany every shipment.

Q: What payment terms do you offer?

A: We accept various payment methods including T/T, L/C, and others based on order value.

Q: How long is the delivery time?

A: Standard products ship within 7-12days. Custom orders may require additional time.

Contact Us

Ready to discuss your high purity niobium granule requirements? Our technical team is here to help you select the perfect solution for your application.

Email us at info@chdymetal.com for immediate assistance. We'll provide detailed quotations and technical support for your project needs.

Let's work together to bring your vision to reality with premium niobium products that exceed your expectations.

Learn about our latest products and discounts through SMS or email