- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

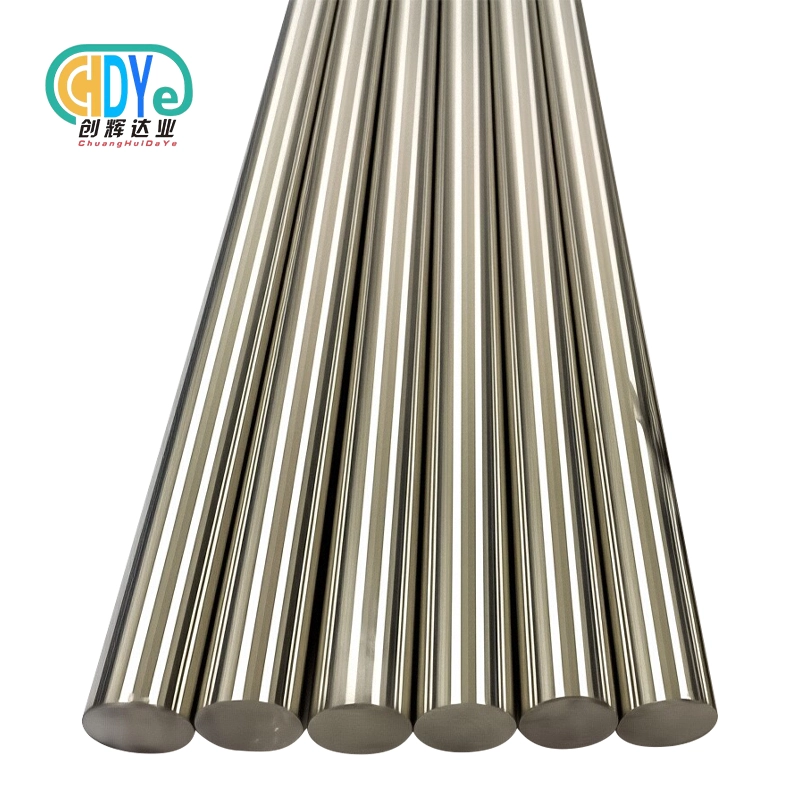

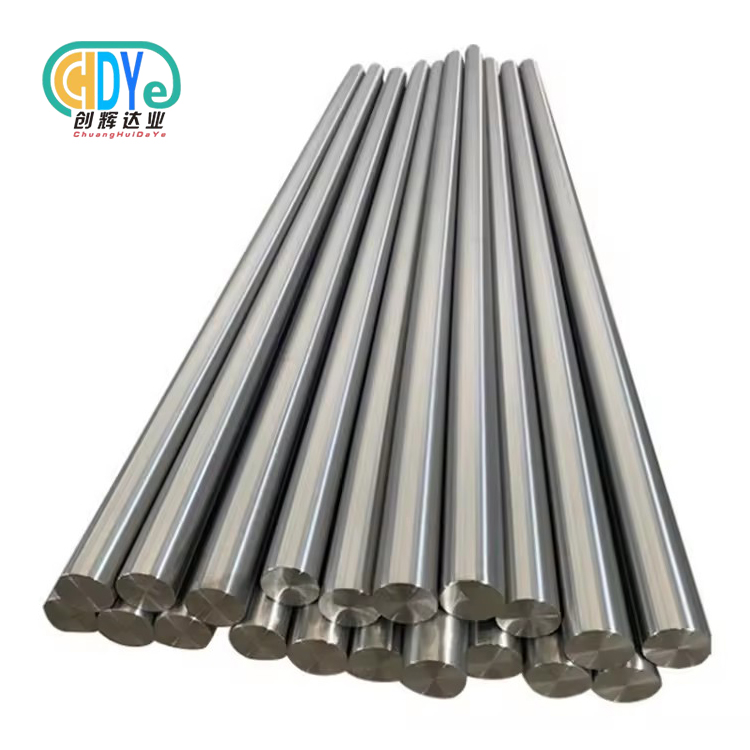

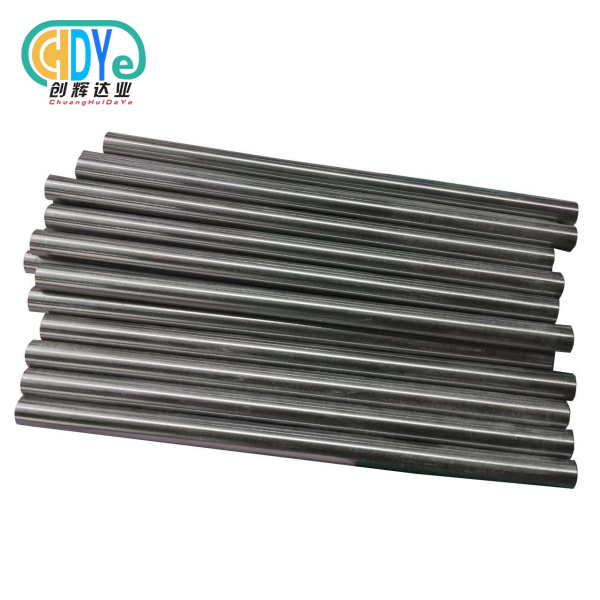

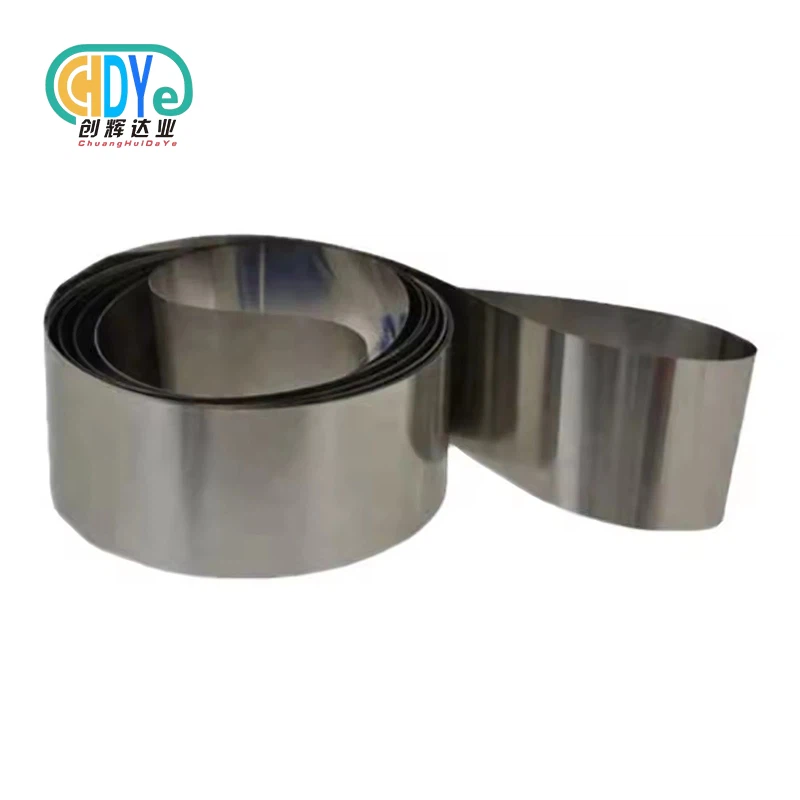

niobium plate / sheet

2. Material pure niobium and niobium alloy

3. Grade: RO4200.RO4210,R04251,R04261

Product introduction

Looking for exceptional niobium plate / sheet solutions for your critical applications? Shaanxi Chuanghui Daye Metal Material Co., Ltd. offers premium-grade niobium products engineered to meet the demanding requirements of aerospace, medical, and high-tech industries. Our niobium plate / sheet delivers outstanding performance with superior corrosion resistance, excellent thermal conductivity, and remarkable superconducting properties. With over 30 years of expertise in rare metal processing, we provide reliable solutions that exceed industry standards.

Key Features and Benefits

Superior Material Properties

- Exceptional corrosion resistance in harsh environments

- Outstanding thermal and electrical conductivity

- Excellent ductility and formability at room temperature

- Superior superconducting characteristics at low temperatures

Quality Advantages

- High purity levels (>99.95% Nb content)

- Consistent mechanical properties throughout

- Precise dimensional accuracy and surface finish

- Reliable performance in extreme conditions

Technical Specifications

|

Purity |

Nb ≥99.95% |

|

Grade |

R04200, R04210, R04251, R04261 |

|

Standard |

ASTM B393 |

|

Size |

Customized |

|

Melting point |

2468℃ |

|

Boiling point |

4742℃ |

|

Certificate |

ISO 9001:2015 |

|

Packing |

Foam material inside, wooden box outside. |

|

Payment terms |

30%TT in advance, 70% balance before shipment |

|

Delivery time |

Stock size will be arrange quick delivery within 1-3 days |

Chemcial Composition

|

Niobium and Niobium Alloys Sheet Chemical Composition |

||||

|

Element |

Type1 (Reactor Grade Unalloyed Nb) R04200 |

Type2 (Commercial Grade Unalloyed Nb) R04210 |

Type3 (Reactor Grade Nb-1%Zr) R04251 |

Type4 (Commercial Grade Nb-1%Zr) R04261 |

|

Max Weight % (Except Where Otherwise Specified) |

||||

|

C |

0.01 |

0.01 |

0.01 |

0.01 |

|

N |

0.01 |

0.01 |

0.01 |

0.01 |

|

O |

0.015 |

0.025 |

0.015 |

0.025 |

|

H |

0.0015 |

0.0015 |

0.0015 |

0.0015 |

|

Zr |

0.02 |

0.02 |

0.8-1.2 |

0.8-1.2 |

|

Ta |

0.1 |

0.3 |

0.1 |

0.5 |

|

Fe |

0.005 |

0.01 |

0.005 |

0.01 |

|

Si |

0.005 |

0.005 |

0.005 |

0.005 |

|

W |

0.03 |

0.05 |

0.03 |

0.05 |

|

Ni |

0.005 |

0.005 |

0.005 |

0.005 |

|

Mo |

0.01 |

0.02 |

0.01 |

0.05 |

|

Hf |

0.02 |

0.02 |

0.02 |

0.02 |

|

Ti |

0.02 |

0.03 |

0.02 |

0.03 |

Mechanical Requirement (Annealed condition):

|

Grade |

Tensile strength δbpsi (MPa), ≥ |

Yield strength δ0.2, psi (MPa),≥ |

Elongation in 1"/2" gage length, %, ≥ |

|

RO4200 |

18000 (125) |

12000 (85) |

25 |

|

RO4210 |

Plate Size(0.1~6.0)*(120~420)*(50~3000)mm:

|

Thickness |

The allowable deviation thickness |

Width |

The allowable deviation Width |

Length |

|

|

Width>120~300 |

Width>300 |

||||

|

0.1~0.2 |

±0.015 |

±0.02 |

>300~420 |

±2.0 |

>100 |

|

>0.2~0.3 |

±0.02 |

±0.03 |

>200~420 |

±2.0 |

>100 |

|

>0.3~0.5 |

±0.03 |

±0.04 |

>200~420 |

±2.0 |

50~3000 |

|

>0.5~0.8 |

±0.04 |

±0.06 |

>200~420 |

±2.0(±5.0) |

50~3000 |

|

>0.8~1.0 |

±0.06 |

±0.08 |

>200~420 |

±2.0(±5.0) |

50~3000 |

|

>1.0~1.5 |

±0.08 |

±0.10 |

>200~420 |

±3.0(±5.0) |

50~3000 |

|

>1.5~2.0 |

±0.12 |

±0.14 |

>200~420 |

±3.0(±5.0) |

50~3000 |

|

>2.0~3.0 |

±0.16 |

±0.18 |

>200~420 |

±5.0 |

50~3000 |

|

>3.0~4.0 |

±0.18 |

±0.20 |

>200~420 |

±5.0 |

50~3000 |

|

>4.0~6.0 |

±0.20 |

±0.24 |

>200~420 |

±5.0 |

50~3000 |

Available Grades and Materials

Pure Niobium Grades

- Commercial pure niobium (99.9% min)

- High-purity niobium (99.95% min)

- Ultra-high purity grades available upon request

Surface Conditions

- As-rolled surface for general applications

- Polished finish for high-precision requirements

- Custom surface treatments available

Manufacturing Process

Our advanced manufacturing process ensures consistent quality and performance:

Material Preparation: Starting with high-purity niobium ingots, we carefully control composition and minimize impurities.

Rolling Process: State-of-the-art rolling equipment produces uniform thickness and excellent surface quality.

Heat Treatment: Precise thermal processing optimizes mechanical properties and stress relief.

Quality Control: Comprehensive testing at every stage ensures dimensional accuracy and material integrity.

|

|

|

|

|

|

|

|

Applications and Industries

Aerospace Industry

Perfect for rocket engines, spacecraft components, and high-temperature structural parts where reliability is crucial.

Medical Technology

Essential for MRI equipment, surgical implants, and biocompatible medical devices requiring exceptional purity.

Superconducting Applications

Ideal for superconducting magnets, particle accelerators, and quantum computing components.

Chemical Processing

Excellent choice for corrosion-resistant equipment in aggressive chemical environments.

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

Standard Dimensions

- Thickness: ±0.05mm tolerance for sheets under 5mm

- Width: ±2mm tolerance for standard widths

- Length: ±5mm tolerance for cut lengths

Custom Sizing

We accommodate special dimensional requirements to meet your specific application needs.

Product Features in Detail

Corrosion Resistance: Our niobium plate / sheet demonstrates exceptional resistance to most acids and alkalis at room temperature, making it perfect for challenging chemical environments.

Thermal Properties: With excellent thermal conductivity and high melting point, these products perform reliably in extreme temperature applications.

Workability: The material exhibits excellent formability and can be easily machined, welded, and fabricated using standard metalworking techniques.

Quality Assurance and Testing

Comprehensive Testing Program

- Chemical composition analysis

- Dimensional inspection

- Surface quality verification

- Mechanical property testing

Certification Standards

All products meet international quality standards and come with detailed material certificates.

OEM & Customization Services

Custom Manufacturing

- Non-standard dimensions and specifications

- Special alloy compositions

- Unique surface treatments

- Application-specific solutions

Engineering Support

Our technical team provides expert guidance for material selection and application optimization.

Packaging and Shipping

Protective Packaging

Products are carefully packaged to prevent damage during transportation, with moisture protection and secure cushioning.

Global Delivery

We ship worldwide with reliable logistics partners, ensuring timely delivery to over 50 countries including the United States, Germany, South Korea, and Singapore.

Why Choose Us

Extensive Experience: Over 30 years of expertise in rare metal processing and manufacturing.

Quality Focus: Rigorous quality control ensures consistent, reliable products that meet your specifications.

Customer Service: Dedicated support team provides responsive service and technical assistance.

Competitive Pricing: Direct manufacturer pricing with excellent value for premium niobium plate / sheet products.

Reliable Partnership: We're committed to building long-term relationships based on trust, quality, and performance.

|

|

|

|

|

|

FAQs

Q: What is the minimum order quantity?

A: We accommodate both small prototype quantities and large production runs based on your requirements.

Q: Do you provide material certificates?

A: Yes, all products include comprehensive material certificates with composition and property data.

Q: Can you supply custom dimensions?

A: Absolutely! We specialize in custom sizing to meet your specific application needs.

Q: What is the typical lead time?

A: Lead times vary based on specifications and quantity, typically ranging from 1-2weeks.

Contact Us

Ready to discuss your niobium requirements? Our experienced team is here to help you find the perfect solution for your application.

Email: info@chdymetal.com

Contact us today for detailed quotations, technical specifications, or to discuss your custom requirements. We look forward to becoming your trusted partner for high-quality niobium products.

Learn about our latest products and discounts through SMS or email