- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

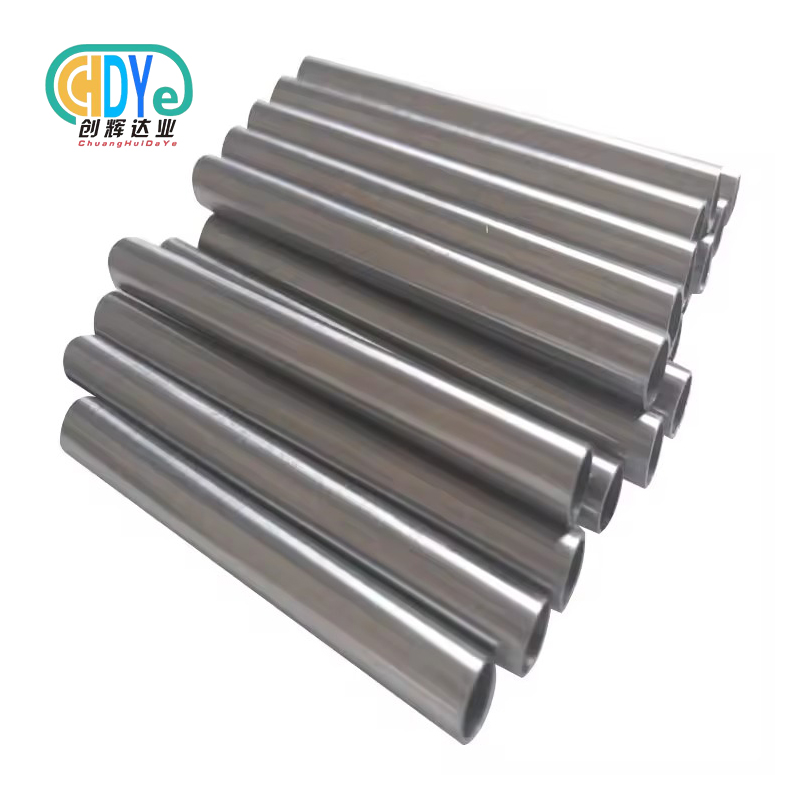

ASTM B 348 Industrial Titanium Rod

2. Grade: Gr1 Gr2,Gr5,Gr7,Gr5 Ell,Gr9, Gr12

3. Size: Dia(4mm-350mm)*Length(≤3000mm)

4. Standard: ASTMB348,ASTMF67,ASTMF136

5. Type: Round, Square, Hexagon

6. Processing method: Forged and Rolled

Product Details

The ASTM B 348 Industrial Titanium Rod is a premium-grade titanium product specifically designed for demanding industrial environments. Manufactured in accordance with ASTM B348 standards, it ensures excellent purity, high strength-to-weight ratio, and outstanding corrosion resistance. This titanium rod is ideal for applications in chemical processing, power generation, marine systems, aerospace components, and medical devices, where reliability and performance are critical.

Titanium metal are light in weight, high in strength and superior in mechanical properties.It can be processed into various forms . Chdymetal have more than 30year's experience in non-ferrous metals industry, we can supply ASTM B 348 industrial titanium rod with various form and grade so welcome to contact for more details.

Specification

1. Product name: ASTM B 348 industrial titanium rod

2. Grade: Gr1 Gr2,Gr5,Gr7,Gr5 Ell,Gr9, Gr12

3. Size: Dia(4mm-350mm)*Length(≤3000mm)

4. Standard: ASTMB348,ASTMF67,ASTMF136

5. Type: Round, Square, Hexagon

6. Processing method: Forged and Rolled

7. Package Terms: Moisture-proof cloth, foam cotton inside, wooden case outside.

8. Shipping Terms:Express,Air,Shipping or as your choice.

9. Payments Terms: 30% TT in advance, 70% balance before shipment

ASTM B 348 Industrial Titanium Rod Application

1. Electronic products- Titanium rods can be used to manufacture electronic products because they have good electrical conductivity and can effectively prevent electronic products from being damaged or interfered with.

2. Aerospace-Titanium rods can be used to manufacture aerospace components, as well as complex structures such as engine compartments and internal propulsion devices of engines.

3. Medical equipment- Titanium rods can also be used to manufacture medical equipment. Through its corrosion resistance, it can effectively prevent damage to the human body.

Titanium Rod Common Stock

You can find the normal stock always and usually we can arrange delivery on the same day.we will also support your sample order.

|

Grade |

Standard |

Specification (mm) |

|

Gr2 |

ASTM B 348 |

Dia 8*L3000 |

|

Gr2 |

ASTM B 348 |

Dia 4*L1000 |

|

Gr2 |

ASTM B 348 |

Dia9-12mm*L1165-2340 |

|

Gr2 |

ASTM B 348 |

Dia20*3010 |

|

Gr2 |

ASTM B 348 |

Dia15-22*L1085-2030 |

|

Gr5 |

ASTM F136 |

Dia 10*L3000 |

|

Gr5 |

ASTM F136 |

Dia 8*L3000 |

|

Gr5 |

ASTM F136 |

Dia 14*1970 |

Manufacturing & Processing Capability

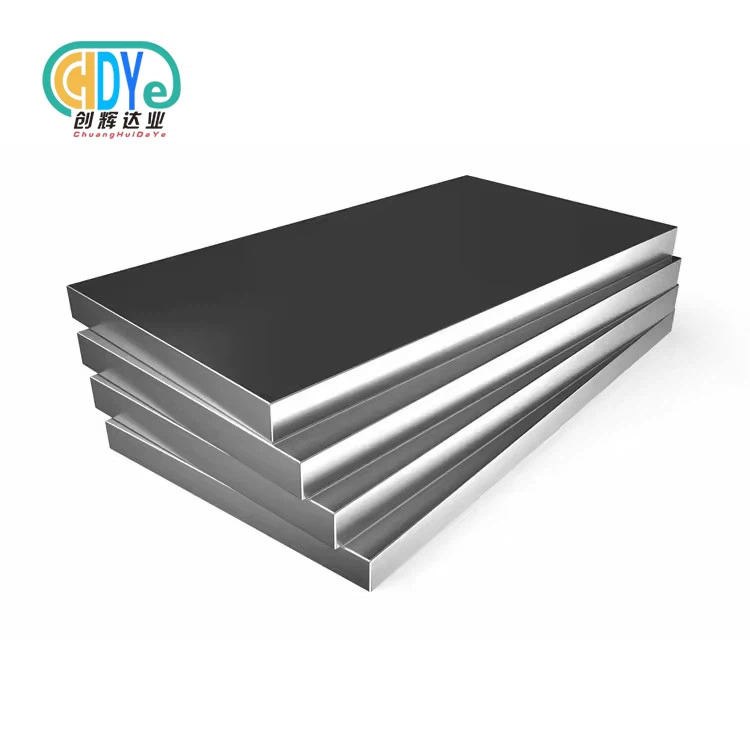

The manufacturing of the ASTM B 348 Industrial Titanium Rod integrates advanced metallurgical control with precision processing technology. Starting from high-purity titanium sponge, the material undergoes multiple stages of melting, forging, and hot rolling to ensure fine grain structure and consistent mechanical performance. Our production line is equipped with vacuum arc remelting (VAR) furnaces, rotary forging machines, and precision CNC lathes that guarantee dimensional accuracy and superior surface finish.

We offer flexible processing options including annealing, straightening, cutting, and surface polishing to meet various industrial requirements. Each rod is inspected by ultrasonic and eddy-current testing systems to eliminate internal defects and ensure full structural integrity. With diameter capability ranging from 6 mm to 300 mm and length up to 6000 mm, our plant supports both standard and customized specifications for global clients.

|

|

|

|

|

|

|

|

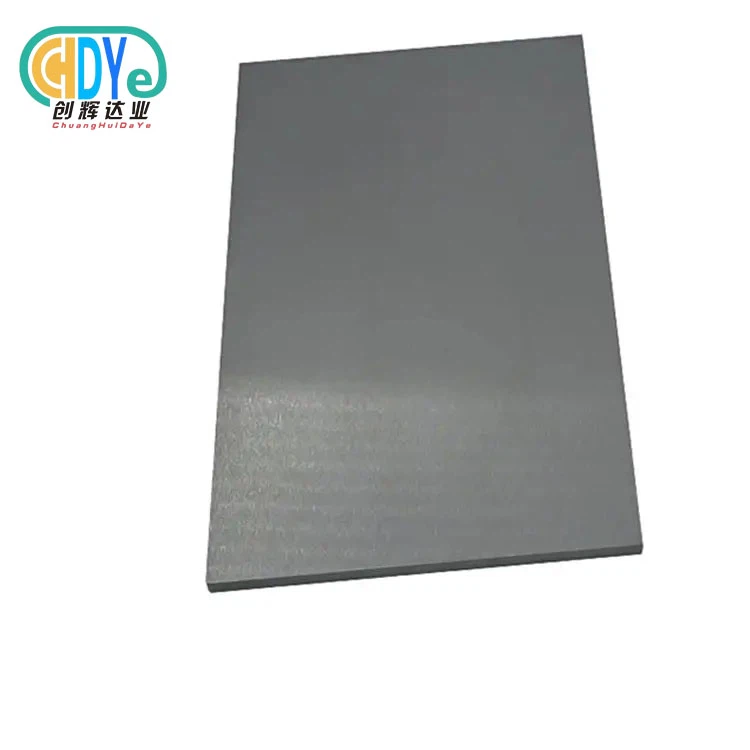

Surface & Mechanical Performance

Each titanium rod undergoes surface polishing or pickling to deliver a clean, smooth finish. The surface roughness and oxide layer thickness are strictly monitored. Typical mechanical properties include tensile strength ≥ 345 MPa, yield strength ≥ 275 MPa, and elongation ≥ 20%. These parameters ensure excellent machinability, weldability, and fatigue resistance in long-term operation.

Quality Assurance

All titanium rods are manufactured under ISO 9001:2015 and AS9100 quality systems. Every batch undergoes chemical composition analysis, mechanical property testing, and nondestructive inspection before delivery. Full traceability is maintained through mill test certificates (MTC) in accordance with EN 10204 3.1 standards.

Application Advantages

This titanium rod exhibits superior corrosion resistance in seawater, chlorine, and acid environments, making it a reliable choice for offshore platforms, chemical reactors, and condenser tubing. Its low density and non-magnetic nature also make it suitable for medical implants and aerospace fasteners where precision and biocompatibility are essential.

Be used in a wide range of industries.

Metallurgy and Special Steel

Electronics and Semiconductors

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

R&D and Customization

Our engineering team provides customized titanium rod solutions based on specific industry requirements. We offer tailored alloy compositions, heat treatments, surface finishing, and tolerance adjustments to optimize performance in special working environments. OEM and ODM services are available for global clients.

Packaging & Logistics

Titanium rod will be packed into wooden boxes with soft foam material inside to ensure that the products will not shift inside the cases and safety during transportation.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Global Cooperation& Certification

Our titanium products are exported to over 40 countries across Europe, America, and Asia. With international certifications such as ISO, SGS, and TUV, we have built long-term cooperation with industries in aerospace, energy, and medical technology. We welcome global partners to join us in advancing high-performance titanium applications.

|

|

|

|

|

|

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email