- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

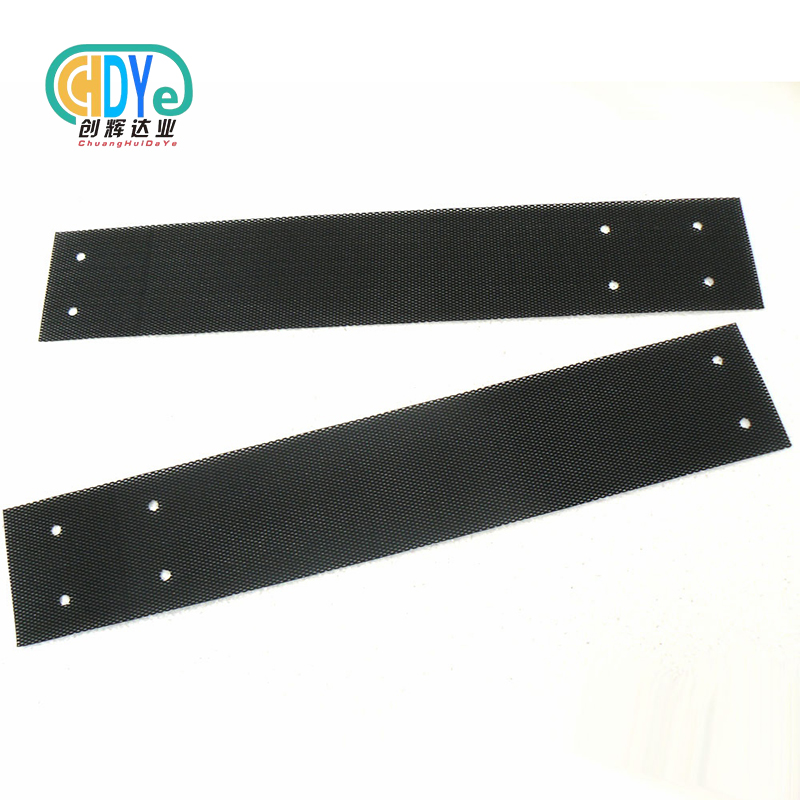

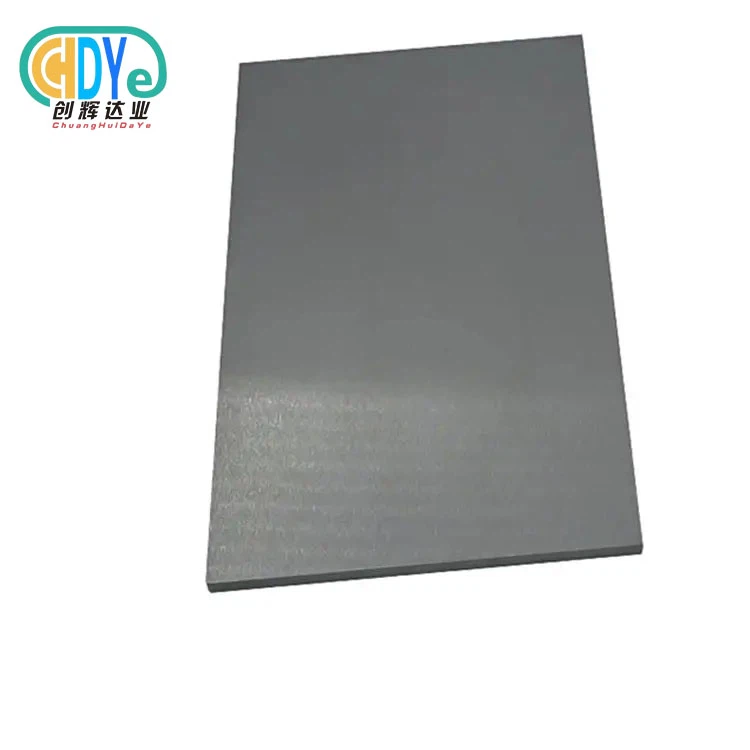

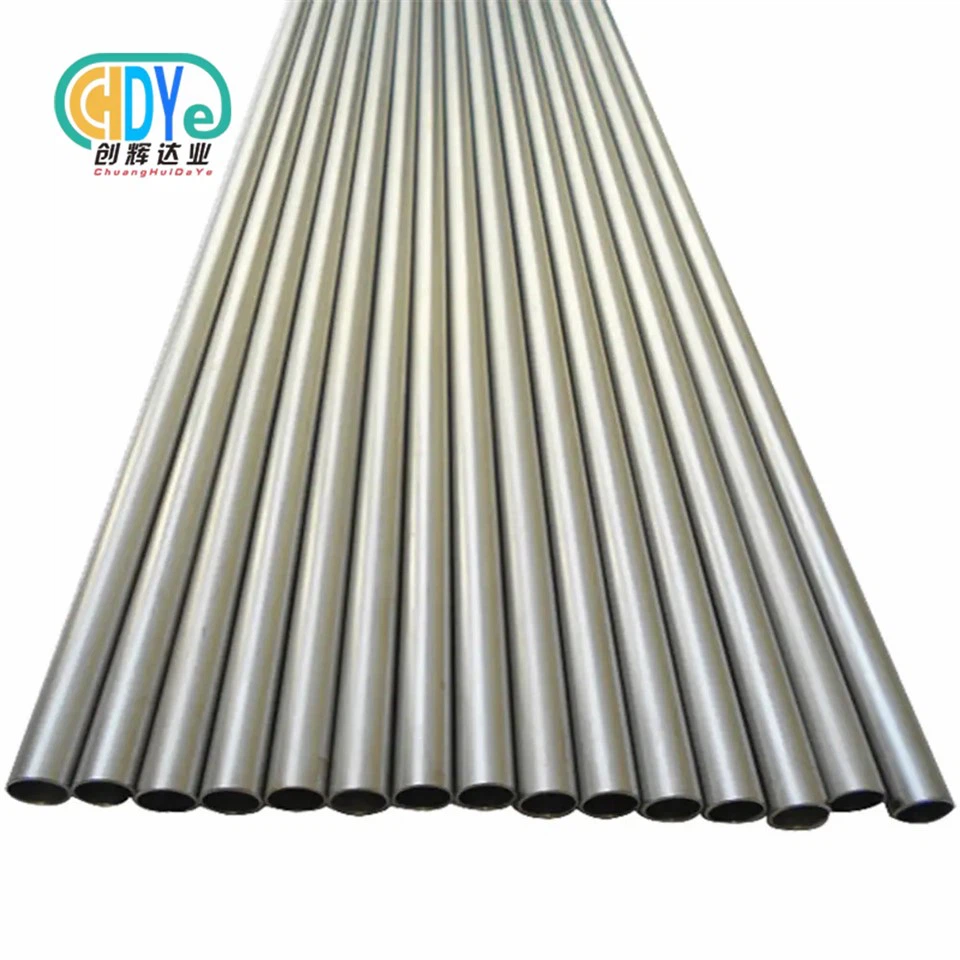

niobium titanium alloy plate

2. Standard: ASTM B393

3. Surface: Polished, annealed, Cold-rolled bright

4. Grade: UNS R04200, UNS R04210 ,C103 Alloy, 45Nb Alloy (Nb-55Ti), Nb-7.5Ta, Nb-47Ti, Nb-50Ti

Product Introduction

Our niobium titanium alloy plate represents cutting-edge metallurgy technology designed for the most demanding aerospace and electronics applications. Combining the exceptional properties of niobium and titanium, this advanced alloy delivers outstanding performance in superconducting magnets, medical implants, and high-tech electronics. With over 30 years of expertise in rare metal processing, Shaanxi Chuanghui Daye Metal Material Co., Ltd. produces precision-engineered plates that meet the strictest industry standards. You'll discover unmatched reliability and performance in every plate we manufacture.

Key Features and Benefits

- Superior Conductivity: Excellent superconducting properties for magnetic resonance imaging and particle accelerators

- Exceptional Biocompatibility: Perfect for medical implants and prosthetic applications

- High Corrosion Resistance: Maintains integrity in harsh chemical environments

- Excellent Formability: Easy to machine and fabricate into complex shapes

- Temperature Stability: Performs consistently across extreme temperature ranges

- Lightweight Design: Lower density compared to other high-performance alloys

Technical Specifications

|

Purity |

99.95% |

|

Technics |

Cold rolled |

|

Standard |

ASTM B393 / ASME SB393 |

|

Density |

8.57g/cm3 |

|

Application |

Industrial |

| Grade |

45Nb Alloy (Nb-55Ti), Nb-7.5Ta, Nb-47Ti, Nb-50Ti |

|

Specification |

Customized |

|

Hardness |

Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. |

|

Certification |

ISO 9001:2015 |

| Delivery time |

Normal time is 10-15 days |

| Payment term |

30%TT in advance, 70% balance before shipment |

Available Grades and Materials

We offer various niobium-titanium compositions to meet your specific requirements:

- Nb-47Ti: Standard superconducting grade

- Nb-50Ti: Enhanced ductility variant

- Custom Alloys: Tailored compositions for specialized applications

Each grade undergoes rigorous quality control to ensure consistent performance across different batches.

Manufacturing Process

Our advanced manufacturing process ensures exceptional quality:

- Raw Material Selection: Premium-grade niobium and titanium sourcing

- Vacuum Melting: Controlled atmosphere prevents contamination

- Hot Rolling: Precise thickness control and grain structure optimization

- Heat Treatment: Stress relief and property enhancement

- Cold Rolling: Final dimensional accuracy and surface finish

- Quality Testing: Comprehensive inspection and certification

|

|

|

|

|

|

|

|

Applications and Industries

Our niobium titanium alloy plate serves diverse high-tech sectors:

- Medical Technology: MRI machines, medical implants, surgical instruments

- Aerospace Industry: Jet engine components, spacecraft parts, satellite systems

- Electronics Sector: Superconducting devices, research equipment, quantum computing

- Energy Applications: Fusion reactors, particle accelerators, power transmission

- Research Facilities: Laboratory equipment, scientific instruments, experimental devices

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

We maintain strict dimensional tolerances:

- Thickness Tolerance: ±0.05mm for thin plates, ±0.1mm for thick plates

- Width Tolerance: ±2mm standard, ±1mm precision grade

- Length Tolerance: ±5mm standard, ±2mm precision grade

- Flatness: ≤2mm per meter

- Surface Finish: Ra 0.8μm standard, Ra 0.4μm polished grade

Product Features in Detail

The unique microstructure of our plates provides exceptional performance characteristics. The niobium-titanium matrix creates fine precipitates that enhance superconducting properties while maintaining mechanical strength. You benefit from a material that combines the best attributes of both metals - niobium's chemical stability and titanium's lightweight properties.

Surface quality receives special attention during production. Our niobium titanium alloy plate features smooth, oxide-free surfaces that eliminate contamination risks in sensitive applications. The controlled grain structure ensures consistent properties throughout the entire plate thickness.

Quality Assurance and Testing

Every plate undergoes comprehensive testing:

- Chemical Composition Analysis: Spectroscopic verification

- Mechanical Property Testing: Tensile strength, elongation, hardness

- Dimensional Inspection: Precision measurement and documentation

- Surface Quality Assessment: Visual and instrumental examination

- Superconducting Property Verification: Critical temperature and current testing

|

|

|

Niobium alloy plate Order Processing

1.First contact us to provide the grade, size ,quantity and standard or any special requirements

2.we will reply you the quotation with delivery time in 3 hours.

3.reach an agreement the buyer arrange the prepayment

4. when we get your payment we will arrange production asap and share you the production progress.

5.when production finished, will give buyer the actual weight of the products, then the buyer arrange balance payment

6. Arrange shipment according to the most economical form we have agreed on

7.Meanwhile send buyer the material certificate

8. Regular after-sales service to know the actual product usage

Packaging and Shipping

Your plates receive careful packaging to prevent damage during transit:

- Individual Wrapping: Protective film prevents surface contamination

- Cushioned Packaging: Shock-absorbing materials protect against impact

- Moisture Protection: Sealed containers maintain material integrity

- Clear Labeling: Detailed identification for easy handling

We ship worldwide with trusted logistics partners, ensuring safe delivery to over 50 countries including the United States, Germany, South Korea, and Singapore.

Why Choose Us

With three decades of rare metal expertise, we bring unmatched knowledge to every project. Our location in China's "Titanium Capital" provides access to premium raw materials and specialized manufacturing capabilities. You receive competitive pricing, on-time delivery, and customer-focused service that builds lasting partnerships.

Our commitment to continuous improvement means you always get the latest advancements in niobium titanium alloy plate technology. We invest in state-of-the-art equipment and ongoing staff training to maintain our position as industry leaders.

|

|

|

|

|

|

FAQs

Q: What makes niobium-titanium alloys superior for superconducting applications?

A: The combination creates optimal flux pinning characteristics and maintains superconductivity at higher magnetic fields compared to pure materials.

Q: Can you provide certification documents with shipments?

A: Yes, we provide complete material certificates including chemical composition, mechanical properties.

Q: What is your typical lead time for standard plates?

A: Standard products ship within 1-2 weeks, while custom specifications may require 2-3 weeks depending on complexity.

Contact Us

Ready to discuss your niobium titanium alloy plate requirements? Our technical experts are here to help you select the perfect solution for your application. Contact us today at info@chdymetal.com for detailed quotations, technical specifications, or to schedule a consultation with our metallurgy specialists.

Learn about our latest products and discounts through SMS or email