- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

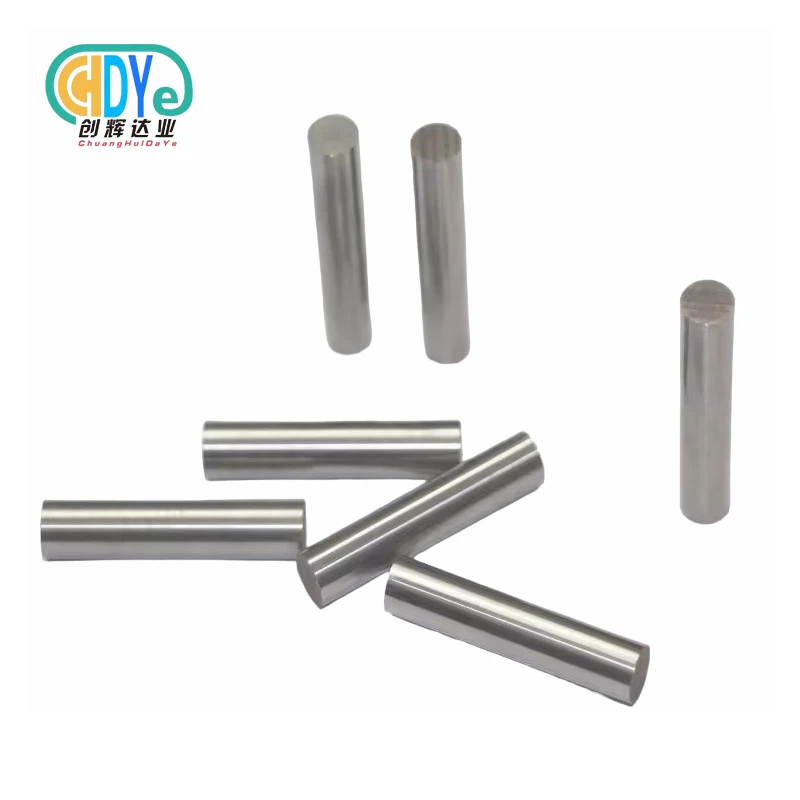

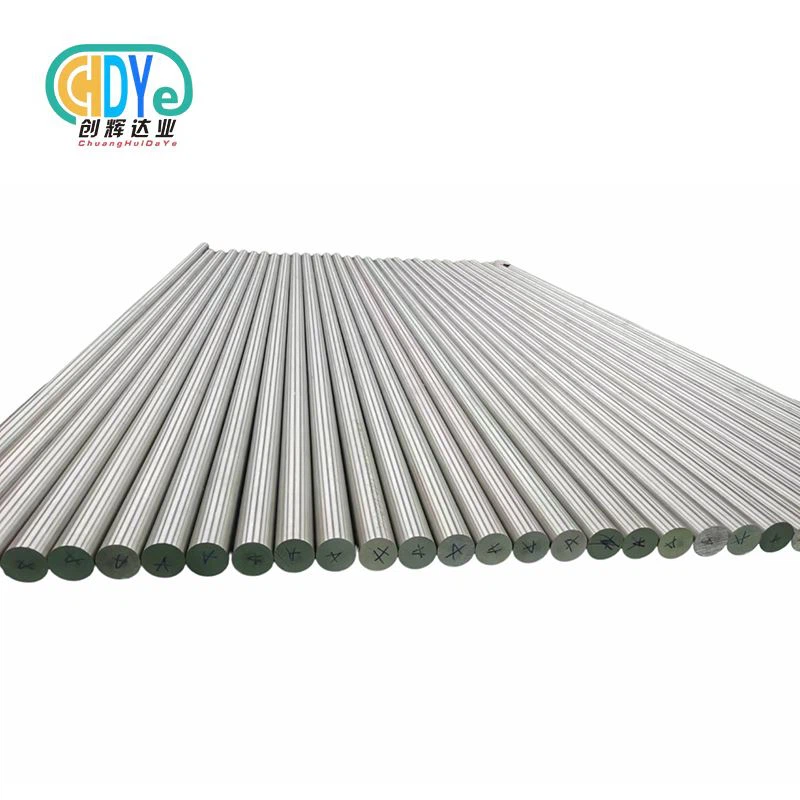

Tungsten Filament And Wire

Product Introduction

Tungsten has the highest melting point and lowest vapor pressure of all metals, and at the temperatures over 1650°C has the highest tensile strength.Tungsten is the most useful material used in vacuum evaporation technique, due to its special properties and cost factor.Tungsten filament and wire widely used in lighting, electronics, vacuum technology and welding.

The production process includes material selection, pressing, wire drawing, heat treatment and processing. First, high-purity tungsten raw materials are selected, impurities are removed and pressed into wires, and then drawn through multiple wire drawing machines to obtain tungsten wires with gradually decreasing diameters. Subsequently, high-temperature treatment is performed to eliminate stress and improve mechanical properties, and finally, curling, cutting and other processing are performed to meet the application needs of different fields.

Characteristics

1. High melting point: The melting point of tungsten wire is as high as 3410℃ (or 3422℃), which is the highest among all metals, making it very suitable for use in high temperature environments.

2. High hardness: The hardness of tungsten wire is very high, with a Vickers hardness of up to 3430 MPa. Compared with steel, its hardness is about 15 times that of steel, and it has excellent tensile resistance and wear resistance.

3. High strength: Tungsten wire has high strength, and its tensile strength can be maintained well even in high temperature environments, which makes it widely used in occasions requiring high-strength components.

4. High resistivity: The resistivity of tungsten wire is relatively large, which makes it have special applications in the fields of electronics and electric heating.

5. Low vapor pressure and slow evaporation rate: Tungsten wire evaporates slowly at low vapor pressure, which allows it to remain stable for a long time at high temperatures.

6. Wear resistance, impact resistance, acid and alkali resistance: Tungsten wire also has good wear resistance, impact resistance, acid and alkali resistance, which further broadens its application areas.

7. High density: The density of tungsten wire is 19.25 g/cm³ (or 19.3 g/cm³), which is very close to gold, and has high weight and stability.

Application Advantages

Tungsten Filament And Wire are widely applied in industries that require stable performance under extreme heat and vacuum environments. Typical applications include:

- Lighting Industry: Used as filaments in incandescent lamps, halogen lamps, and other lighting sources due to tungsten’s superior thermal emission properties.

- Electronics: Utilized in electron tubes, cathodes, and grid components for vacuum electronic devices.

- Aerospace and Defense: Employed in heating elements and ignition systems for propulsion and testing environments.

- Semiconductor and Vacuum Equipment: Serves as support and heating wires in high-temperature furnaces and crystal growth systems.

- Medical and Analytical Instruments: Used for X-ray tube filaments and heating elements in laboratory devices requiring precision and reliability.

Be used in a wide range of industries.

Steel industry

Electronic devices

Furnace components

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

The production of Tungsten Filament And Wire at Shaanxi Chuanghui Daye follows a strict and precise process designed to maintain purity, homogeneity, and structural stability:

- Raw Material Selection: High-purity tungsten powder is screened to ensure consistent particle size and quality.

- Powder Pressing and Sintering: The powder is compacted into billets and sintered in a hydrogen or vacuum atmosphere to achieve high density.

- Rolling and Swaging: Hot and cold working processes improve mechanical strength and refine grain structure.

- Drawing Process: The billets are drawn through multiple dies to reach precise diameters, achieving uniform filament or wire thickness.

- Annealing and Straightening: The wires are annealed to enhance ductility and relieve internal stress.

- Surface Treatment: Cleaning, polishing, and oxidation control are performed to ensure a smooth and bright surface.

- Final Testing and Packaging: Every spool or coil undergoes rigorous inspection before being packed for global shipment.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Shaanxi Chuanghui Daye ensures superior quality and reliability in every Tungsten Filament And Wire through comprehensive testing and inspection procedures:

- Chemical Composition Testing: Conducted with spectrometers to ensure high tungsten purity and low impurity levels.

- Dimensional Accuracy: Measured with laser and micrometer tools for precise diameter control.

- Tensile Strength & Elongation Tests: Verify mechanical stability under thermal and stress conditions.

- Microstructure Examination: Ensures fine grain uniformity and excellent ductility.

- Surface Cleanliness & Finish Checks: Guarantee smooth and oxidation-free wire surfaces.

All inspection processes comply with ISO 9001:2015 and ASTM standards to ensure reliability and traceability.

R&D and Customization

With strong research capabilities and advanced production facilities, Shaanxi Chuanghui Daye provides tailored solutions to meet specific client requirements:

- Custom diameters (from 0.02 mm to 3.0 mm).

- Specialized tungsten grades or doped wires for higher strength or improved recrystallization resistance.

- Surface finishes: black, cleaned, or polished.

- Coil, spool, or straight-cut formats.

- Material consultation and prototype services.

Packaging & Global Logistics

We ensure safe and professional packaging for worldwide delivery:

- Packaging: Vacuum-sealed bags or anti-rust film with foam cushioning, packed in wooden boxes for export.

- Labeling: Each package is marked clearly with grade, size, batch number, and inspection status.

- Logistics: Global delivery via air, sea, or express with reliable and timely service.

All packaging adheres to international export standards to ensure that the Tungsten Filament And Wire arrives in excellent condition.

|

|

|

|

|

|

|

|

|

|

|

|

OEM & Customization Service

Shaanxi Chuanghui Daye provides flexible OEM and ODM services, offering:

- Custom size and tolerance production.

- Private branding and labeling options.

- Prototype and small-batch manufacturing.

- Technical guidance and after-sales support.

We are dedicated to delivering cost-effective and dependable products to help clients strengthen their market competitiveness.

Inspection Process

Each batch of Tungsten Filament And Wire undergoes a strict inspection process to ensure full compliance with technical and performance standards:

- Raw Material Chemical Analysis

- Sintering Quality Check

- Dimensional and Surface Examination

- Mechanical Strength and Ductility Testing

- Final Visual Inspection and Certification

Every step is recorded and traceable under the ISO 9001:2015 system.

Why Choose Us

- Over 30 Years of Experience: Expertise in tungsten, molybdenum, and other refractory metal production.

- Advanced Equipment: Electron beam furnaces, rolling machines, precision drawing systems.

- Certified Quality: ISO 9001:2015 and ASTM standard compliance.

- Fast Global Delivery: Orders can be processed and shipped within 7 days.

- Technical Expertise: Professional support for material selection and process optimization.

Shaanxi Chuanghui Daye is your reliable partner for precision-engineered Tungsten Filament And Wire products worldwide.

|

|

|

|

|

|

FAQs

Q1: What are the standard diameters available?

A1: We offer diameters from 0.02 mm to 3.0 mm, customizable to your exact specifications.

Q2: What surface finishes can be provided?

A2: Black (as-drawn), cleaned, and polished finishes are available depending on application needs.

Q3: What is the purity level of your tungsten wire?

A3: We guarantee tungsten purity above 99.95%, with trace element control.

Q4: Do you provide small-batch or prototype orders?

A4: Yes, we support sample and prototype production to assist customers in testing and design.

Q5: How long is your typical delivery time?

A5: Standard products can be shipped within 7 days; custom orders are based on specification and quantity.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email