- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

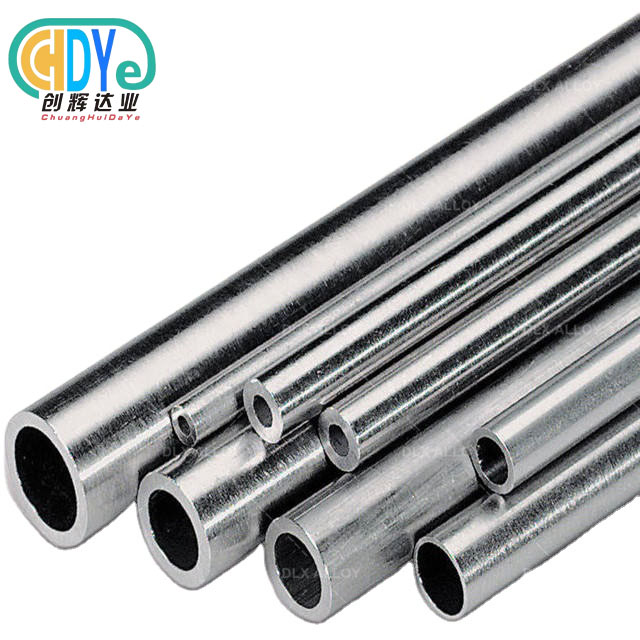

Mmo Titanium Anode Plate

Mmo titanium anode plate

Chdymetal can provide various titanium anodes, customized is accepted. titanium anodes use pure titanium material as substrate, has high anti-corrosion and high catalytic activity. MMO coated anode has long working life .For the important, the substrate could be reused.

|

Material |

Gr1 titanium as substrate, Mixed Ruthenium-Iridium oxide, Ir-ta , Ru-ir-Sn, platinum as coating |

|

Coating Thickness |

8~12micron |

|

Parameter |

1. Current density≤2000A/M2 2. Temperature<60°C 3. PH 0.1~14 4. Max content of Fluoride ion is 200PPM |

|

Dimension & Shape |

1. Plate/Tube/Rod/Mesh shape, different dimension is available 2. or according to client's drawing |

|

Advantages |

1. Effective and environmental 2. High current efficiency 3. High anti-corrosion property 4. Long working life 5. Keep the operating voltage stably 6. Small size & light weight 7. Titanium base can be reused |

Precautions for product use

- In most industries, we recommend the normal working current density is less than 2000A/m2.

- The electrolyte can not contain cyanide ion, fluorine ion.

- Reason: the presence of these substances will serious corrosion of titanium substrate.

- Distance between anode to cathode can be set according to the specific circumstances, generally in the 5-25mm.

- Polarity reversal is prohibited,descaling use pickling is the best choice.

- The temperature of electrolyte should not be too high, normal temperature 25-40℃

- The most important is when installation, maintenance, handling process should be avoid scratch.

Application Advantages

The MMO Titanium Anode Plate (Mixed Metal Oxide Titanium Anode Plate) manufactured by Shaanxi Chuanghui Daye Metal Material Co., Ltd. is designed for high-efficiency electrochemical performance and long-term stability. Using a titanium substrate coated with mixed metal oxides such as IrO₂, RuO₂, and Ta₂O₅, it provides exceptional conductivity, durability, and corrosion resistance in aggressive chemical environments.

Main Advantages:

- Superior Corrosion Resistance: Resistant to strong acids, alkalis, and chloride environments for long-term industrial operation.

- High Electrochemical Activity: Low overpotential and high current efficiency ensure optimized energy consumption.

- Extended Service Life: Stable oxide coating minimizes wear, providing reliable operation over thousands of hours.

- Stable Performance: Uniform current distribution guarantees consistent output and uniform coating in electroplating and chlorination systems.

- Environmentally Friendly: Free from lead and mercury, fully compliant with RoHS and environmental protection standards.

- Wide Application Range: Used in electrochlorination, electroplating, wastewater treatment, cathodic protection, and chlorine dioxide generation systems.

Be used in a wide range of industries.

Seawater electrolysis

Marine aquaculture

Chlor-alkali industry

Cathodic protection

Electroplating industry

Non-ferrous metal electrolytic extraction

Manufacturing & Process Flow

1. Select suitable Gr1 titanium plate as substrate and cut into customized size.

2. Substrate surface treatment including surface sandblasting, acid Washing-Brushing coating -Sintered -Oxidation-Annealed Repeat this process multiple times according to the coating thickness.

3. Inspection the surface and coating no scratching.

|

|

|

|

|

|

|

|

Quality Control & Inspection

At Chuanghui Daye, quality is not just a promise—it is a process integrated into every production stage. Our MMO anodes are manufactured and inspected under strict compliance with ISO 9001:2015 standards.

Inspection Coverage Includes:

- Raw Material Verification: Each titanium plate is tested for purity, hardness, and microstructure uniformity.

- Coating Thickness Test: Coating uniformity is checked using advanced optical and electrochemical testing.

- Adhesion & Bonding Test: Conducted to confirm no peeling or delamination under high current density.

- Electrochemical Performance Test: Simulated cell tests to evaluate chlorine/oxygen evolution potential.

- Dimensional & Visual Inspection: Surface smoothness, coating coverage, and edge quality are checked thoroughly.

- Final Approval & Documentation: A test report and batch identification number are provided with every shipment.

R&D and Customization

With a highly skilled engineering team and advanced R&D laboratories, Shaanxi Chuanghui Daye continues to optimize MMO coating formulations and electrode structures for various industrial demands.

Our R&D Focus:

- Development of long-life MMO coatings for high chlorine concentration environments.

- Improved coating adhesion for large-scale electrolytic systems.

- Performance simulation and analysis for anode lifespan extension.

- Collaboration with research institutes to develop new rare metal coating systems.

Customization Options:

- Coating composition: Ir–Ta, Ru–Ir, or Ta–Ir MMO coatings

- Substrate grade: GR1, GR2, or customized titanium alloys

- Shape: Plate, mesh, tube, or rod type

- Size: Up to 1200 × 1000 mm, or customized dimensions

- Connection: Titanium welding rod, bolt, or conductive bar type

Packaging & Global Logistics

Every MMO Titanium Anode Plate is packed with care to ensure safe transportation from China to over 50+ export markets worldwide.

Packaging Details:

- Inner layer: Vacuum-sealed or anti-rust protective film

- Middle layer: Foam or bubble wrap for shock absorption

- Outer layer: Export-grade wooden cases with waterproof treatment

- Labeling: Product model, coating type, batch number, and test certificate

Logistics Advantages:

- Air Freight: Fast delivery for urgent projects (3–7 days)

- Sea Freight: Cost-effective option for bulk orders

- Land Transport: Safe domestic and regional deliveries

- All logistics partners are internationally certified to ensure traceability and timely delivery.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

We provide full OEM and ODM services to support project-specific needs and global client requirements.

Service Scope:

- Customized coating systems and anode geometry based on electrolyte chemistry

- Prototype design and testing for new applications

- Small-batch or large-scale manufacturing flexibility

- Private labeling and branding support

- Technical consultation and maintenance training

Our team collaborates closely with engineers and end-users to develop optimal electrode solutions for long-term industrial performance.

Inspection Process

To ensure 100% product reliability, every MMO Titanium Anode Plate passes through a well-defined inspection system before shipment.

Inspection Workflow:

- Raw material certificate validation

- Dimensional inspection using precision instruments

- Surface and coating thickness analysis

- Adhesion strength verification

- Electrochemical performance testing

- Visual inspection for coating defects

- Packaging verification and labeling confirmation

- Final review and approval by the QA department

Comprehensive inspection records are archived and traceable for each production batch.

Why Choose Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd. stands out as a trusted supplier of titanium-based anodes due to its technological strength and customer-oriented approach.

Our Advantages:

- Over 30 years of rare metal industry expertise

- Certified ISO 9001:2015 quality system

- Advanced coating and machining equipment

- 50+ countries export experience

- Fast delivery—7-day average turnaround

- OEM/ODM support with complete technical documentation

- Dedicated customer service team providing full technical support

We are committed to offering durable, high-performance, and cost-effective MMO titanium anodes for industrial electrochemical systems worldwide.

|

|

|

|

|

|

FAQs

Q1: What is the typical lifespan of an MMO Titanium Anode Plate?

A1: Depending on the coating type and operating environment, the service life typically ranges from 3 to 10 years or longer.

Q2: Can the anode be used in seawater electrolysis or chlor-alkali systems?

A2: Yes, our MMO titanium anodes are widely used in seawater electrochlorination, chlor-alkali production, and brine electrolysis systems.

Q3: Do you provide customized coating compositions?

A3: Absolutely. We offer Ir–Ta, Ru–Ir, and mixed MMO coatings according to your current density and electrolyte requirements.

Q4: What are your standard dimensions for MMO titanium plates?

A4: Standard sizes include 300×300 mm, 500×600 mm, and 1000×1200 mm, but custom dimensions are fully supported.

Q5: How is the product shipped internationally?

A5: All anodes are vacuum-packed and delivered via air or sea freight with full export documentation and tracking.

Q6: Can you provide test reports and quality certificates?

A6: Yes, every order is accompanied by inspection certificates, coating composition reports, and ISO quality documentation.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email

_1766371400851.webp)