- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

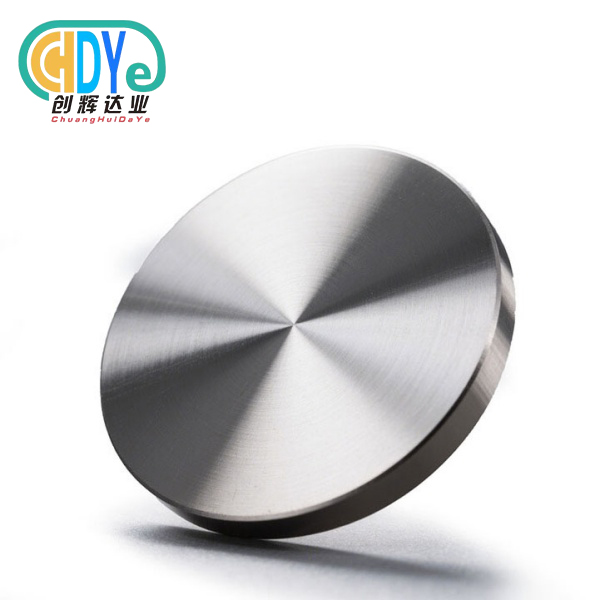

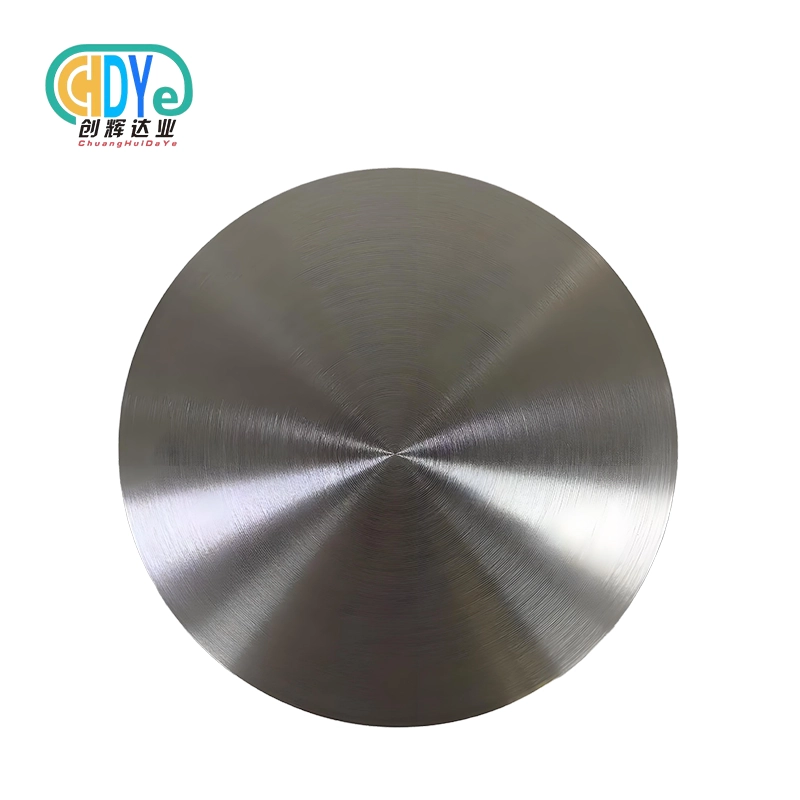

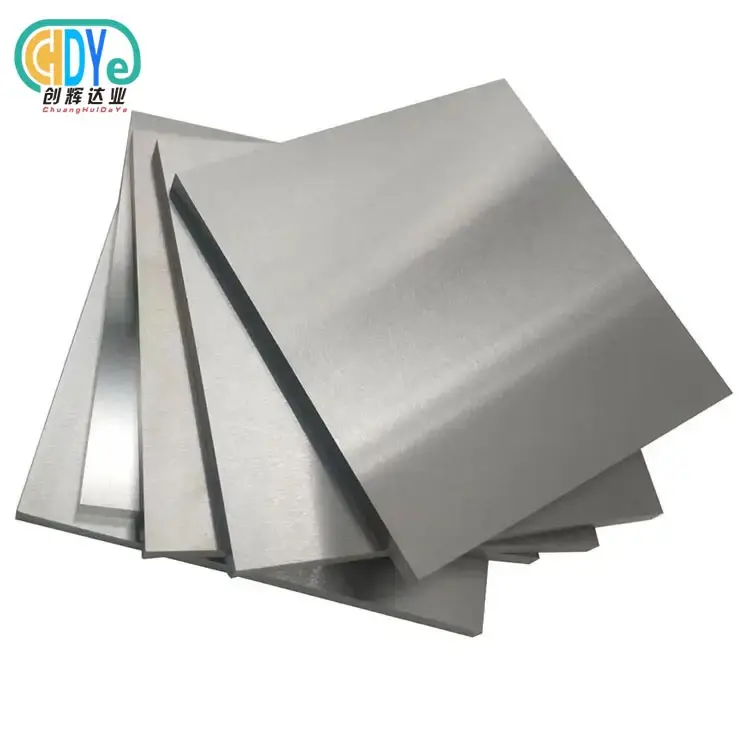

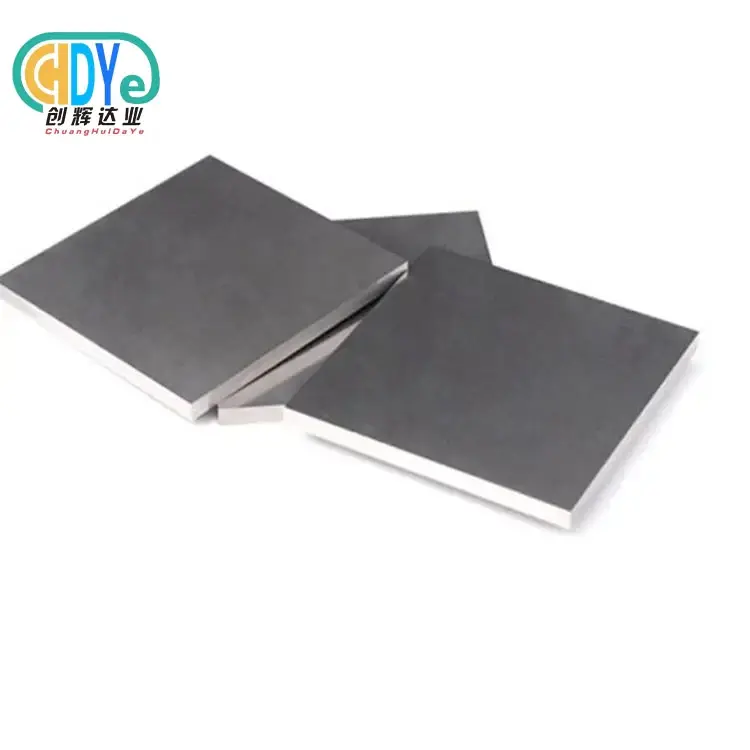

High Purity Molybdenum Sheet

2.Size:thk.0.1~25mm x 30-500 x L<000mm

Product Introduction

The High Purity Molybdenum Sheet produced by Shaanxi Chuanghui Daye Metal Material Co., Ltd. is designed for applications requiring exceptional strength, stability, and resistance to high temperatures. Manufactured using advanced smelting and rolling technologies, the sheet delivers uniform grain structure, excellent flatness, and outstanding surface quality. With a molybdenum purity exceeding 99.95%, it provides superior thermal conductivity, corrosion resistance, and dimensional precision for demanding industrial environments.

This product is particularly suited for use in vacuum furnaces, semiconductor manufacturing, sputtering targets, and high-temperature heating components. By meeting strict international standards such as ASTM B386, our molybdenum sheets ensure long-term reliability and consistent performance under extreme operating conditions.

Molybdenum is an exceptional material that can satisfy the most demanding requirements due to its high melting point, low coefficient of thermal expansion, and excellent thermal conductivity. Chdymetal provide high quality customized molybdenum sheet or it's alloy for industrial application.

|

Product name |

High purity Molybdenum sheet |

|

|

Purity |

99.95% |

|

|

Density |

10.2g/cm3 |

|

|

Melting Point |

2610℃ |

|

|

Standard |

ASTM B386 |

|

|

Size |

thk.0.1~25mm x w x L |

|

|

Property |

Anti-corrosion, high temperature resistance |

|

|

MOQ |

1pc or 1kg |

|

|

Delivery time |

7-10 days |

|

Thickness(mm) |

Tolerance (mm) |

Width (mm) |

Tolerance (mm) |

Length (mm) |

Tolerance (mm) |

|

0.1 - 0.2 |

±0.02 |

30 -300 |

±3 |

50 -1000 |

±3 |

|

> 0.2 -1.0 |

±0.03 |

50 -500 |

±3 |

50 -1000 |

±3 |

|

> 1.0 - 4.0 |

±0.03 |

50 -500 |

±3 |

50 -1000 |

±3 |

|

> 4.0 - 20 |

±0.04 |

50 -500 |

±4 |

50 -1000 |

±4 |

|

> 0.6 - 1.0 |

±0.06 |

50 -500 |

±4 |

50 -1000 |

±4 |

|

>1.0 - 2.0 |

±0.10 |

50 -610 |

±5 |

50 -1000 |

±5 |

|

>2.0 - 4.0 |

±0.20 |

50 -610 |

±5 |

50 -1000 |

±5 |

|

>4.0 - 6.0 |

±0.30 |

50 -610 |

±5 |

50 -800 |

±5 |

|

>6.0 - 20 |

±0.60 |

50 -610 |

±5 |

50 -800 |

±5 |

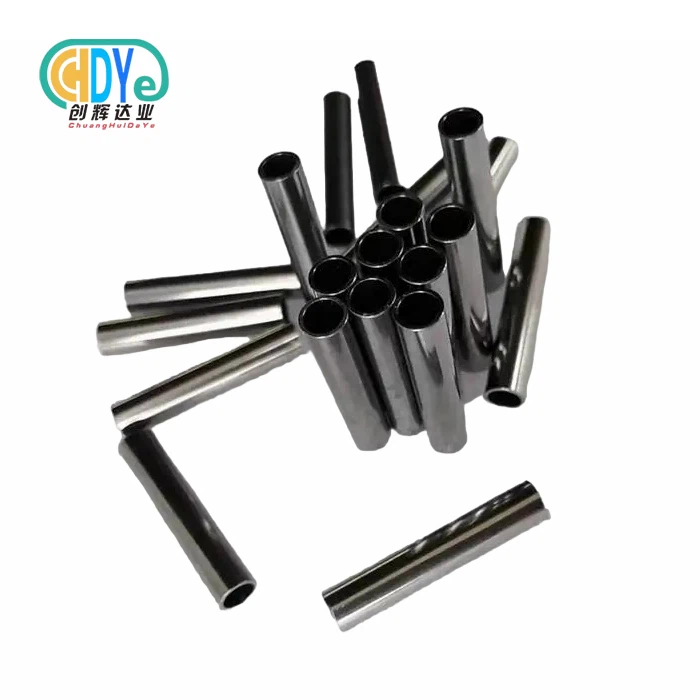

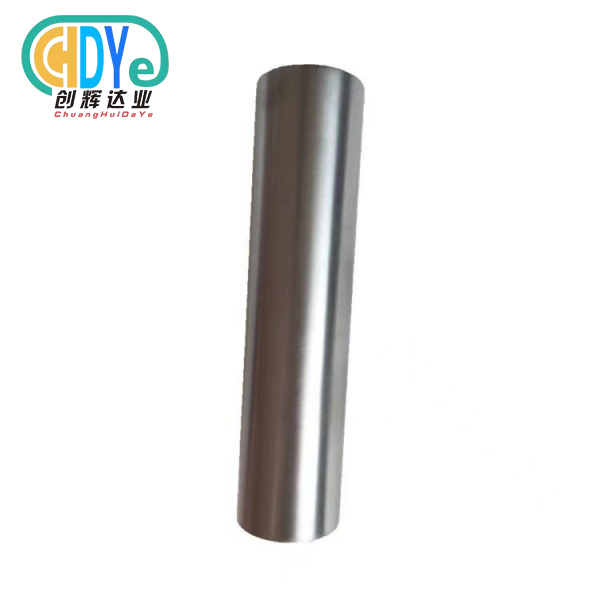

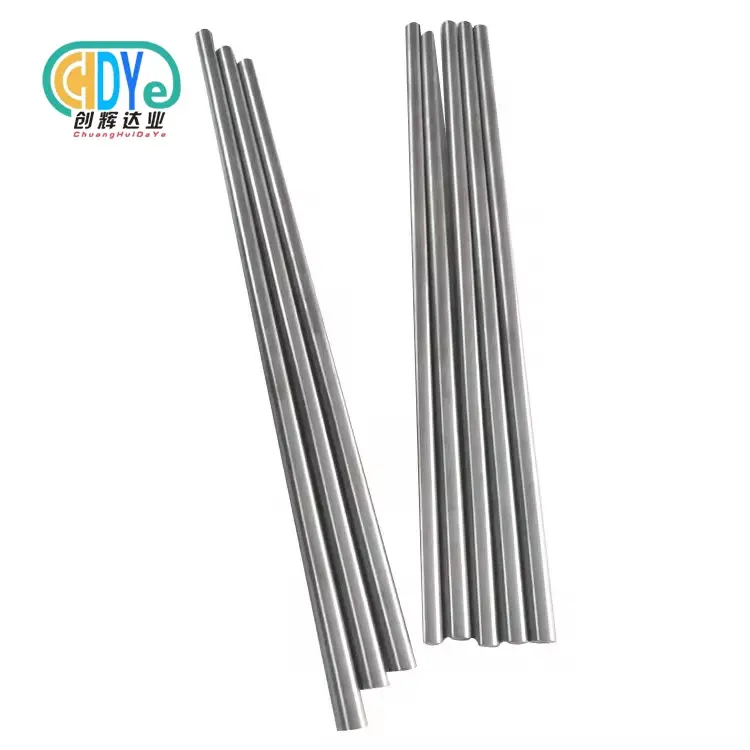

Our Products

Application

The High Purity Molybdenum Sheet is widely utilized across a variety of industries due to its outstanding combination of physical and chemical properties:

- Electronics and Semiconductor Industry: Used as a base material for sputtering targets, heat shields, and electronic packaging due to its excellent electrical and thermal conductivity.

- Metallurgical and Vacuum Furnaces: Ideal for structural parts, liners, and heating elements exposed to prolonged high-temperature environments.

- Aerospace and Defense: Suitable for thermal shields, nozzles, and high-stress structural components requiring stability under extreme conditions.

- Chemical and Energy Industries: Used in reactors and filtration systems for its corrosion resistance against strong acids and alkalis.

- Optical Coating and Thin Film Deposition: Provides a stable substrate that ensures uniform coating during vapor deposition and evaporation processes.

Be used in a wide range of industries.

Steel industry

Electronic devices

Furnace components

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

Molybdenum billet (raw materials) - inspection - hot - leveling and annealing - alkaline cleaning - inspection - vacuum annealing - - cold rolled - leveling - shear vacuum annealing - inspection - packing

Surface Treatment:

Hot-rolled alkaline cleaning surface

Electrolytic polish surface

Cold-rolled surface

Machined surface

|

|

|

|

|

|

|

|

Quality Control & Inspection

Quality is at the heart of Shaanxi Chuanghui Daye’s production philosophy. Every molybdenum product, including the High Purity Molybdenum Sheet, undergoes a strict quality control process covering:

- Raw material composition analysis by ICP and spectrometry

- Density and hardness testing

- Ultrasonic flaw detection

- Surface flatness and thickness measurement

- Dimensional tolerance verification

- Oxidation and corrosion resistance evaluation

The company operates under ISO 9001:2015 certification, ensuring traceability and consistency throughout production.

R&D and Customization

With over three decades of expertise in rare metal processing, our R&D department focuses on innovation in molybdenum material performance. We can customize High Purity Molybdenum Sheet according to customer specifications including:

- Thickness range: 0.05 mm – 50 mm

- Width: up to 600 mm

- Surface finish: polished, ground, or rolled

- Tolerances based on ASTM, GB, or customer drawings

We continually explore enhanced sintering techniques and alloy modifications to improve mechanical properties and oxidation resistance for specialized applications.

Packaging & Global Logistics

Each molybdenum sheet is carefully handled to ensure it reaches the customer in pristine condition.

- Packaging: Vacuum-sealed or wrapped with anti-rust film, protected by foam and packed in export-grade wooden crates.

- Marking: Each package carries clear labeling including product specifications, batch number, and inspection date.

- Shipping: We cooperate with global logistics providers for fast and safe air, sea, and land transportation.

Our logistics system ensures that every shipment of High Purity Molybdenum Sheet is delivered efficiently to clients across more than 50 countries.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Shaanxi Chuanghui Daye offers complete OEM and ODM services. Whether customers require small prototype runs or large-volume production, we provide:

- Tailored sizes and shapes based on drawings

- Material selection and engineering advice

- Prototype development and performance testing

- Laser cutting and CNC machining services

Our goal is to deliver flexible, cost-effective, and high-quality solutions that meet the evolving needs of international industries.

Inspection Process

To guarantee every shipment meets global quality standards, we implement a comprehensive inspection procedure:

- Incoming Material Test – Chemical composition verification.

- In-Process Control – Continuous measurement during rolling and annealing.

- Mechanical Test – Tensile strength, elongation, and hardness analysis.

- Dimensional Check – Thickness, width, and flatness confirmation.

- Final Audit – Surface integrity and labeling validation before dispatch.

All inspection data are recorded and stored for traceability, ensuring full compliance with ASTM B386 and customer-specific standards.

Why Choose Us

- Over 30 Years of Experience: Deep expertise in rare and refractory metals.

- Advanced Manufacturing Equipment: Electron beam furnaces, rolling mills, and precision machining centers.

- ISO 9001:2015 Certified: Strict quality assurance from raw material to finished product.

- Global Reach: Exported to over 50 countries worldwide.

- Custom Solutions: OEM/ODM services tailored to unique customer demands.

- Fast Delivery: 7-day turnaround for standard sizes and specifications.

By choosing Shaanxi Chuanghui Daye, you are partnering with a manufacturer dedicated to delivering precision, reliability, and long-term value.

|

|

|

|

|

|

FAQs

Q1: What is the purity level of your molybdenum sheets?

A1: Our sheets have a minimum purity of 99.95%, ensuring optimal mechanical and chemical stability.

Q2: Can you provide customized dimensions?

A2: Yes, we produce molybdenum sheets according to customer drawings and special tolerances.

Q3: What surface finishes are available?

A3: We offer polished, rolled, and chemically cleaned surfaces based on end-use requirements.

Q4: How do you ensure product quality?

A4: Every production stage follows ISO 9001:2015 standards, with full inspection reports included.

Q5: What industries commonly use this material?

A5: It’s widely used in semiconductor, vacuum furnace, aerospace, and chemical processing industries.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email