- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

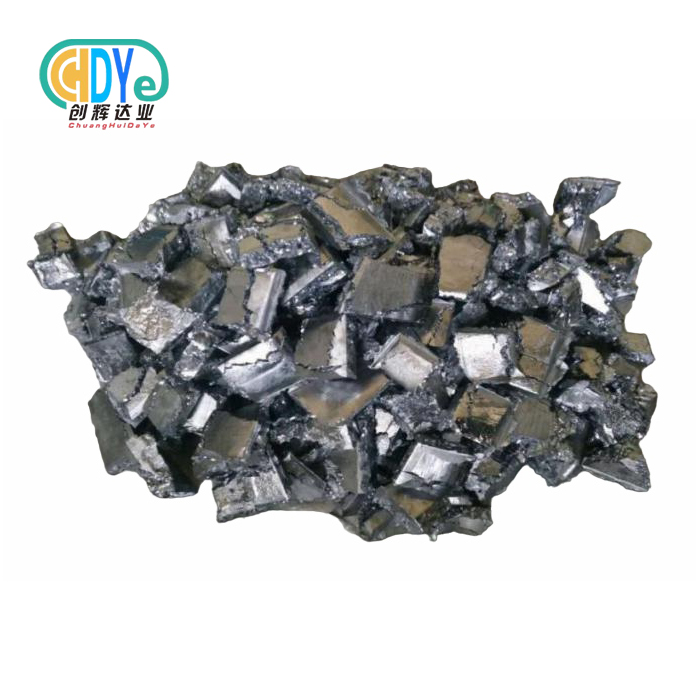

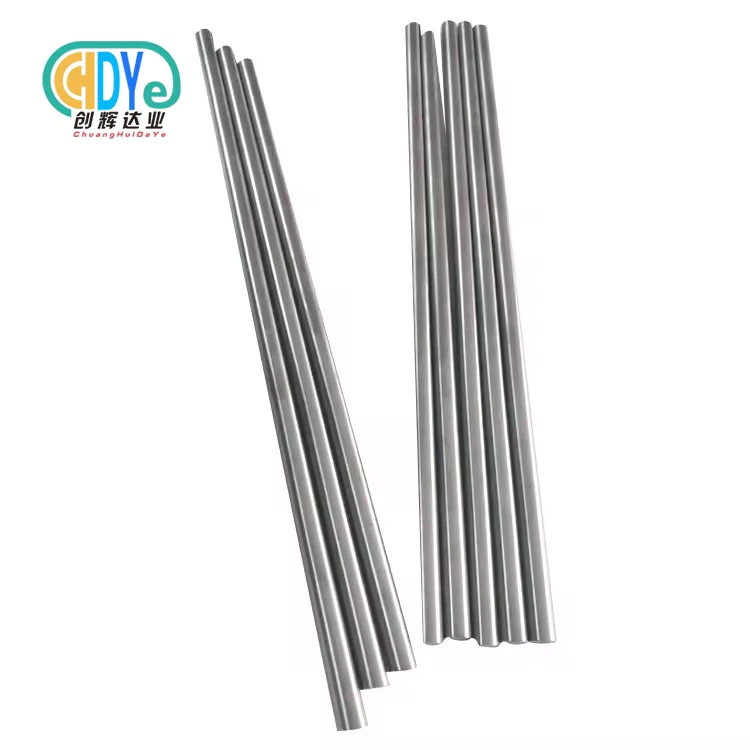

customized niobium target

2. Purity: 99.95%

3. Standard: ASTM B 392

4. Dimensions: Diameter: 3-120mm* Length:<2m

Production introduction

Looking for high-quality niobium targets tailored to your exact specifications? Our customized niobium target solutions deliver exceptional performance for your most demanding applications. With purity levels ranging from 99.8% to 99.99% and precision machining capabilities, we provide niobium targets that meet your unique requirements. Whether you need specific dimensions, surface finishes, or alloy compositions, our customized niobium target manufacturing ensures optimal results for your coating processes.

Key Features and Benefits

Our niobium targets offer outstanding performance characteristics that make them ideal for various industrial applications:

Superior Corrosion Resistance: Withstands attack from acids, alkalis, and chemical substances for long-term stability.

Exceptional High-Temperature Performance: With a melting point of 2,477°C, our targets maintain stability in extreme conditions.

High Strength and Durability: Despite high density, excellent strength properties meet demanding application requirements.

Outstanding Chemical Stability: No unwanted reactions or grain boundary diffusion during extended use.

Precision Manufacturing: CNC machining accuracy of ±0.005 mm ensures consistent performance.

Technical Specifications

| Parameter | Specification |

|---|---|

| Grades Available | R04200, R04210 |

| Purity Range | 99.8% - 99.99% |

| Density | 8.5 g/cm³ |

| Standard Compliance | ASTM B 392 |

| Minimum Diameter | 5 mm |

| Minimum Thickness | 1mm |

| Surface Finish | Ra ≤0.4 μm |

| Theoretical Density | ≥99.9% with HIP |

| Process | Cold rolled, Hot rolled, Extruded |

| Product Features |

Excellent Corrosion Resistance Good resistance to effect of heat |

| Packing | Foam material inside, wooden box outside |

| Payment terms | 30% TT in advance, 70% balance before shipment |

Chemical composition

|

Material |

Main elements(%) |

Impurities (Maximum %) |

||||||||||

|

Nb |

Fe |

Si |

Ni |

W |

Mo |

Ti |

Ta |

O |

C |

H |

N |

|

|

RO4200 |

Remainder |

0.004 |

0.004 |

0.002 |

0.005 |

0.005 |

0.002 |

0.07 |

0.015 |

0.0040 |

0.0015 |

0.003 |

|

RO4210 |

Remainder |

0.01 |

0.01 |

0.005 |

0.02 |

0.01 |

0.004 |

0.10 |

0.02 |

0.01 |

0.0015 |

0.01 |

Mechanical Properties

|

Grade |

Tensile strength psi(MPa), ≥ |

Yield strength δ0.2, psi (MPa),≥ |

Elongation in 1"/2" gage length, %, ≥ |

|

|

>=0.010 |

<0.010 |

|||

|

RO4200 RO4210 |

18000 (125) |

12000 (85) |

25 |

20 |

Available Grades and Materials

We offer various niobium grades and alloy compositions to suit different applications:

- Pure Niobium: R04200 and R04210 grades

- NbTi Alloys: For superconducting applications

- NbZr Alloys: Enhanced performance characteristics

- AgCu 72/28 Bonding Interface: For improved durability and thermal management

Manufacturing Process

Our advanced manufacturing process ensures consistent quality:

- Raw Material Selection: High-purity niobium sourcing

- Melting and Casting: Controlled atmosphere processing

- Hot Isostatic Pressing (HIP): Achieves ≥99.9% theoretical density

- Heat Treatment: 600-850°C stress relief treatment

- Precision Machining: CNC machining for exact specifications

- Surface Finishing: Cold rolled or machined surfaces available

- Quality Testing: Comprehensive inspection before delivery

|

|

|

|

|

|

|

|

Applications and Industries

Semiconductor Manufacturing: Physical vapor deposition for chip production and thin film applications.

Display Technology: LCD manufacturing and transparent conductive layers.

Solar Energy: Photovoltaic cell production and thin-film battery manufacturing.

Medical Devices: Dental implants and biocompatible components due to excellent corrosion resistance.

Research and Development: Materials science, superconducting materials, and catalyst preparation.

Electronics: Various electronic components and advanced semiconductor devices.

Product Features in Detail

Surface Quality: Our targets feature superior surface finishes with Ra ≤0.4 μm, perfect for optical coating applications.

Microstructure Control: Advanced processing ensures uniform grain structure for consistent sputtering performance.

Thermal Management: Optional AgCu bonding interfaces provide excellent heat dissipation during high-power operations.

Flexibility: Custom shapes including planar, tubular, and stepped configurations available.

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Quality Assurance and Testing

We maintain strict quality control throughout production:

- Chemical composition analysis

- Density measurements

- Surface roughness testing

- Dimensional inspection

- Microstructural examination

- Performance validation testing

|

|

|

OEM & Customization Services

Our experienced team works closely with you to develop the perfect customized niobium target solution. We offer:

- Custom alloy compositions

- Specific dimensional requirements

- Unique surface treatments

- Special packaging requirements

- Technical support and consultation

Packaging and Shipping

We ensure safe delivery with professional packaging:

- Protective foam padding

- Moisture-resistant materials

- Custom crating for large targets

- International shipping capabilities

- Tracking and insurance options

Why Choose Us

With over 30 years of experience in rare metal processing, Shaanxi Chuanghui Daye Metal Material Co., Ltd. delivers exceptional quality and service. Located in China's "Titanium Capital," we combine extensive expertise with advanced manufacturing capabilities. Our products serve customers in over 50 countries worldwide, ensuring reliable quality and competitive pricing.

1.You can get the perfect material according to your requirement at the least possible price.

2.We offer FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

3. we provide raw material test certificate to the final dimensional statement.(Reports will show on requirement)

4. You can get stock alternatives, usually stock size we can arrange 1-3 days quick delivery to save your time.

5.We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

|

|

|

|

|

|

FAQs

Q: What is the typical lead time for custom orders?

A: Lead times vary based on specifications, typically 2-3 weeks for standard customizations.

Q: Can you provide material certificates?

A: Yes, we provide complete material certificates including chemical composition and test reports.

Q: What is the minimum order quantity?

A: MOQ depends on specifications. Contact us for specific requirements.

Q: Do you offer technical support?

A: Absolutely. Our experienced team provides comprehensive technical assistance.

Contact Us

Ready to discuss your specific requirements? Contact our technical team today for expert guidance on selecting the right customized niobium target for your application.

Email: info@chdymetal.com

Mob./what's app: 86-18049386902

Let us help you achieve superior results with our precision-engineered niobium target solutions.

Learn about our latest products and discounts through SMS or email