- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

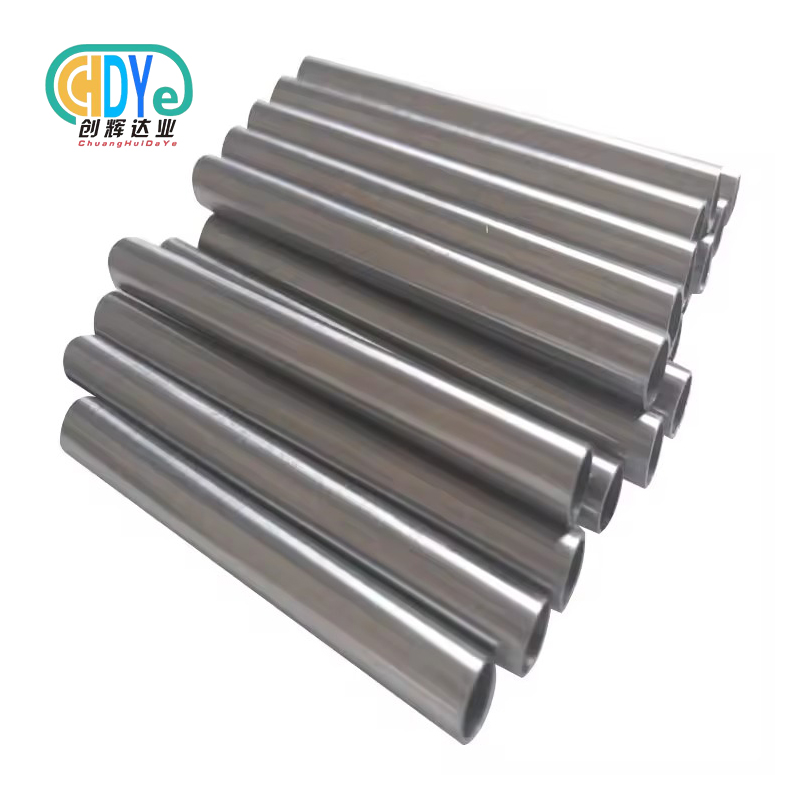

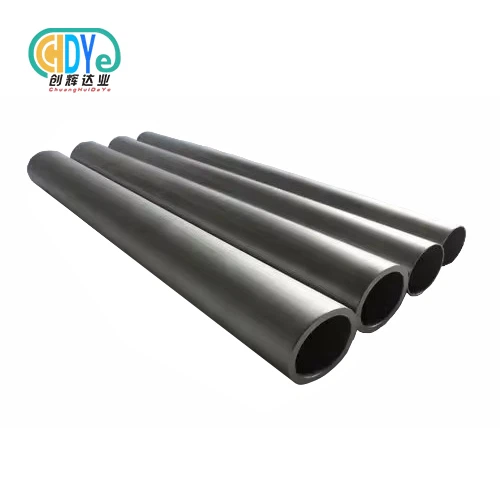

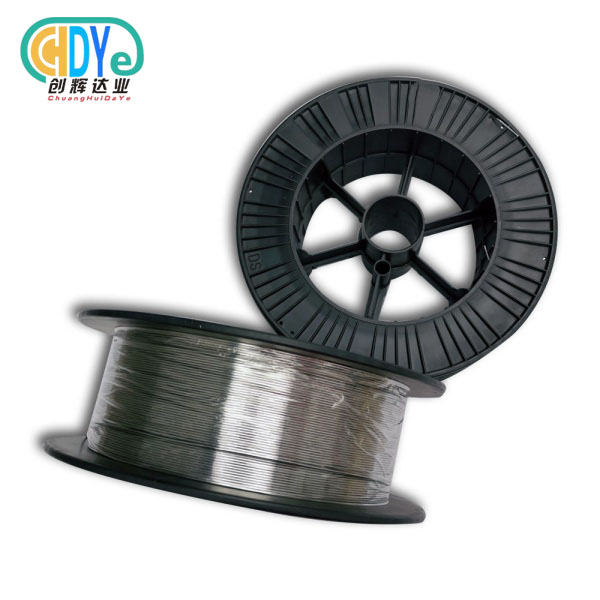

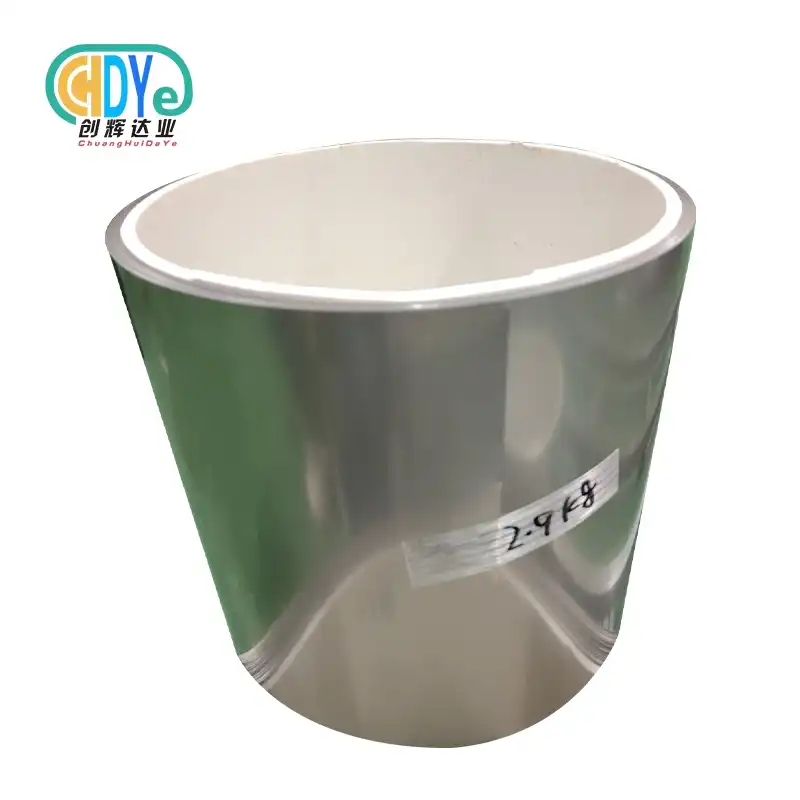

tantalum plate sheet

2. Thickness: 0.1–50 mm

3. Width: up to 1000 mm

4. Length: up to 3000 mm

5. Density: 16.65 g/cm³

6. Tensile strength: 200–300 MPa

7. Applications: Industrial, chemical

Product Introduction

Our premium tantalum plate sheet delivers exceptional performance for your most demanding industrial applications. Made from 99.9% pure tantalum, these sheets offer unmatched corrosion resistance and thermal stability. You'll find our products perfect for chemical processing, electronics manufacturing, and high-temperature environments. Each sheet undergoes rigorous quality testing to ensure consistent performance. Our experienced team has over 30 years of expertise in rare metal manufacturing. We serve customers across 50+ countries worldwide with reliable, high-grade materials.

Key Features and Benefits

- Superior Corrosion Resistance: Withstands aggressive acids and chemicals

- High Temperature Stability: Maintains properties up to 3000°C

- Excellent Ductility: Easy to form and machine for complex applications

- Bio-compatibility: Safe for medical and pharmaceutical uses

- Low Thermal Expansion: Maintains dimensional stability under temperature changes

- Outstanding Electrical Properties: Ideal for electronic components

Technical Specifications

| Property | Value |

|---|---|

| Alloy Composition | Ta >99.9% |

| Thickness Range | 0.1–50 mm |

| Maximum Width | up to 1000 mm |

| Maximum Length | up to 3000 mm |

| Density | 16.65 g/cm³ |

| Tensile Strength | 200–300 MPa |

| Melting Point | 3017°C |

| Grade | R05200, R05240, R0525, R05255 |

| Standard: | ASTM B708 |

| Type | all available |

| Size: |

Thickness 0.5-20mm*width50-1200*Length30-2500mm |

Available Grades and Materials

We offer various tantalum grades to meet your specific needs:

- Pure Tantalum (R05200): 99.9% purity for maximum corrosion resistance

- Tantalum-Tungsten Alloy (2.5% W): Enhanced strength for high-stress applications

- Tantalum-Tungsten Alloy (10% W): Superior mechanical properties for extreme conditions

Each grade comes with detailed material certificates and test reports.

Manufacturing Process

Our advanced manufacturing process ensures consistent quality:

|

|

|

|

|

|

|

|

Applications and Industries

Our tantalum plate sheet serves diverse industries:

- Raw Material Selection: Premium tantalum powder sourcing

- Vacuum Melting: Controlled atmosphere processing

- Rolling and Forming: Precision thickness control

- Heat Treatment: Optimized annealing for desired properties

- Surface Finishing: Clean, oxide-free surfaces

- Quality Inspection: Comprehensive testing and certification

- Chemical Processing: Reactor vessels, heat exchangers, piping systems

- Electronics: Capacitor manufacturing, semiconductor equipment

- Medical: Surgical implants, prosthetics, diagnostic equipment

- Aerospace: High-temperature components, radiation shielding

- Energy: Nuclear applications, solar panel manufacturing

- Research: Laboratory equipment, analytical instruments

-

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

We maintain tight tolerances for consistent performance:

- Thickness Tolerance: ±0.05mm for sheets under 5mm

- Width Tolerance: ±2mm

- Length Tolerance: ±5mm

- Flatness: Better than 2mm per meter

- Surface Finish: Ra 0.8μm or better

Product Features in Detail

Your projects benefit from our superior material properties. The exceptional corrosion resistance protects equipment in harsh chemical environments. High melting point enables use in extreme temperature applications. Excellent workability allows complex forming operations. Bio-compatibility makes it ideal for medical applications. Low outgassing properties suit vacuum applications perfectly.

Our tantalum plate sheet maintains stability under thermal cycling. The material resists stress corrosion cracking effectively. You get consistent electrical properties throughout the sheet. Surface quality meets the highest industrial standards.

Quality Assurance and Testing

We implement comprehensive quality control:

- Chemical Analysis: ICP-MS verification of composition

- Mechanical Testing: Tensile, hardness, and bend tests

- Surface Inspection: Visual and dimensional checks

- Non-Destructive Testing: Ultrasonic and eddy current inspection

- Traceability: Complete documentation from raw material to finished product

Every batch includes detailed test certificates and material reports.

OEM & Customization Services

Our flexible manufacturing accommodates your specific requirements:

- Custom dimensions and tolerances

- Special surface treatments

- Precision cutting and machining

- Forming and bending services

- Small batch production capabilities

- Technical consultation and support

We work closely with your engineering team to optimize material specifications.

Packaging and Shipping

Your tantalum plate sheet arrives safely with our protective packaging:

- Individual sheet protection with foam padding

- Moisture-resistant wrapping

- Sturdy wooden crates for large orders

- Complete documentation package

- Worldwide shipping capabilities

- Express delivery options available

We ensure damage-free delivery to your facility.

Why Choose Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd. brings you:

- 30+ Years Experience: Deep expertise in rare metals

- Global Reach: Serving 50+ countries worldwide

- Quality Focus: Rigorous testing and certification

- Competitive Pricing: Direct manufacturer pricing

- Technical Support: Expert application guidance

- Reliable Delivery: On-time shipment guarantee

Located in China's "Titanium Capital," we leverage regional expertise and resources.

FAQs

Q: What's the minimum order quantity?

A: We accommodate orders from single sheets to large production runs.

Q: Can you provide material certificates?

A: Yes, complete test reports and certificates accompany every shipment.

Q: Do you offer technical support?

A: Our experienced engineers provide application guidance and technical consultation.

Q: What's the typical lead time?

A: Standard products ship within 1-2 weeks; custom orders require 2-3weeks.

Contact Us

Ready to discuss your tantalum plate sheet requirements? Our expert team stands ready to help you select the perfect material solution.

Email: info@chdymetal.com

Mob./what's app: 86-18049386902

Contact us today for technical specifications, pricing, and delivery information. We look forward to supporting your next project with our premium tantalum materials.

Learn about our latest products and discounts through SMS or email