- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

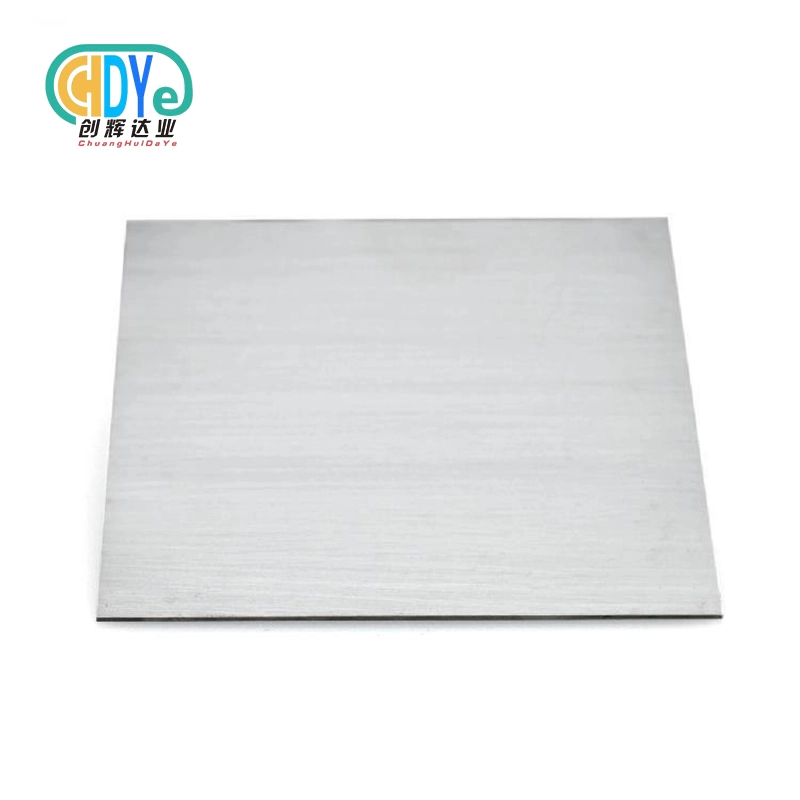

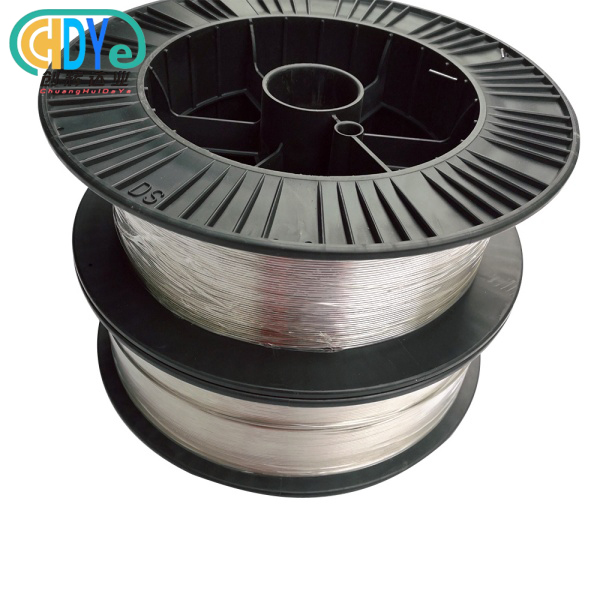

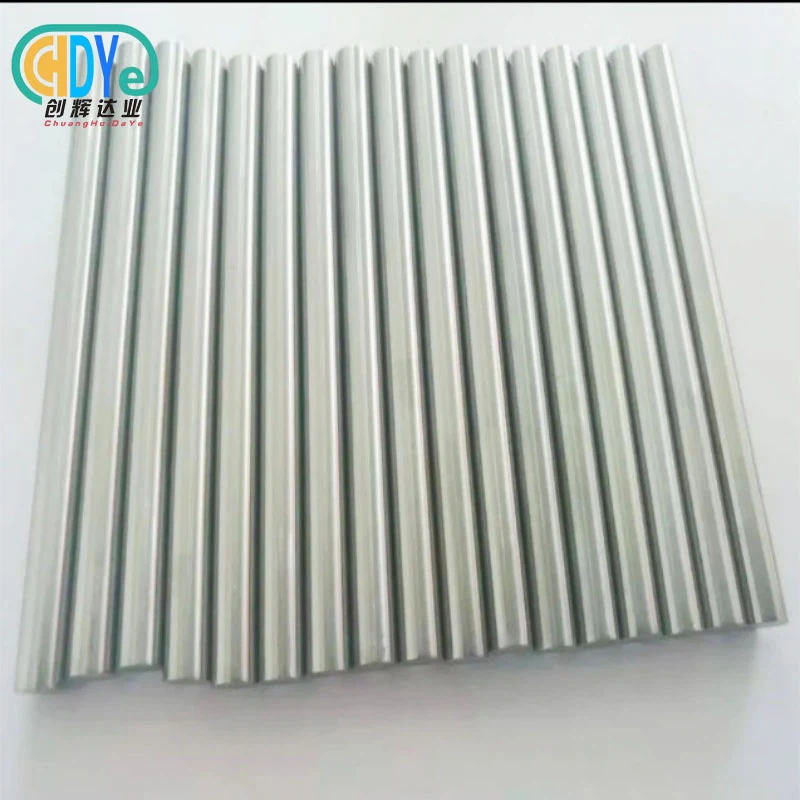

High Purity Tantalum Wire

Product Introduction

Chdymetal can offer high purity tantalum wire with various purities and sizes. Tantalum wire is made according to ASTM B365, if you need customized service just contact us. More details information as below:

Specification:

|

Product Name |

High purity tantalum wire |

|

Material |

Tantalum Niobium wire R05240 (Ta-40Nb) Pure tantalum: R05200, R05400; TantalumTungsten Rod / Bar R05252 (Ta-2.5W), R05255 (Ta-10W). |

|

Standard |

ASTM B365 |

|

Service |

Customized OEM, OEM/ODM/Customized, ODM Available |

|

Packing |

Wooden box |

|

Delivery time |

Stock size will be 1-5 days, normal production time is about 15 days |

|

Payment terms |

30%TT in advance,70% balance before shipment |

Application Advantages

High Purity Tantalum Wire offers exceptional corrosion resistance, high melting point, and superior ductility, making it ideal for demanding environments. It is widely used in electronics, chemical processing, aerospace, and medical device manufacturing. Thanks to its outstanding conductivity and biocompatibility, Tantalum Wire is also a preferred material for capacitors, heaters, and sputtering targets.

Key Advantages:

- Excellent corrosion and oxidation resistance

- Stable performance in high-temperature and vacuum conditions

- Superior ductility and mechanical strength

- Exceptional purity and uniform grain structure

- Ideal for both precision machining and microelectronic components

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

At Shaanxi Chuanghui Daye Metal Material Co., Ltd., High Purity Tantalum Wire is produced under strict quality standards and advanced process control systems to ensure high consistency and purity.

Production Process Flow:

- Raw Material Selection: Certified high-purity tantalum ingots are used.

- Vacuum Electron Beam Melting: Achieves ultra-high purity and uniform microstructure.

- Hot Forging and Rolling: Enhances mechanical strength and elongation.

- Precision Drawing and Annealing: Produces fine wire diameters with excellent surface quality.

- Final Inspection and Packaging: Each batch is tested and vacuum-packed for protection.

|

|

|

|

|

|

|

|

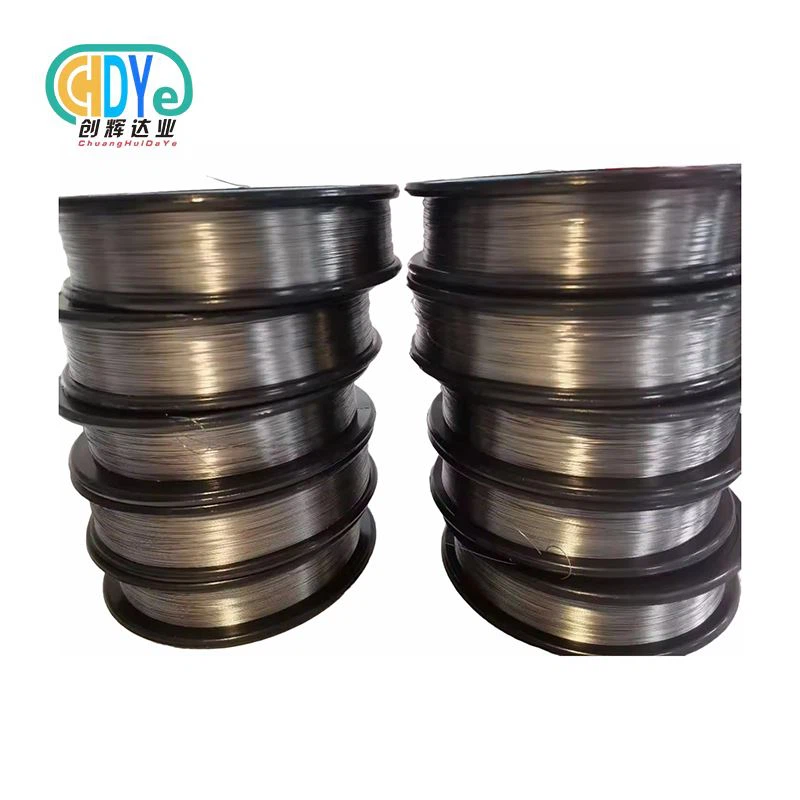

Quality Control & Inspection

Quality is central to our production philosophy. Our High Purity Tantalum Wire undergoes multi-stage inspection and testing to ensure compliance with ASTM, ISO, and GB standards.

Inspection Scope Includes:

- Chemical Composition Analysis (ICP-OES) to verify purity levels ≥99.95%

- Mechanical Property Testing (tensile strength, elongation, hardness)

- Surface Finish Examination for uniformity and smoothness

- Dimensional Accuracy Inspection using precision instruments

- Non-Destructive Testing (Ultrasonic & Eddy Current) for internal integrity

R&D and Customization

With over 30 years of industry experience, Shaanxi Chuanghui Daye Metal Material Co., Ltd. continuously innovates in rare metal material technology. Our R&D focuses on:

- Developing high-purity tantalum alloys with improved mechanical strength

- Optimizing wire drawing and annealing techniques for finer diameters

- Customizing wire grades and structures for aerospace and medical use

We also provide custom diameter, tensile strength, and surface finish options to meet specific client requirements. OEM and ODM customization are fully supported.

Packaging & Global Logistics

Packaging Details:

- Vacuum-sealed or anti-rust protective film

- Soft foam padding and moisture-resistant wrapping

- Export-grade wooden boxes for heavy shipments

- Clear product labeling with size, grade, and batch number

Global Logistics:

- Reliable air, sea, and land shipping partners

- Fast 7-day delivery for standard specifications

- Full documentation support for international customs clearance

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

We offer comprehensive OEM and customization services to support your production and project needs:

- Custom wire diameters and coil weights

- Tailored chemical compositions for specific applications

- Prototype to mass production flexibility

- Engineering and technical consultation support

Our solutions are designed to help customers reduce cost, improve efficiency, and ensure long-term performance reliability.

Inspection Process

Every stage production is strictly controlled:

- Incoming Material Inspection – Verify raw tantalum purity.

- In-Process Quality Monitoring – Continuous mechanical and surface testing.

- Dimensional Verification – Check tolerance within ±0.01 mm.

- Final Quality Assurance – Complete documentation and photo records.

- Packaging Inspection – Ensure product safety during transport.

This rigorous process ensures every wire meets or exceeds international quality expectations.

Why Choose Us

- 30+ years of expertise in rare metal manufacturing

- ISO 9001:2015 certified quality management system

- Advanced production equipment (EB furnace, annealing, precision rolling)

- Customized R&D support for specialized applications

- Global delivery to 50+ countries with proven reliability

- Fast response and technical consultation within 24 hours

Choose Shaanxi Chuanghui Daye Metal Material Co., Ltd. for High Purity Tantalum Wire solutions that combine reliability, precision, and exceptional performance.

|

|

|

|

|

|

FAQs

Q1: What is the purity level of your tantalum wire?

A1: The standard purity reaches 99.95%, while ultra-high purity up to 99.99% can be produced according to customer requirements.

Q2: What diameter ranges do you offer?

A2: Wire diameters are available from 0.1 mm to 5.0 mm, and customized dimensions can be supplied upon request.

Q3: Do you accept sample or small-quantity orders?

A3: Yes, we provide prototype and small-batch production to support research, testing, or new product development.

Q4: What is your typical lead time for delivery?

A4: Standard specifications are usually shipped within 7 days, while custom-made products may vary depending on the order details.

Q5: Which industries commonly apply your tantalum wire products?

A5: They are extensively used in electronics, aerospace, chemical processing, medical device manufacturing, and other high-performance engineering fields.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email