- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Seamless Niobium Pipe

Product Introduction

The Seamless Niobium Pipe produced by Shaanxi Chuanghui Daye Metal Material Co., Ltd. is manufactured from high-purity niobium using advanced melting, extrusion, and precision machining techniques. Known for its superior corrosion resistance, high melting point, and excellent ductility, this pipe is ideal for demanding environments such as high-temperature and vacuum systems. Each Seamless Niobium tube conforms to ASTM, AMS, and ISO standards, ensuring stable performance and long service life in critical industrial applications.

Chdymetal can provide seamless niobium pipe, niobium titanium alloy tube, welded pipe and tube, we stocks a various of size and quantity. If you need customized service pls feel free to contact us.

Niobium has a density of 8.57g/cm³, a melting point of 2477°C, and a boiling point of 4744°C. Niobium is a silver-gray, soft and ductile rare high melting point metal. Because niobium has good superconductivity, high melting point, corrosion resistance, wear resistance and other characteristics, it is widely used in steel, superconducting materials, aerospace, atomic energy and other fields.

Seamless Niobium pipe we can supply as below information:

|

Out diameter |

3.0-100mm |

|

Wall thickness |

0.5-5.0mm |

|

Length |

200mm-6000mm/ or as your requiremets |

| Standard | ASTM B394 |

| Type | seamless tube |

| Payment term | TT inadvance |

| MOQ | we support sample order just send me your inquiry |

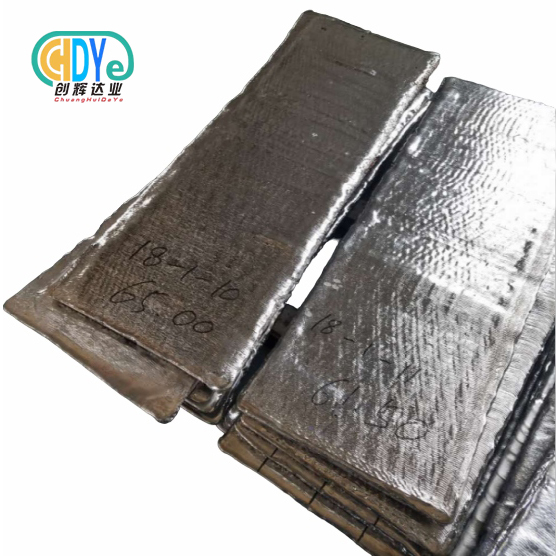

seamless niobium pipe packing

Seamless Niobium pipe wrapped in woven bag, and the external wooden packing cable ties are tightened to ensure safety during transportation.

seamless niobium pipe application

*Niobium pipe are used for high-pressure sodium lamp production.

*Niobium pipe can be used as heat exchange pipe in the heat exchanger; can be used as thermometer protection pipe in the petrochemical industry.

Related niobium products

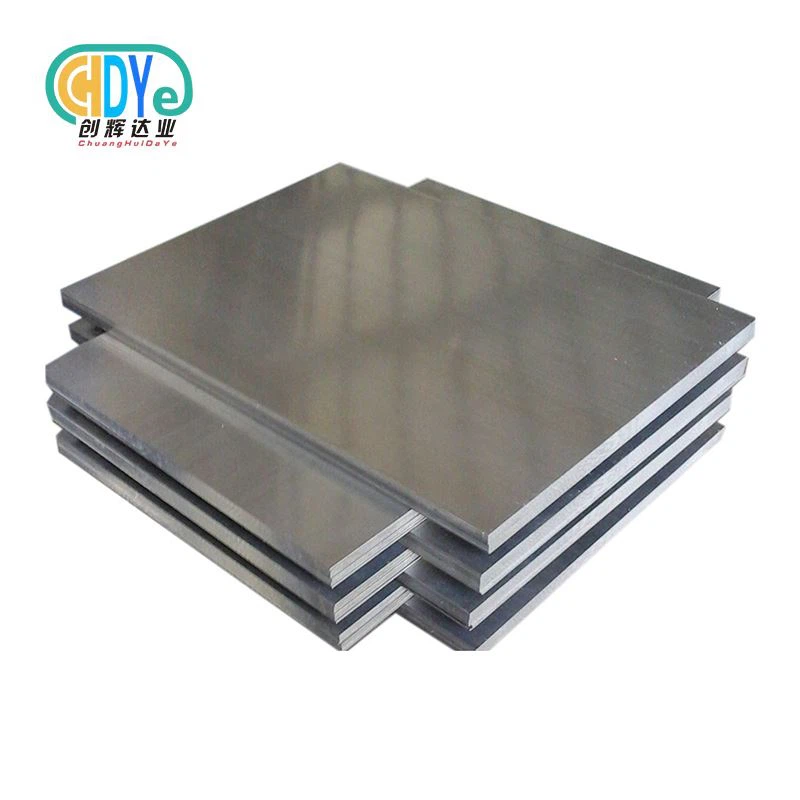

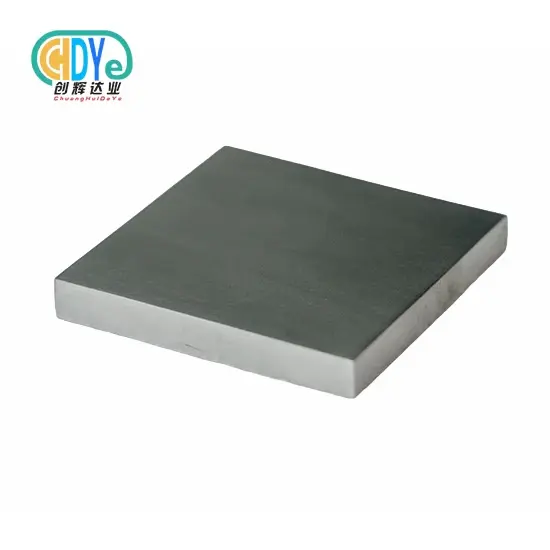

Niobium alloy plate

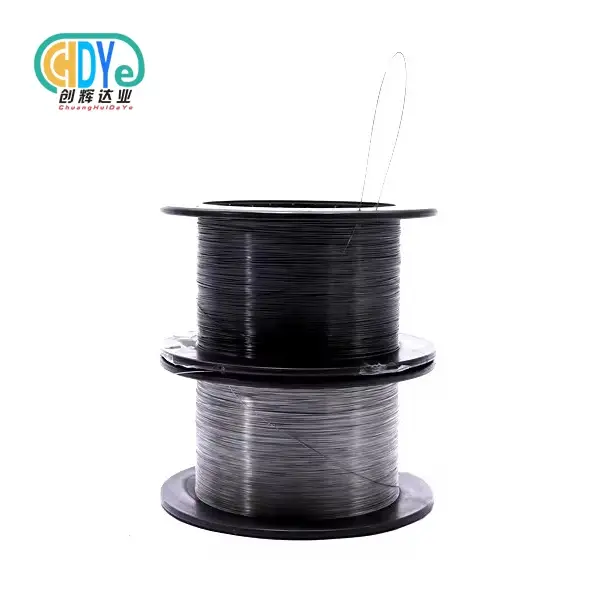

Pure Niobium Wire

Application Advantages

The Seamless Niobium Pipe is widely used across multiple industries due to its exceptional physical and chemical stability.

Key application areas include:

- Aerospace & Defense: Utilized in jet engine components, heat exchangers, and rocket propulsion systems.

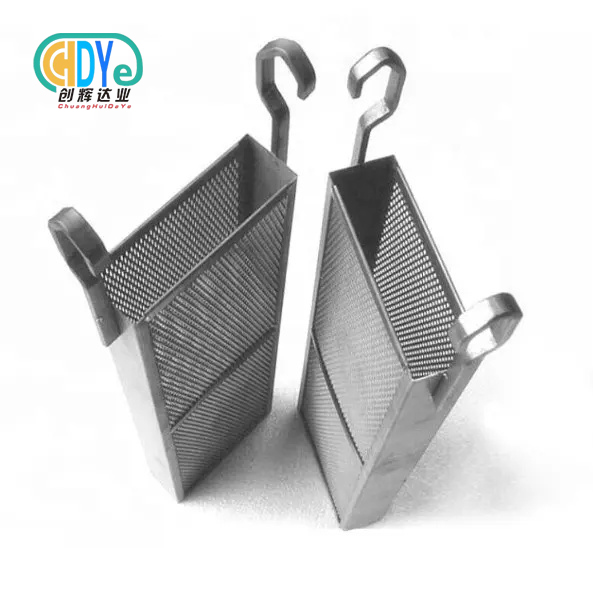

- Electronics & Semiconductor: Applied in sputtering targets, vacuum devices, and electronic tube parts.

- Chemical Processing: Resistant to acids and alkalis, making it ideal for reactors and chemical transfer systems.

- Medical Equipment: Suitable for surgical instruments, implants, and medical device manufacturing due to its biocompatibility.

- Energy & Environmental Engineering: Used in heat-resistant and corrosion-resistant systems in power and environmental projects.

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

The Seamless Niobium Pipe is produced through a series of precision-controlled stages:

- Raw Material Inspection: High-purity niobium ingots are tested for chemical composition and uniformity.

- Vacuum Melting: Melting in an electron beam or vacuum furnace ensures purity and structural integrity.

- Hot Forging & Extrusion: The material is hot-forged and extruded into pipe form under controlled conditions.

- Cold Working & Annealing: Improves mechanical strength and dimensional accuracy.

- Precision Machining: Achieves tight tolerances and smooth internal/external surfaces.

- Final Inspection & Cleaning: Ensures all pipes meet technical and visual standards before delivery.

|

|

|

|

|

|

|

|

R&D and Customization

Shaanxi Chuanghui Daye maintains a professional R&D team dedicated to the continuous improvement of Seamless Niobium Pipe manufacturing. Our engineers work closely with clients to provide:

- Customized pipe dimensions and tolerances

- Alloy modifications for special performance requirements

- Prototype development for new projects

- Surface treatment and finishing options

- Through ongoing innovation, we enhance material purity, precision forming, and high-temperature performance.

Packaging & Global Logistics

To ensure product safety and integrity, each Seamless Niobium Pipe is carefully packaged using:

- Vacuum or anti-rust film wrapping to prevent oxidation

- Foam protection to minimize vibration damage during transport

- Export-standard wooden cases for secure shipment

All packages are clearly labeled with product details, heat numbers, and specifications.

Chuanghui Daye provides global logistics through reliable sea, air, and land transport partners, guaranteeing timely delivery to over 50 international markets.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

We offer comprehensive OEM and ODM solutions for Seamless Niobium Pipe, including:

- Custom grades, wall thickness, and lengths

- Machining according to drawings or samples

- Small-batch or mass production capabilities

- Technical consultation for material selection and application optimization

- Our experienced engineers ensure that every customized order meets or exceeds the client’s technical and operational expectations.

Inspection Process

Each batch of Seamless Niobium Pipe passes through a detailed inspection workflow:

- Incoming Material Verification

- Process Control Monitoring

- Intermediate Dimensional Checks

- Final Product Testing (Mechanical & Chemical)

- Packaging and Label Verification

This multi-level inspection guarantees that every pipe maintains consistent quality and traceability from raw material to final delivery.

Why Choose Us

- 30+ Years of Industry Expertise in rare metal processing

- ISO 9001:2015 Certified Quality System

- Advanced Facilities including electron beam furnaces and precision rolling machines

- Comprehensive OEM Service with technical consultation

- 7-Day Fast Delivery for standard specifications

- Global Export Experience to over 50 countries

Shaanxi Chuanghui Daye is your reliable partner for precision Seamless Niobium Pipe solutions, offering superior performance, consistent quality, and global supply reliability.

|

|

|

|

|

|

FAQs

Q1: What standards do your Seamless Niobium Pipes comply with?

A1: All pipes are produced in accordance with ASTM B394, AMS, ISO, and GB standards.

Q2: Can you provide customized dimensions?

A2: Yes, we can produce according to customer drawings, samples, or special dimensional requirements.

Q3: How do you ensure product quality?

A3: Each Seamless Niobium Pipe undergoes multi-stage inspection, including ultrasonic testing, dimensional control, and chemical analysis.

Q4: What are your typical delivery times?

A4: Standard products can be shipped within 7 days; customized orders are arranged according to complexity and quantity.

Q5: Do you provide international shipping support?

A5: Yes, we offer air, sea, and land logistics solutions to ensure safe and efficient global delivery.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email